A magnetic core-shell microsphere and its preparation method and application

A core-shell microsphere and magnetic technology, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of dye wastewater monitoring application that have not been reported, and achieve low production cost and high treatment efficiency. The effect of short time, safe and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

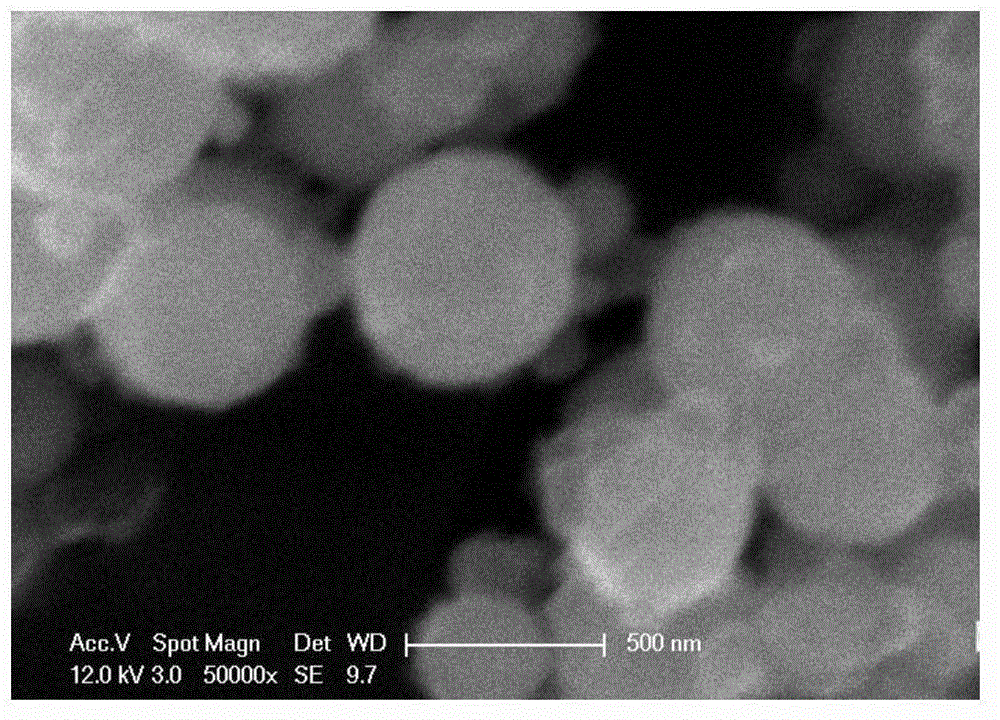

Embodiment 1

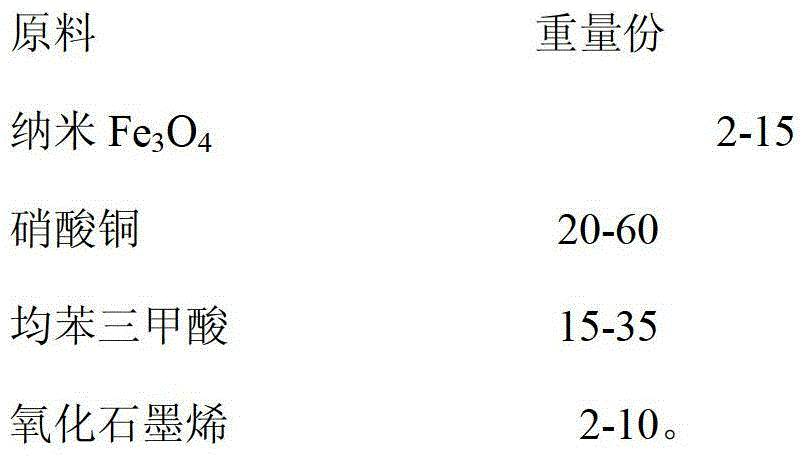

[0039] A novel magnetic core-shell microsphere for treating dye wastewater, which is made of the following raw materials in parts by weight:

[0040]

[0041] A preparation method for treating different concentrations of dye wastewater adsorbents, the steps are:

[0042] a) Weigh trimesic acid, copper nitrate, and graphene oxide raw materials in parts by weight, weigh 0.5302g trimesic acid, dissolve in 15mL absolute ethanol, and obtain solution A; weigh 1.0898g copper nitrate, dissolve in In 15mL of water, obtain a copper nitrate solution, then weigh 0.16g of graphene oxide, put it into the copper nitrate solution, and ultrasonically disperse the graphite oxide in the solution to obtain solution B; put solution A and solution B in a 50mL reaction kettle, Add 0.1g nano Fe 3 o 4 , the reaction temperature is 170 or 175 or 178 or 180 or 185°C;

[0043] b) Using temperature programming (that is, setting a certain heating rate), the heating rate is 4 or 5 or 6 °C / min, after t...

Embodiment 2-6

[0051] Embodiment 2-6 (weight part)

[0052]

[0053] Its preparation method is identical with embodiment 1.

Embodiment 7

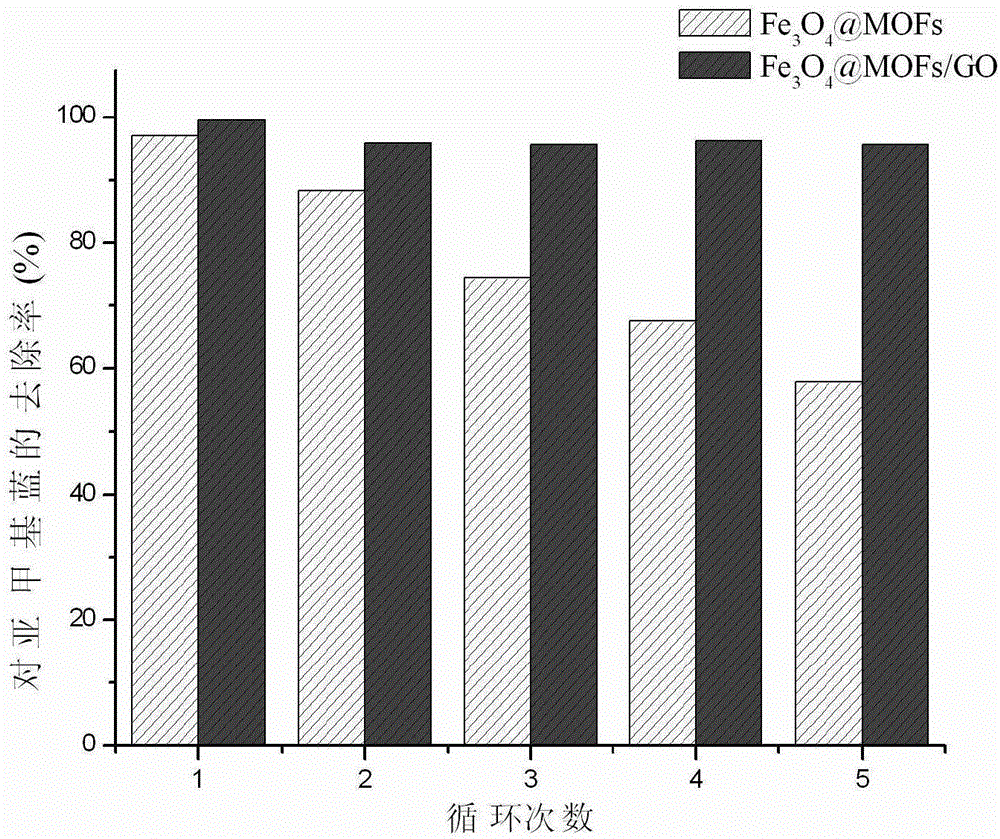

[0055] Methylene blue was used to simulate dye wastewater, and the concentration of methylene blue was 3.6mg / L. Add 0.1g Fe to 100mL dye wastewater 3 o 4 MOFs / GO (dosing concentration is 1.0g / L), after shaking for 20min, let it stand still, take the supernatant clear night to measure its absorbance, the concentration of residual methylene blue can be calculated through the relationship between absorbance and concentration, and p-methylene blue can be calculated from this The removal rate is 99.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com