Self-cleaning structure and manufacturing method thereof

A self-cleaning, structural layer technology, applied in the field of material processing, can solve problems that affect product quality and life, and cannot guarantee the fixing effect of nanoparticles, so as to achieve the effect of ensuring quality and life and increasing self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

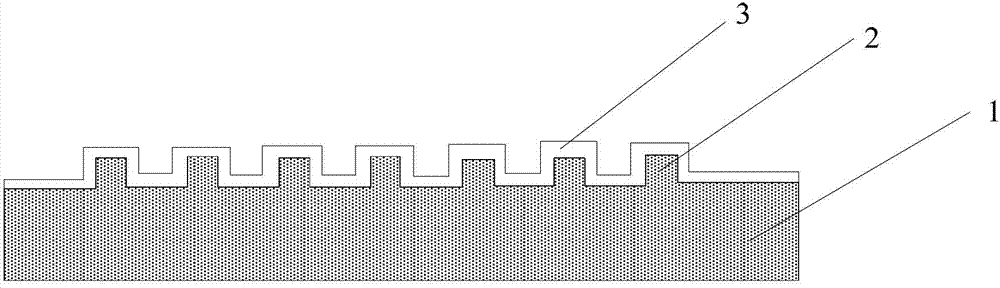

[0041] see figure 1 As mentioned above, the self-cleaning structure of the present invention includes a substrate 1 on which a patterned structural layer 2 is formed, and a layer of hydrophobic coating 3 is coated on the patterned structural layer 2 . The substrate 1 can be a glass substrate, a ceramic substrate, a metal substrate, a plastic substrate or a glazed substrate, or an enamel substrate; the hydrophobic coating 3 can be a fluorosilane coating, and the thickness of the hydrophobic coating 3 is less than or equal to 100nm . The patterned structural layer 2 is a matrix of protrusions formed on the surface of the substrate 1, the protrusions are triangular prisms, quadrangular prisms, polygonal prisms, cylinders, elliptical prisms, hemispheres or frustums, and the height of the protrusions is greater than or equal to 500nm.

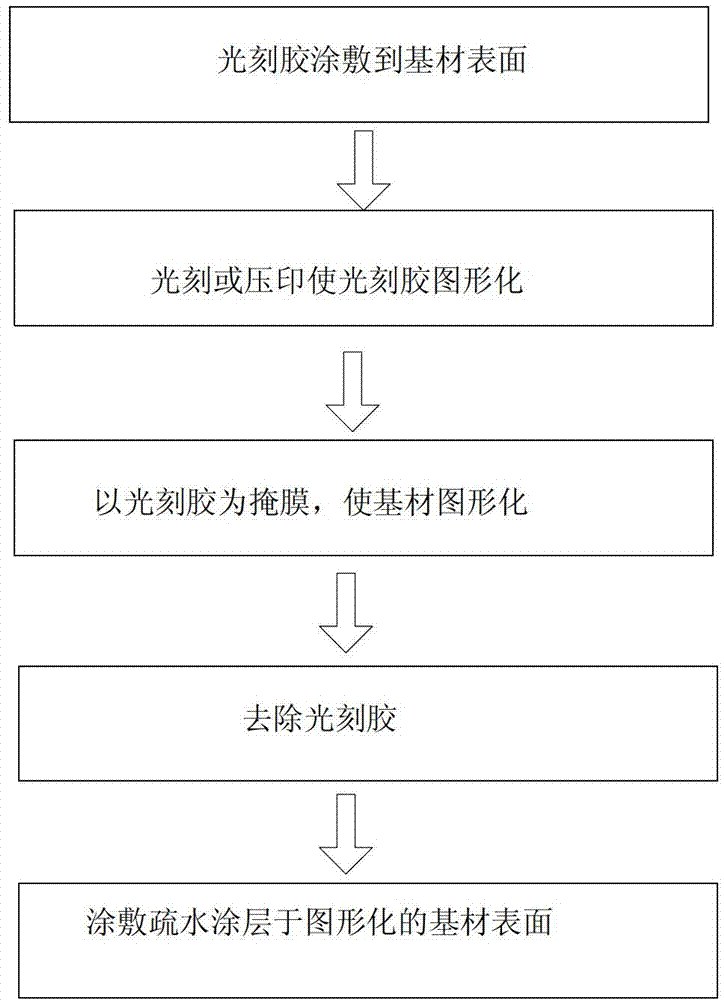

[0042] The manufacturing method of the self-cleaning structure of the present invention comprises the following steps:

[0043] (1) Apply a liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com