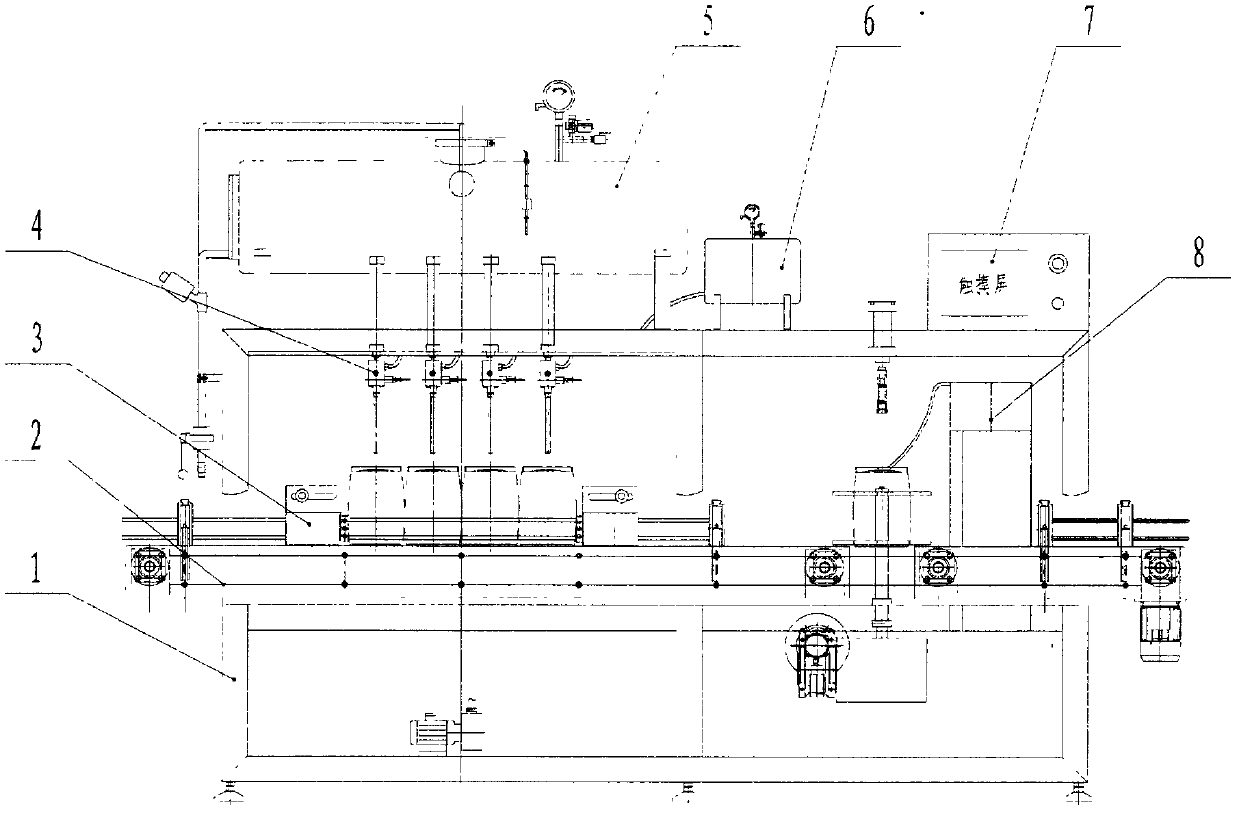

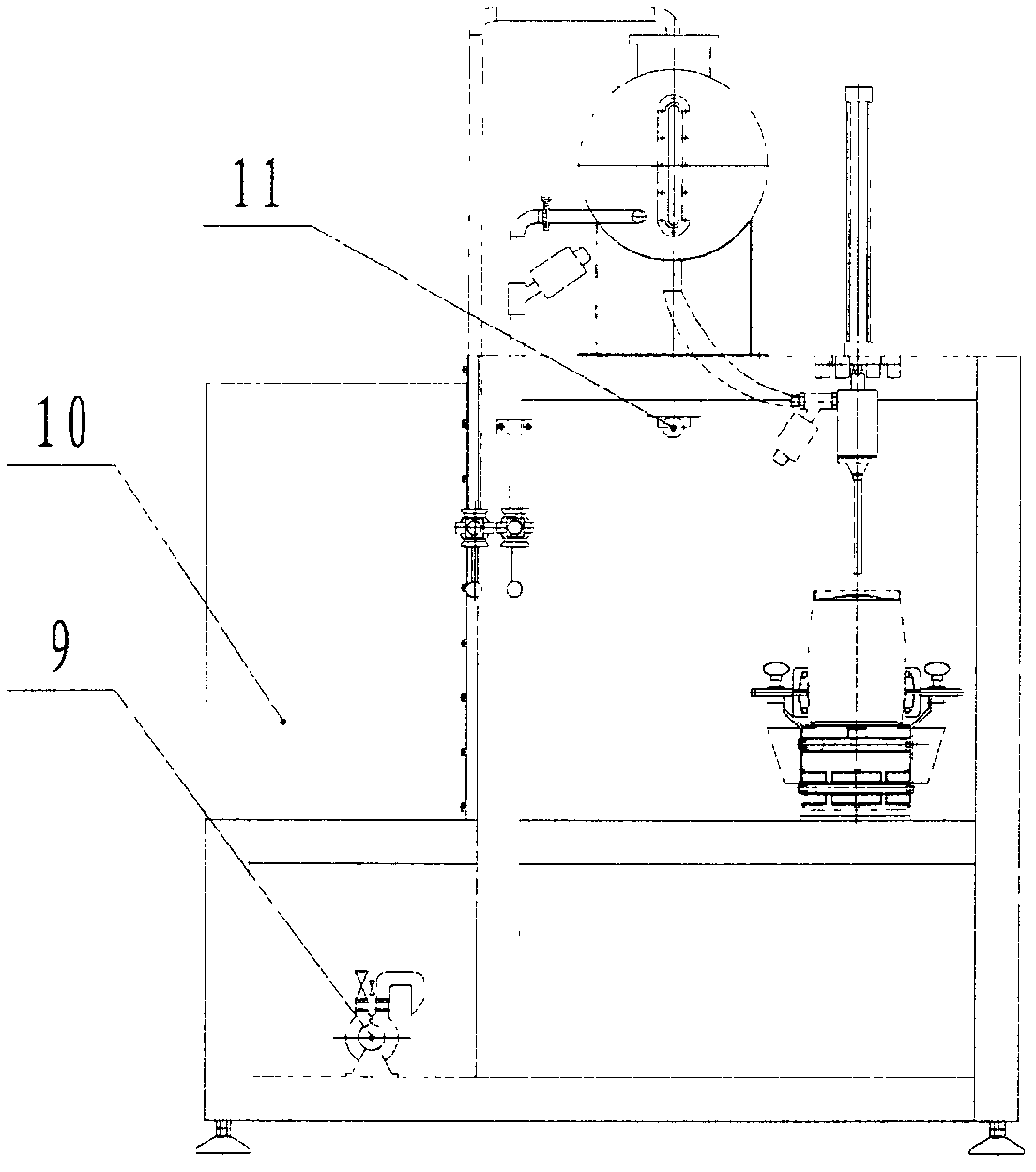

Full-automatic double-cylinder equal difference pressure asepsis filling and sealing machine

A fully automatic, filling and sealing machine technology, applied in bottling machines, bottle filling, packaging, etc., can solve the problems of high manufacturing cost, large floor space, pure draft beer pollution, etc., to avoid leakage and avoid secondary Pollution, effect of extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below with reference to the accompanying drawings.

[0013] The whole process is: turn on the power before filling, turn on the aseptic fan and ultraviolet germicidal lamp, sterilize the space for about 40 minutes, enter the wine or beverage into the wine storage tank, enter the air into the air storage tank, adjust the wine storage tank and the air storage tank The pressure of the filling container is transported to the aseptic filling space through the conveyor chain, and the position is detected by infrared rays. The barrel stop cylinder accurately limits the position of the filling container and the filling head, and the filling head is pressed down to vacuumize the container. , pressure preparation, filling, stabilization, pressure relief and other processes, the filling head is equipped with a photoelectric liquid level sensor, the wine will automatically stop when the wine is full, the filling head is lifted, the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com