Bicycle expansion brake hub assembly

A bicycle and hub technology, applied in bicycle accessories, bicycle brakes, vehicle parts, etc., can solve problems such as poor shock resistance, poor braking performance, and low bearing capacity, and achieve overall firmness and reliability, good braking performance, and bearing capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

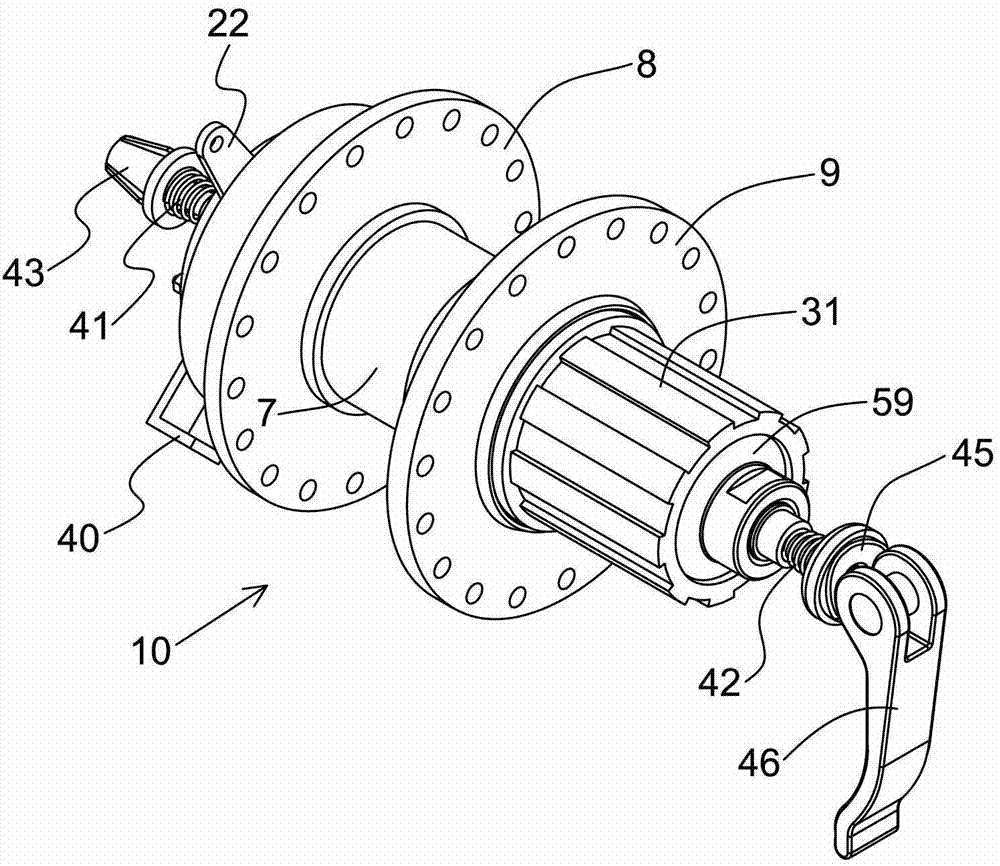

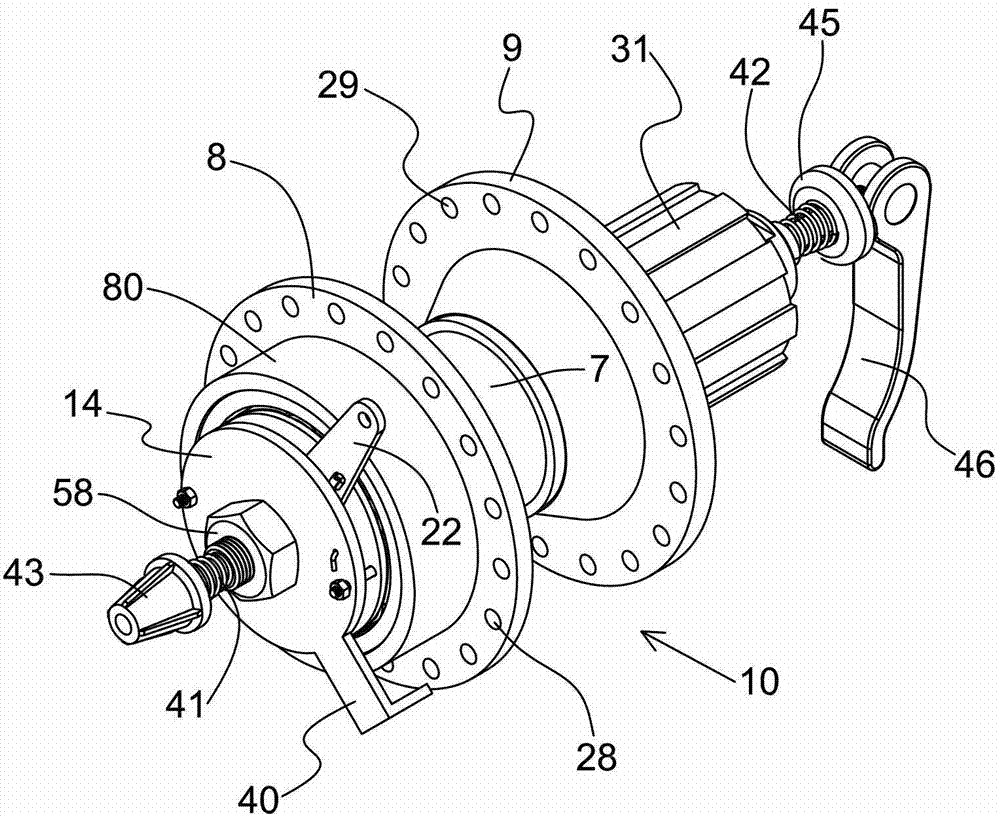

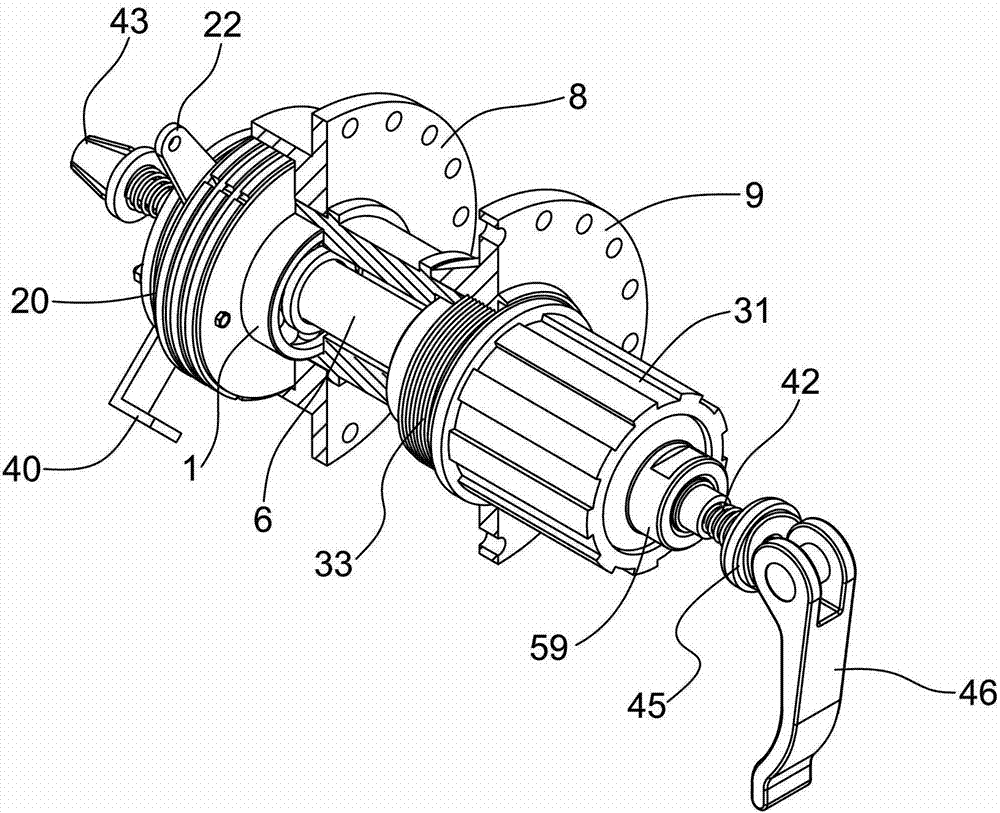

[0076] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , the present invention is a bicycle hub assembly, comprising a hub 10, a brake assembly 20, a flywheel assembly, a No. 1 bearing 1, a No. 2 bearing 2, and a center shaft 6. The flywheel assembly and the brake assembly are respectively arranged on the left side of the hub 10. , the right two ends, the hub 10 is composed of the axle skin 7, the left flower disk 8, and the right flower disk 9, the left flower disk 8 and the right flower disk 9 are respectively set on the left and right ends of the outer wall of the axle skin 7, the left flower disk 8 and the right flower disk 9 Piercing holes 28 and 29 are respectively arranged on the outer edge, and the shell 80 of the left faceplate 8 is cylindrical, and the No. 1 bearing 1 and the No. 2 bearing 2 a...

Embodiment 2

[0085] Please refer to Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , the structure of the brake assembly of this embodiment is the same as that of the above-mentioned embodiment 1, the difference lies in the flywheel assembly. , steel wire spring 65, No. 3 bearing 3, the tooth disc sleeve 61 and the right flower disc 9 are integrally formed, the ratchet ring 63 is fixed in the center hole of the tooth disc 62, and the tooth disc 62 can be a single-stage tooth disc or It is a multi-stage transmission chainring. The ratchet 64 is installed inside the ratchet ring 63. There are three ratchet grooves 66 on the outer circle of the ratchet 64, and a ratchet 67 is arranged in each ratchet groove 66. The ratchet 67 and the steel wire The spring 65 is connected, and the wire spring 65 is arranged around the outer circle of the ratchet 64 , and the ratchet 64 is encapsulated inside the ratchet ring 63 by the end cap 70 . The end cover ...

Embodiment 3

[0087] Please refer to Figure 27 , the structure of this embodiment is basically the same as that of the first embodiment above, the difference is that the assembly relationship of the rear hub is different. Shaft shoulders are provided, the left faceplate 8 is set on the left end of the shaft skin 7 through a tight fit, and the right face plate 9 is set on the right end of the shaft skin 7 through a tight fit. In this embodiment, the assembling relationship between the left faceplate 8 , the right faceplate 9 and the shaft skin 7 is threaded connection, and is fixed by metal glue. The left faceplate 8 is screwed to the left end of the shaft skin 7 through the internal thread thread 76, and fixed by metal glue, and the right faceplate 9 is screwed to the right end of the shaft skin 7 through the internal thread thread 77, and bonded by metal glue fixed. The model of the metal glue mentioned above is ZY-anaerobic glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com