A multi-layer wide grading sieve

A grading sieve and wide-width technology, which is applied in the direction of sieving, solid separation, and separating solids from solids with airflow, can solve the problem that grading sieve products are difficult to meet the screening efficiency, and achieve shortening of flow time and material Uniform screening and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

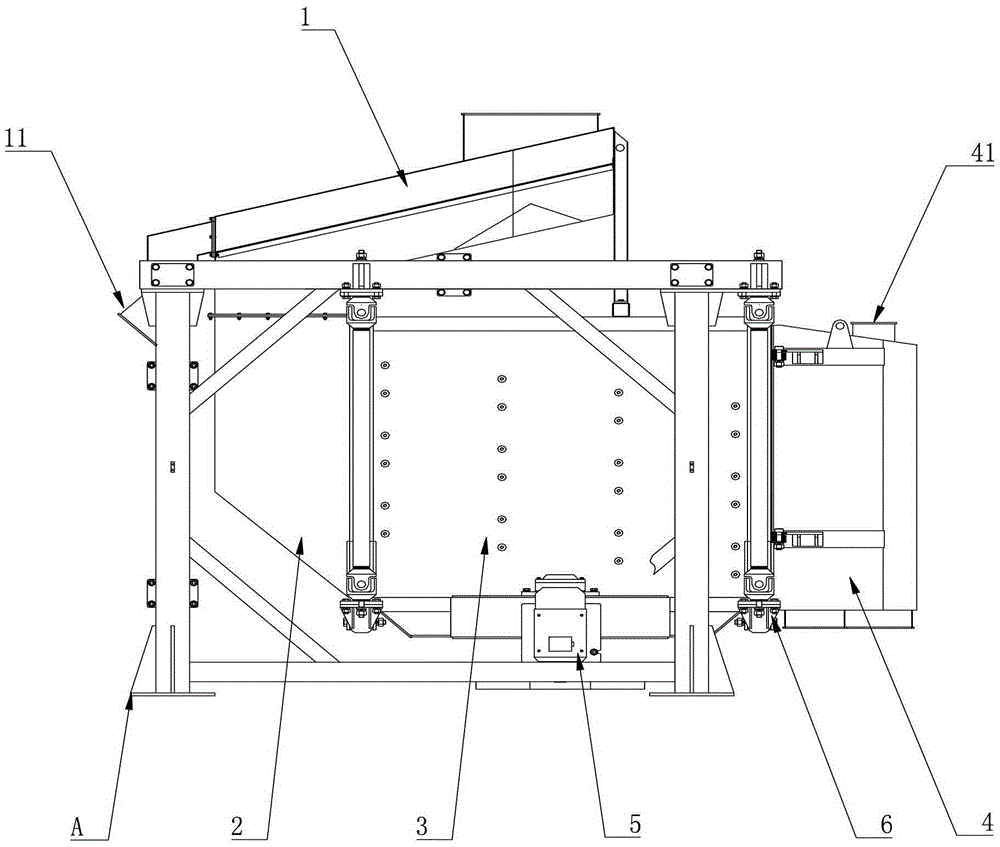

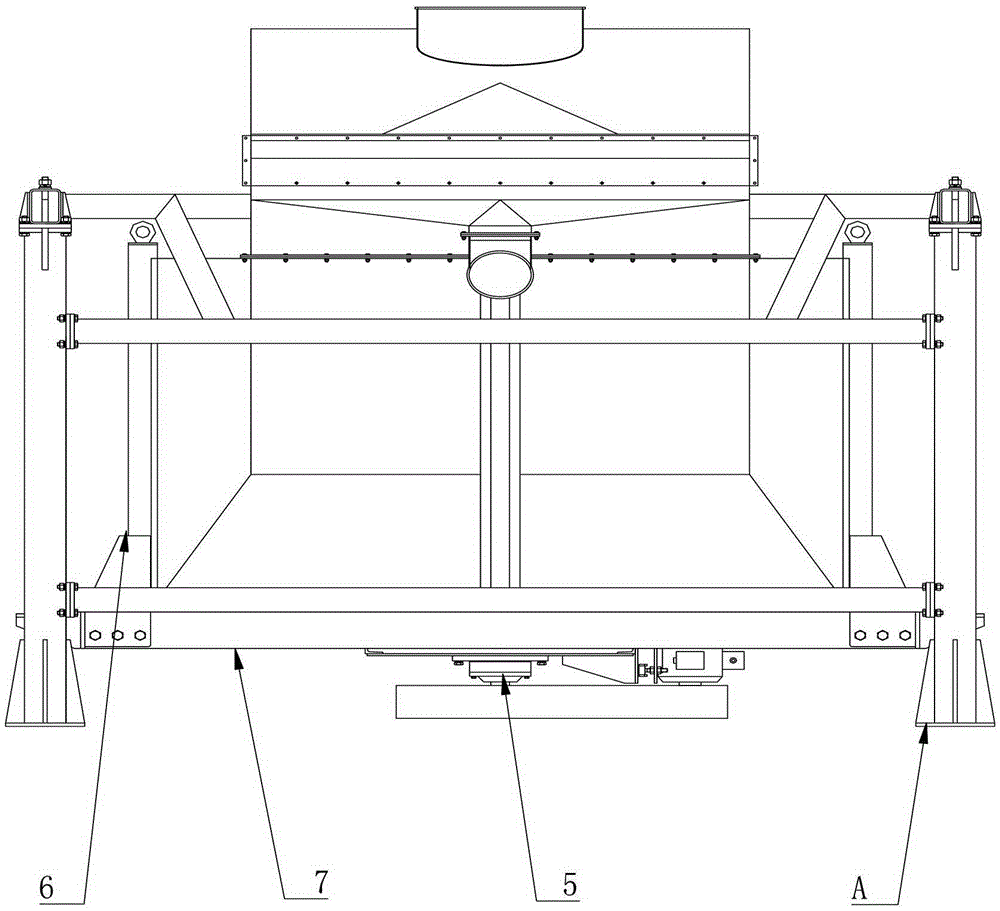

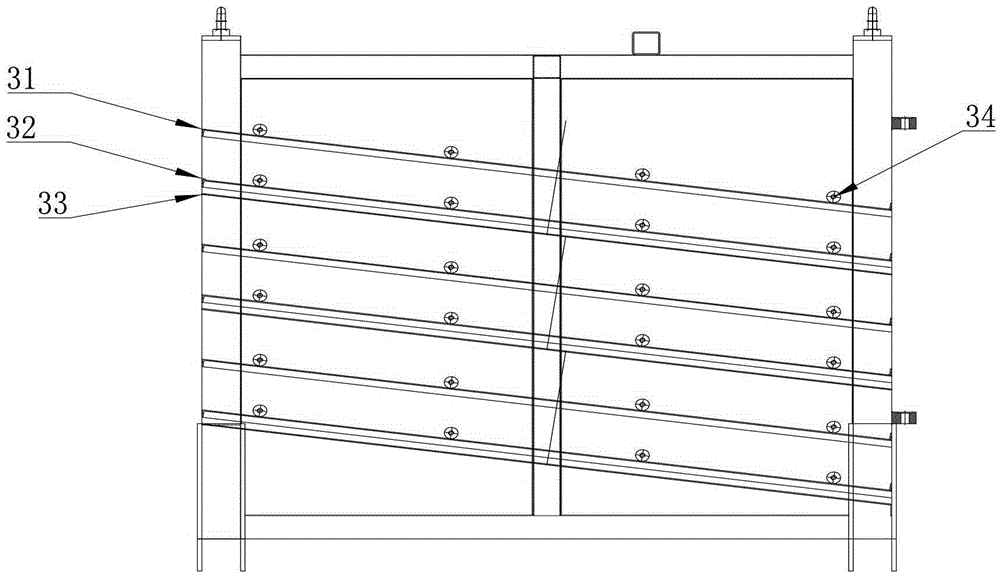

[0021] as attached Figure 1-4 As shown, the multi-layer wide-width grading screen of the present invention includes frame A, feed box 1 and two sets of screening systems located at the bottom of feed box 1, and each cover of screening system includes distribution box 2, screen box 3 And the discharge box 4, the distribution box 2, the screen box 3 and the discharge box 4 are arranged side by side below the feed box 1 in the lateral direction, and the entrance of the distribution box 2 and the outlet of the feed box 1 11 connected. Wherein, in this embodiment, the frame A adopts a square structure composed of four uprights and four crossbars, so that the force borne by the entire frame A can be evenly distributed to the four uprights in contact with the ground, Thereby increasing the stability of rack A in the screening process. Both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com