Mildew-proof flame-retardant wallpaper and preparation method thereof

A flame retardant, wallpaper technology, applied in the field of wallpaper, can solve the problems of easy water absorption, decline in the flame retardant performance of wallpaper, and no mildew resistance, and achieve the effects of enhancing antibacterial ability, enhancing environmental protection, and enhancing self-cleaning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

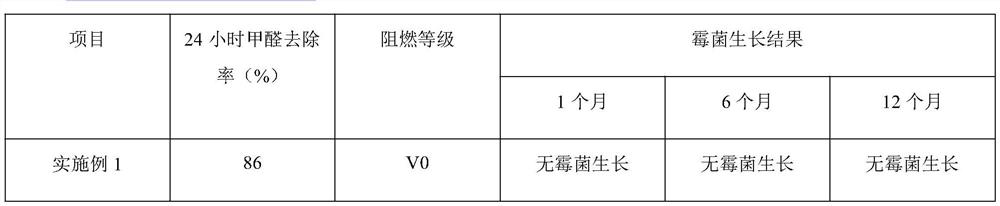

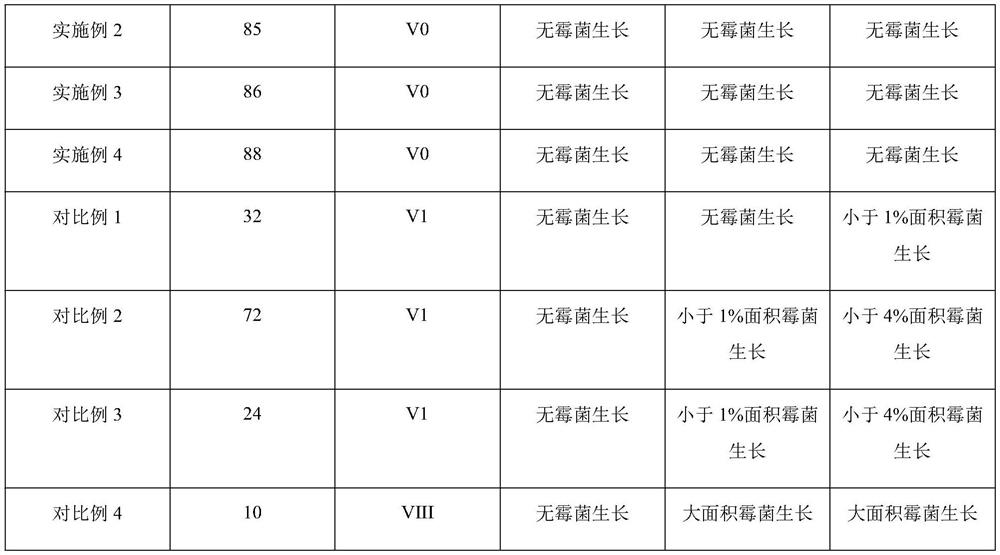

Examples

Embodiment 1

[0029] S1. Form an ink layer on the surface of one side of the wood pulp paper layer with a printing process to obtain a semi-finished wallpaper, wherein the thickness of the wood pulp paper layer is 1 mm, and the thickness of the ink layer is 0.3 mm;

[0030] S2. Preparation of flame retardant layer coating

[0031] Add 50 parts of deionized water and 25 parts of acrylic resin into the reaction kettle, turn on the mixer, stir and mix at a frequency of 300rpm for 20min, after mixing evenly, add 2 parts of phosphate salt type dispersant, 5 parts of antimony dioxide Flame retardant and 20 parts of modified manganese oxide colloids are dispersed by ultrasonic waves with a frequency of 25KHz for 20 minutes, then 1 part of hydroxymethyl cellulose thickener is added to the interior, and after stirring for 20 minutes, the flame retardant coating can be obtained .

[0032] Wherein the preparation steps of the modified manganese oxide colloid are: place the birnessite in a ball mill a...

Embodiment 2

[0039] S1. Form an ink layer on one side of the wood pulp paper layer by printing process to obtain a semi-finished wallpaper, wherein the thickness of the wood pulp paper layer is 1mm, and the thickness of the ink layer is 0.3mm

[0040] S2. Preparation of flame retardant layer coating

[0041] Add 70 parts of deionized water and 20 parts of acrylic resin into the reaction kettle, turn on the mixer, stir and mix at a frequency of 300rpm for 20min, after mixing evenly, add 1.5 parts of phosphate salt type dispersant, 10 parts of antimony dioxide After the flame retardant and 30 parts of modified manganese oxide colloids are dispersed by ultrasonic waves with a frequency of 25KHz for 20 minutes, 1 part of hydroxymethyl cellulose thickener is added to the interior, and after stirring for 20 minutes, the flame retardant coating can be obtained .

[0042] Wherein the preparation steps of the modified manganese oxide colloid are: place the birnessite in a ball mill and grind it un...

Embodiment 3

[0049] S1. Form an ink layer on the surface of one side of the wood pulp paper layer with a printing process to obtain a semi-finished wallpaper, wherein the thickness of the wood pulp paper layer is 1 mm, and the thickness of the ink layer is 0.3 mm;

[0050] S2. Preparation of flame retardant layer coating

[0051] Add 50 parts of deionized water and 25 parts of acrylic resin into the reaction kettle, turn on the mixer, stir and mix at a frequency of 300rpm for 20min, after mixing evenly, add 2 parts of phosphate salt type dispersant, 5 parts of antimony dioxide Flame retardant and 20 parts of modified manganese oxide colloids are dispersed by ultrasonic waves with a frequency of 25KHz for 20 minutes, then 1 part of hydroxymethyl cellulose thickener is added to the interior, and after stirring for 20 minutes, the flame retardant coating can be obtained .

[0052] Wherein the preparation steps of the modified manganese oxide colloid are: place the birnessite in a ball mill a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com