A self-supporting self-cleaning micro-nano through-hole filter membrane and its preparation method

A self-cleaning and self-supporting technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Cleansing effect, strong hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

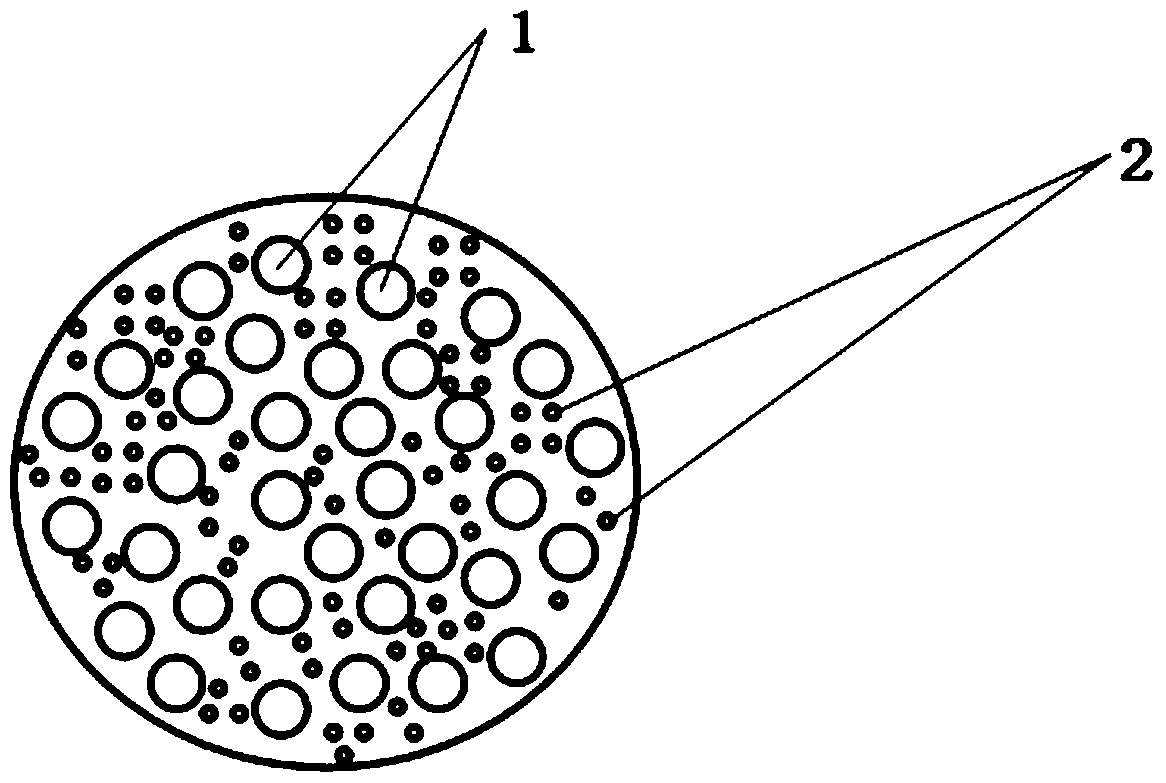

[0054] see figure 1 As shown, a self-supporting self-cleaning Wiener straight-through pore filter membrane of the present invention is processed by a die-casting process assisted by an electric field, and its preparation method comprises the following steps:

[0055] (1) Using a polished hard substrate (such as a commercially available polished copper sheet, silicon wafer, glass sheet) (or a flexible substrate (such as a commercially available polycarbonate film PC)), sputtering deposits a layer of conductive layer on its surface (such as metal chromium Cr layer, 50 nanometer thickness); 2 layer, 200 nm thick); if the polished hard substrate (such as commercially available polished copper sheet, highly doped conductive silicon sheet) (or flexible substrate (such as commercially available conductive polycarbonate film PC)) conducts itself, then It only needs to sputter a layer of insulating layer (such as silicon dioxide layer, 200 nanometers thick) on its surface;

[0056] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com