Circumferential radial multipath oil cooling system for high-speed motor

An oil cooling system and high-speed motor technology, applied in the electrical field, can solve problems such as uneven temperature distribution and rotor temperature rise, and achieve the effects of weakening the influence, reducing the working temperature rise, and reducing the axial temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

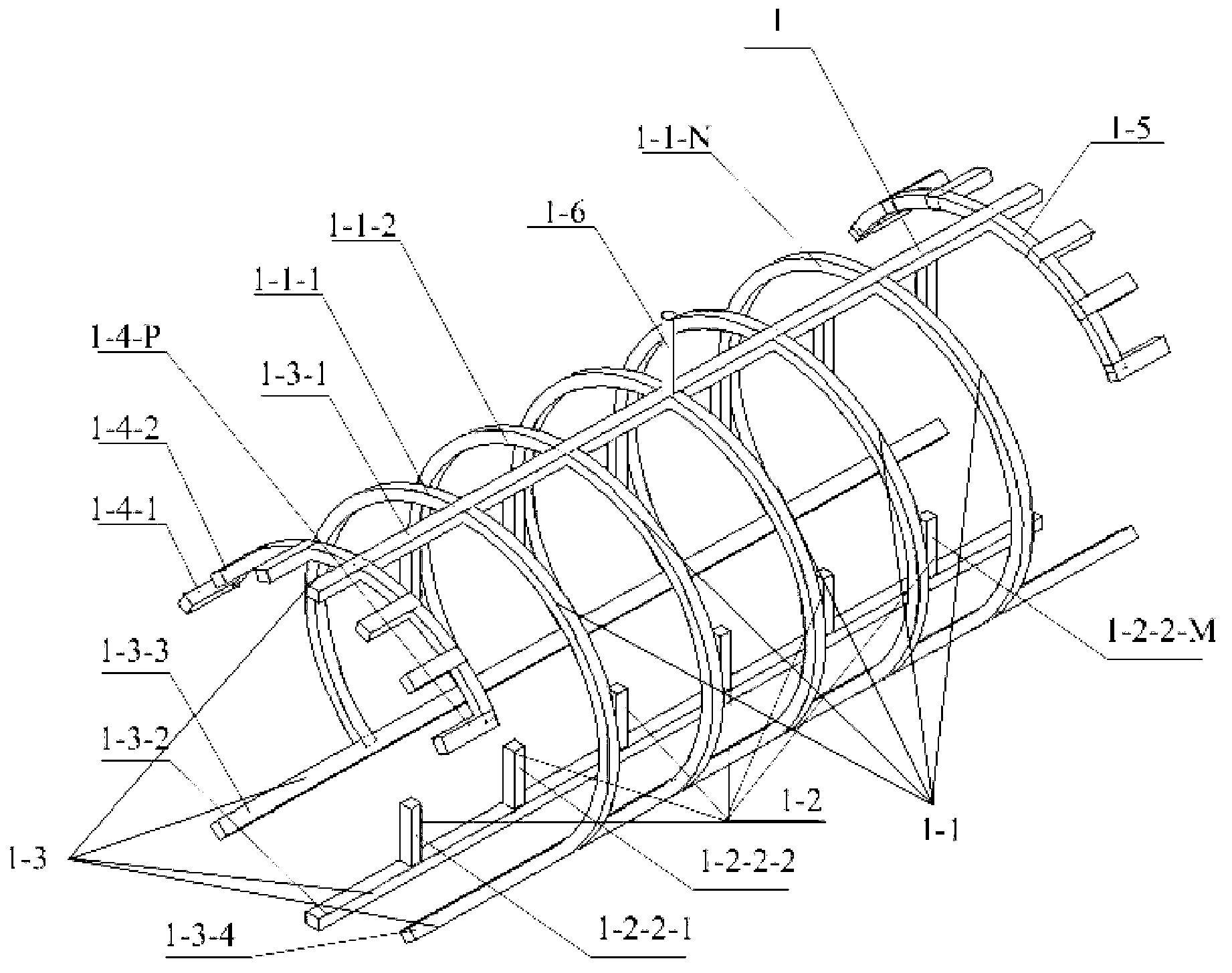

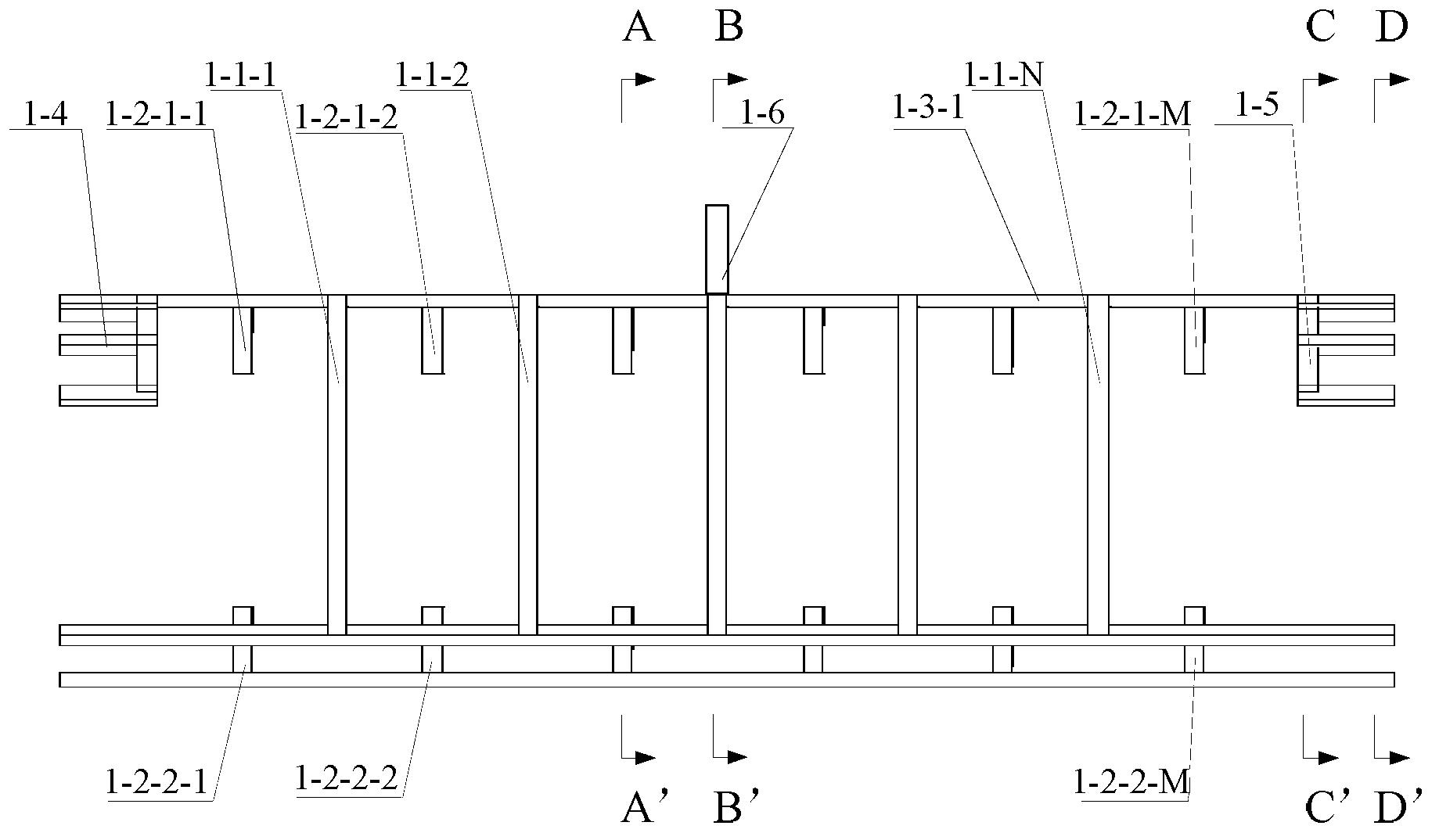

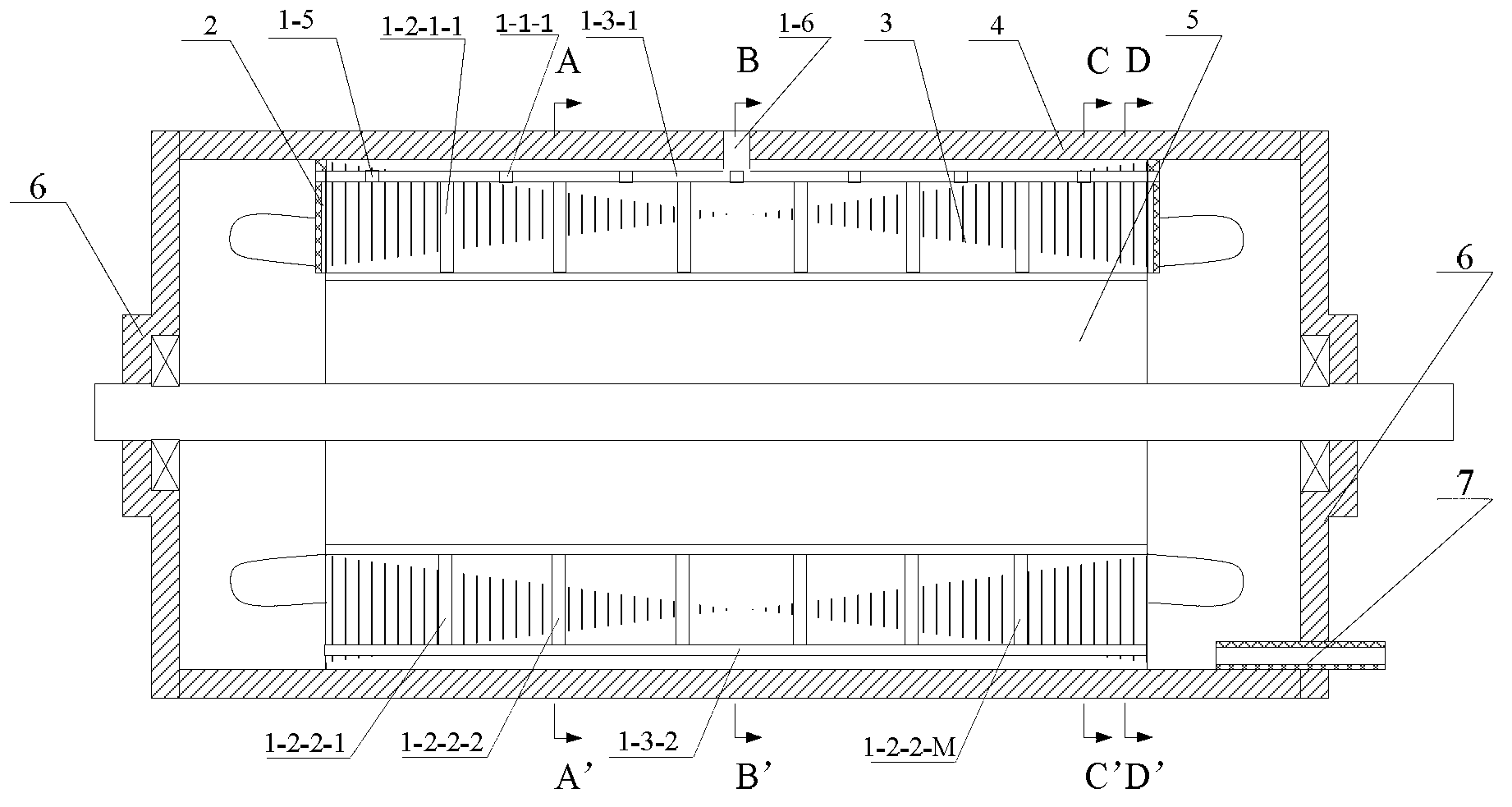

[0025] Embodiment: high-speed motor circumferential radial multi-channel oil cooling system, such as Figure 1 to Figure 10 As shown, the device includes: stator core 3, rotor 4, casing 5, end cover 6;

[0026] The stator core of the motor is equipped with a multi-channel oil cooling system 1;

[0027] An oil inlet is opened at the axial middle position of the stator frame, and the oil inlet is connected with the oil inlet channels 1-6 of the multi-channel oil cooling system 1;

[0028] An axial cooling passage 1-3 is opened at a certain distance from the iron core of the stator yoke to the outer circle of the iron core, including the top axial cooling passage 1-3-1 located at the vertical upper part of the stator iron core, and the bottom axial cooling passage located at the vertical lower part of the stator iron core. To the cooling passage 1-3-2 and the middle and lower axial cooling passage 1-3-3 and the middle and lower axial cooling passage 1-3-4 located in the lower pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com