Nuclear fuel rod plenum spring assembly

A nuclear fuel element and nuclear fuel technology, applied in the field of fuel rod components, can solve problems such as inability to provide uniform pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

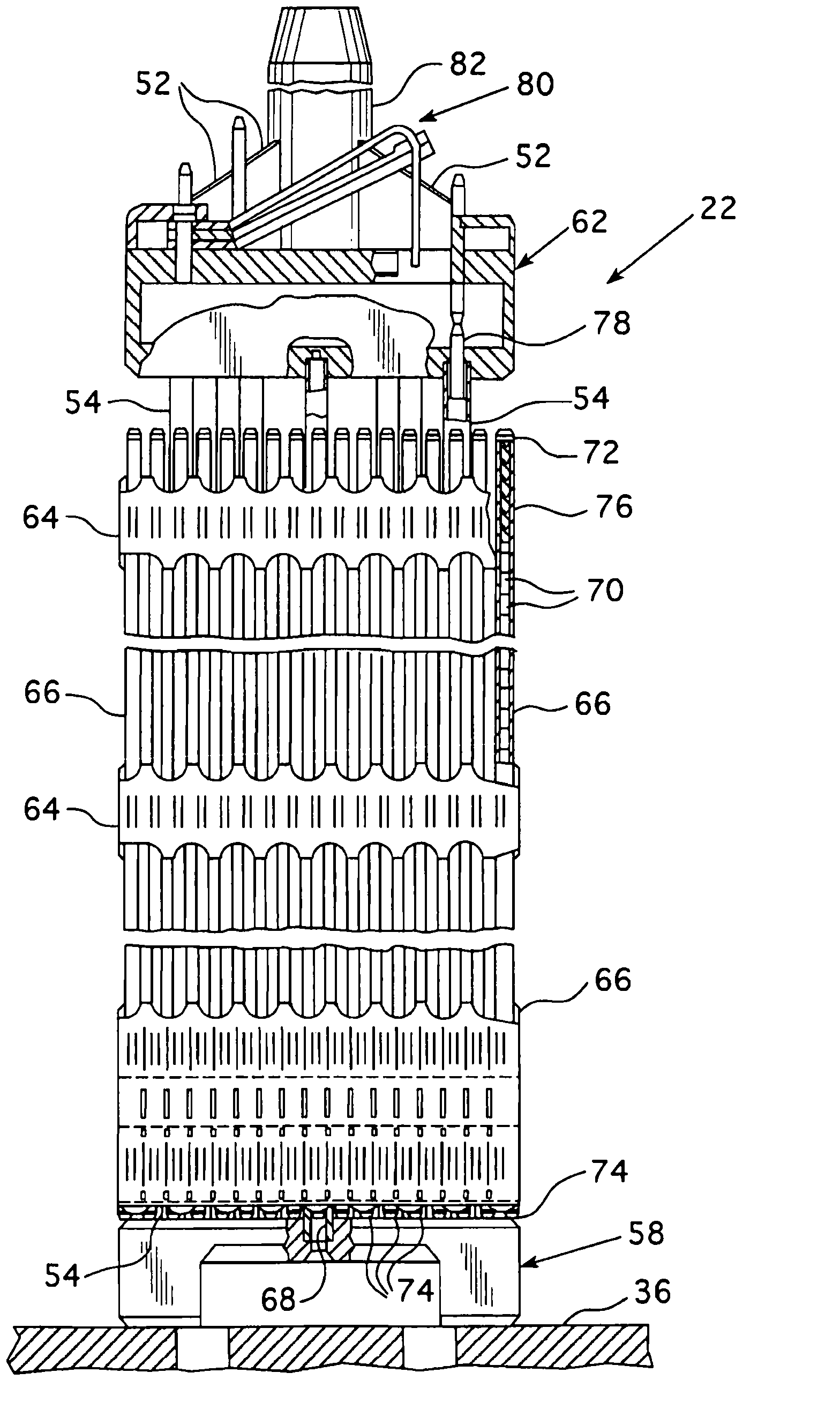

[0031] To achieve the foregoing objectives, the present invention introduces an intermediate section between the plenum spring and the top pellet of the fuel pellet stack, thereby creating an even contact distribution and reducing debris movement between the fuel rod plenum and the pellet stack possibility. A new intermediate element between the top core and the spring end coils is designed to provide even pressure distribution and reduce the possibility of debris migration. Ideally, the element is attached to an existing air chamber spring. In one embodiment, such as Figure 5 and 6 As shown, the intermediate element is a threaded spacer 86 that forms the interface between the plenum spring and the top surface of the top pellet. The spacer 86 is designed to provide uniform contact pressure on the top surface of the top pellet over its substantially flat head 88 and to reduce the possibility of movement of small pellet fragments. The threaded spacer also has features that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com