Vibrating element, optical scanning device, and image forming device and image projection device using same

A technology of optical scanning device and vibrating element, used in electromechanical devices, projection devices, electrical components, etc., can solve problems such as abnormal vibration and inability to scan, and achieve the effect of improving flatness, suppressing deterioration, and accurately positioning magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

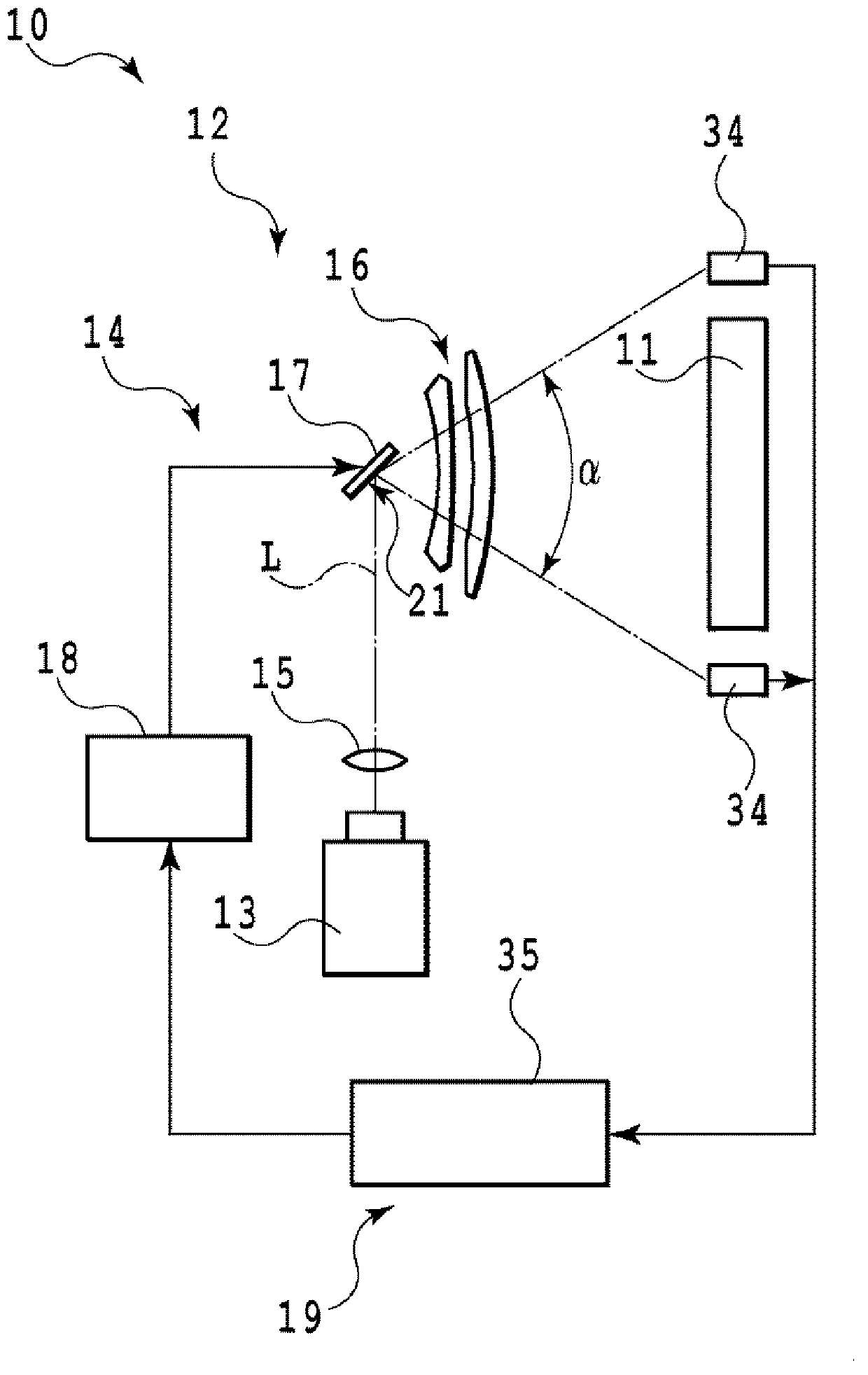

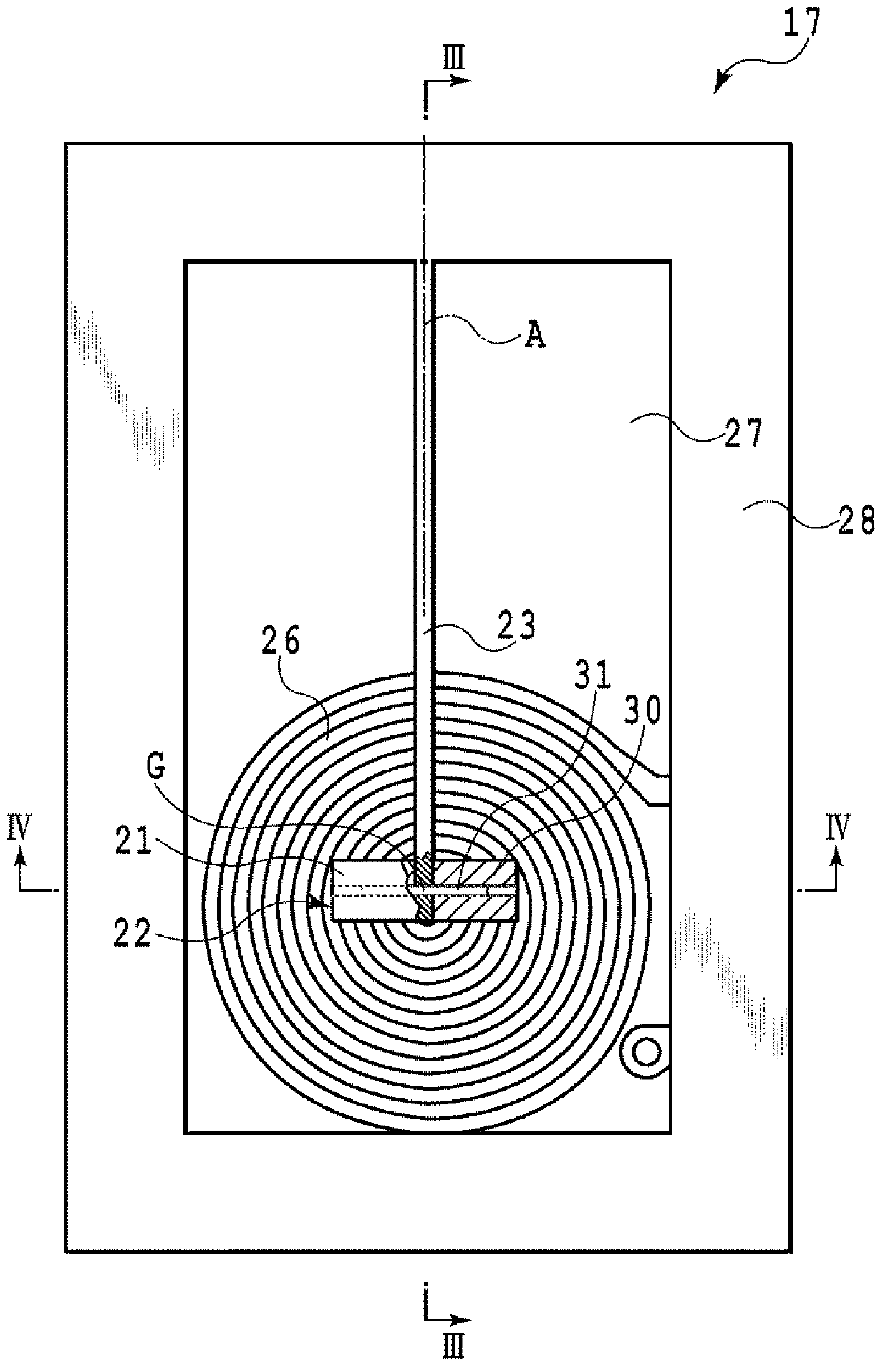

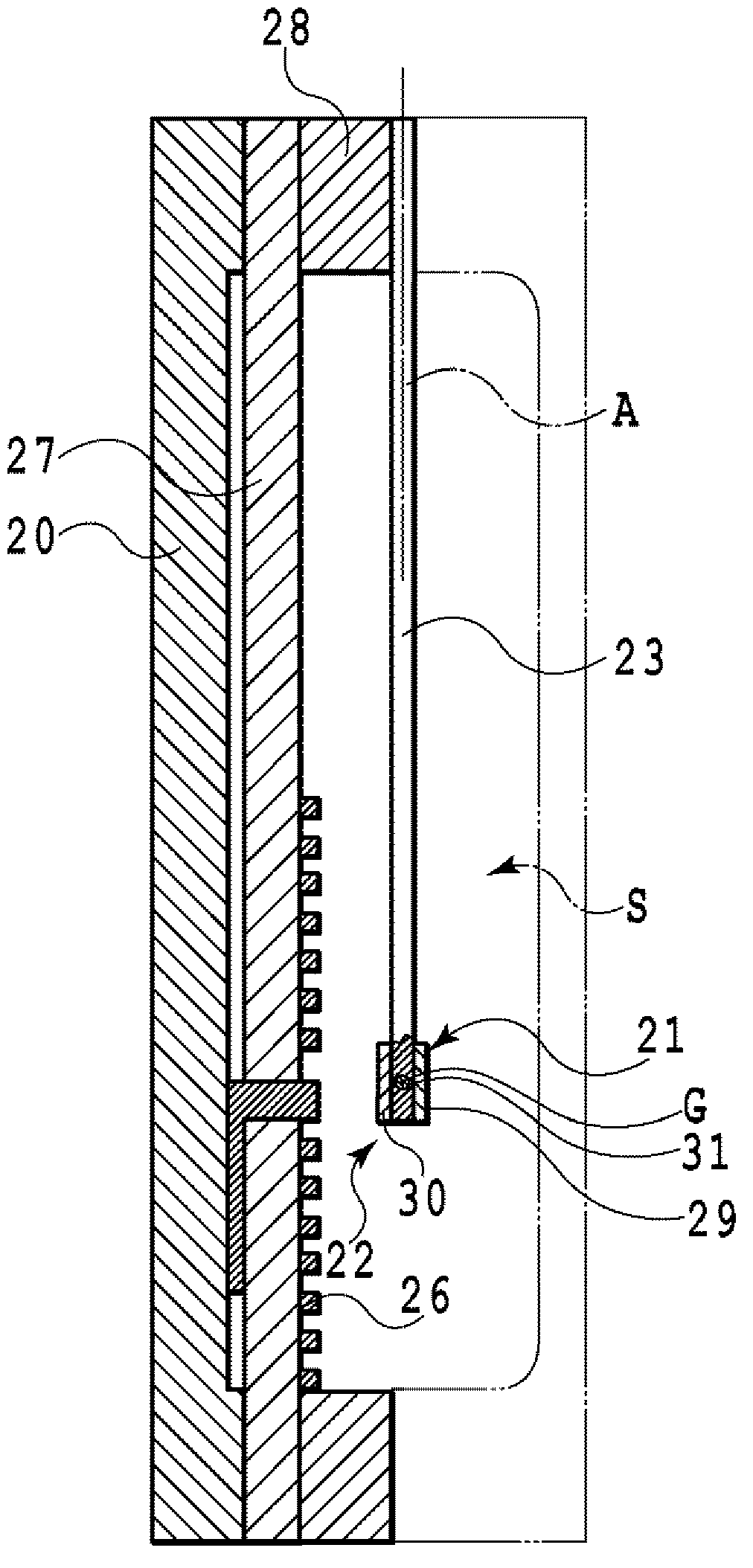

[0081] Below, refer to Figure 1 to Figure 10 An embodiment in which the image forming apparatus of the present invention is applied to a laser beam printer (hereinafter referred to as LBP) will be described in detail. However, it should be noted that the present invention is not limited to such embodiments, but can further combine the structures of different embodiments or appropriately adopt other arbitrary structures described in the claims and belonging to the technical gist of the present invention as required. structure.

[0082] The exposure part of the LBP of this embodiment is schematically shown in figure 1 In , the main part of the vibrating element in the optical scanning device of the LBP is extracted and shown in figure 2 in, will figure 2 The shape of the III-III cross-section in image 3 in, will figure 2 The enlarged cross-sectional shape of IV-IV in Figure 4 middle. And, the main part of the vibrating element is shown in the disassembled state in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com