A Mobile Platform Based on Air Cushion and Mecanum Wheel

A mobile platform, air cushion technology, applied in the direction of motor vehicles, transportation and packaging, can solve the problems of increased wheels, wear, easy wear, etc., to achieve the effects of reduced wear, stable and reliable fixation, and small steering space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below in conjunction with specific embodiments:

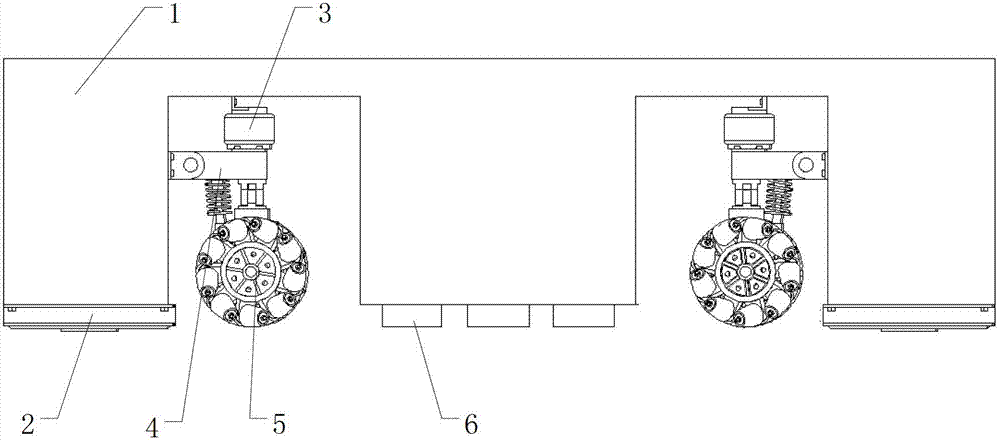

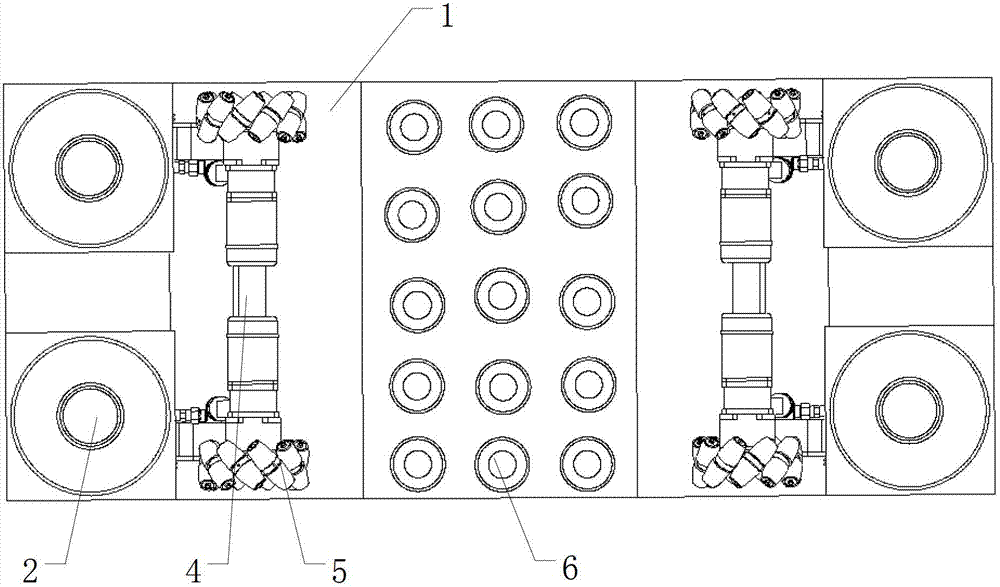

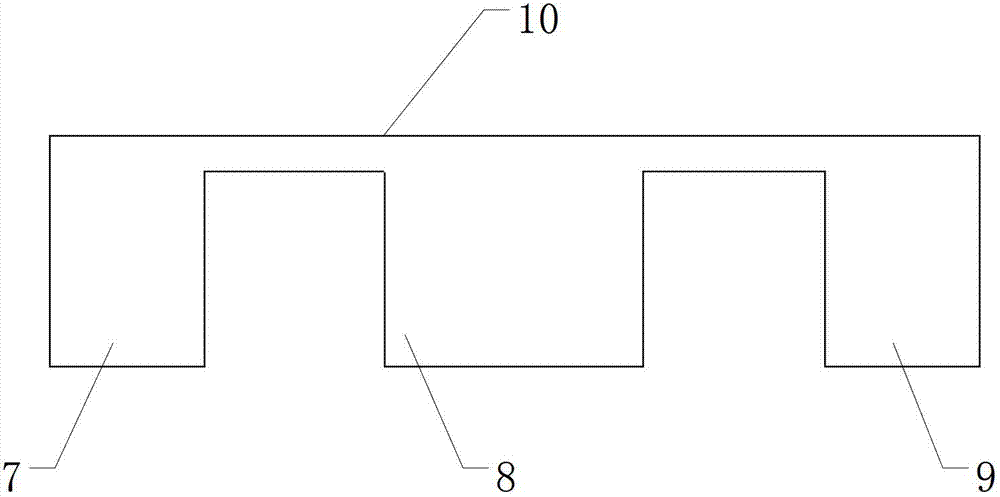

[0018] Reference attached figure 1 In this embodiment, the mobile platform based on air cushion and McCannham wheels is composed of a frame 1, an air cushion unit 2, an air spring 3, a swing arm suspension 4, a McCannham wheel 5 and an electromagnet 6. The overall structure is symmetrical from front to back and from left to right. Reference attached image 3 The frame is divided into a front frame 7, a middle frame 8 and a rear frame 9. The upper part of the front frame, the middle frame and the rear frame are connected by an upper supporting plate 10.

[0019] There are four air cushion units 2, which are fixedly connected to the frame, and are respectively installed on the two sides of the bottom of the front frame and the rear frame of the frame. The electromagnet 6 is evenly installed on the bottom of the middle frame.

[0020] A set of swing arm type suspensions are respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com