Resistance spot welding process capable of eliminating welding nugget hole shrinkage defect of cold-rolling dual-phase steel plate

A technology of resistance spot welding and dual-phase steel, which is applied in resistance welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as brittle fracture, shrinkage cavity defects, and decrease in weld nugget strength, and achieve a good joint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

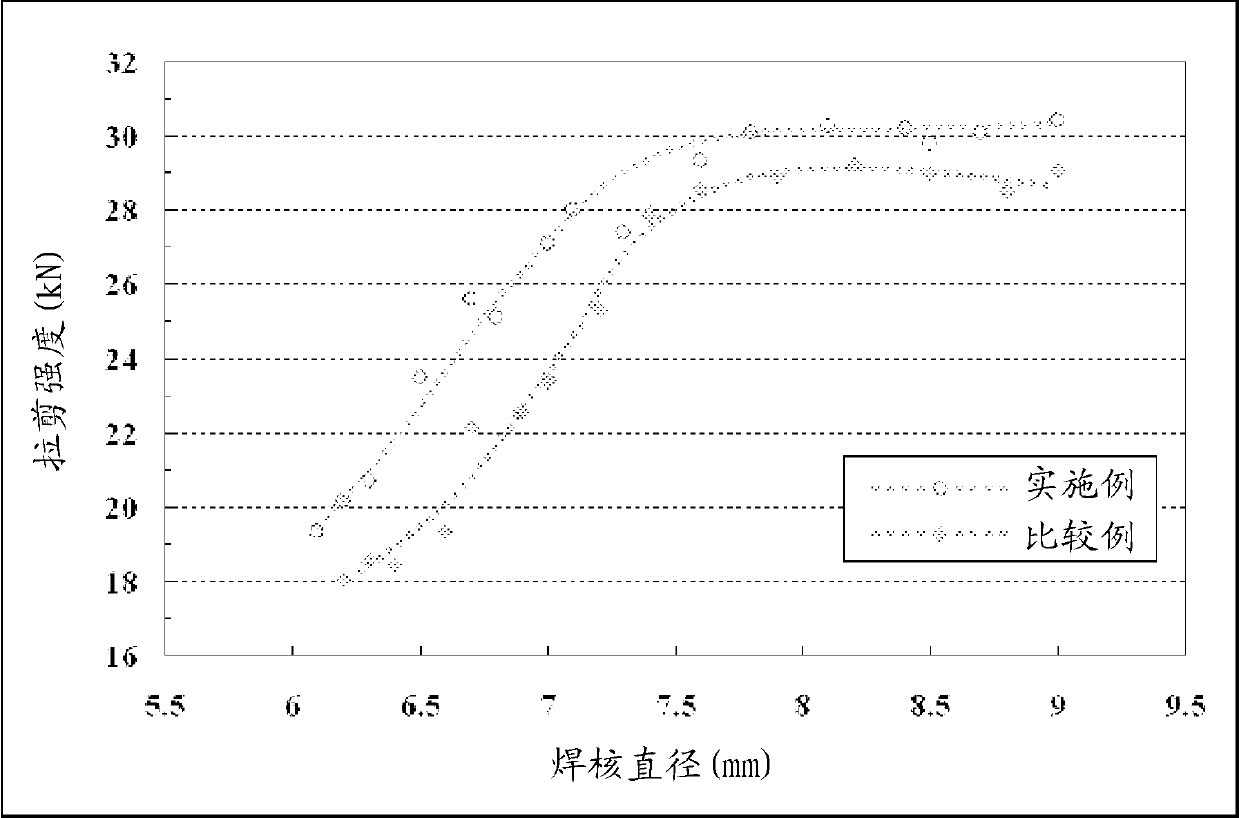

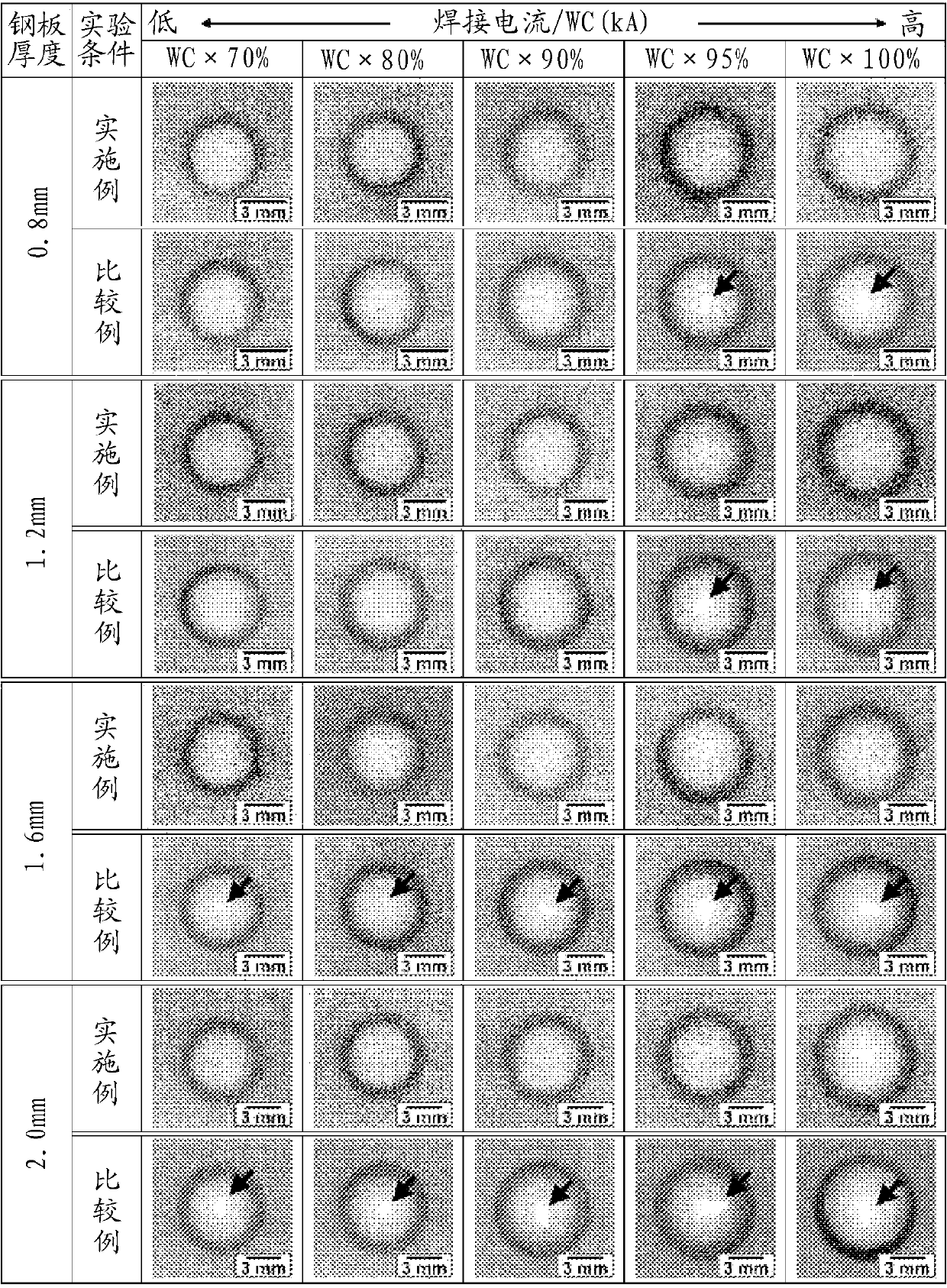

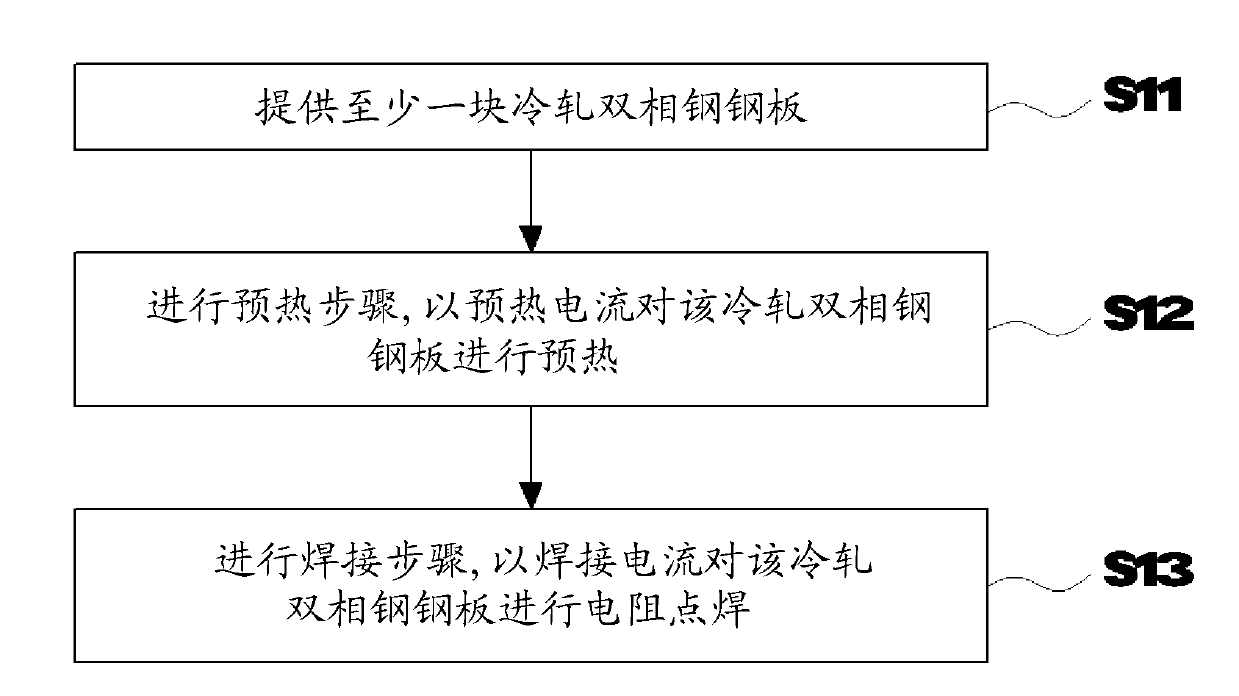

[0012] figure 1 The resistance spot welding process flow chart showing that the present invention can eliminate the weld nugget shrinkage cavity defect of cold-rolled dual-phase steel plate. see figure 1 In step S11, at least one cold-rolled dual-phase steel plate is provided, and the cold-rolled dual-phase steel plate has a thickness t. In this embodiment, the thickness t of the cold-rolled dual-phase steel plate is between 0.6 mm and 2.5 mm, and the carbon equivalent of the cold-rolled dual-phase steel plate (Ceq=C+Si / 30+Mn / 20+ 2P+4S) ranges from 0.18 weight percent (wt%) to 0.28 weight percent (wt%).

[0013] figure 2 It shows the time-current relationship curve diagram of the two-stage spot welding process of preheating and welding in the present invention. Please refer to figure 1 Step S12 of and figure 2 , carry out the preheating step, preheat the cold-rolled dual-phase steel plate with the preheating current PC, the calculation formula of the preheating current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap