Novel Portland slag P.SA32.5 cement

A P.SA32.5, silicate technology, applied in the new slag silicate P.SA32.5 cement, general portland cement field, can solve the strength, impermeability, water retention, corrosion resistance and resistance General abrasive performance and other problems, to achieve the effect of good water retention, eliminating pollution sources and reducing cement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

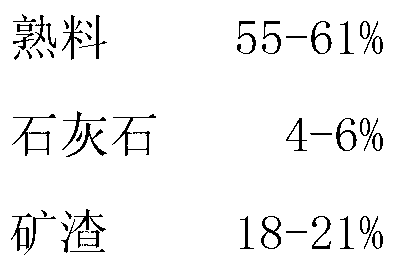

[0021] A novel slag Portland P.SA32.5 cement, its constituents and weight percentages are respectively:

[0022]

[0023] The above-mentioned various substances are mixed together according to the weight ratio, and evenly ground in a cement mill to become a finished product.

Embodiment 2

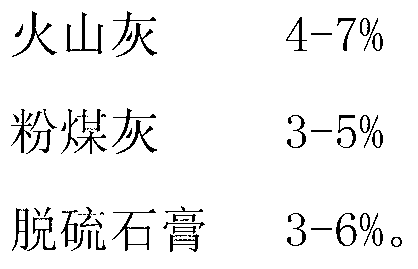

[0025] A novel slag Portland P.SA32.5 cement, its constituents and weight percentages are respectively:

[0026]

[0027] The above-mentioned various substances are mixed together according to the weight ratio, and evenly ground in a cement mill to become a finished product.

Embodiment 3

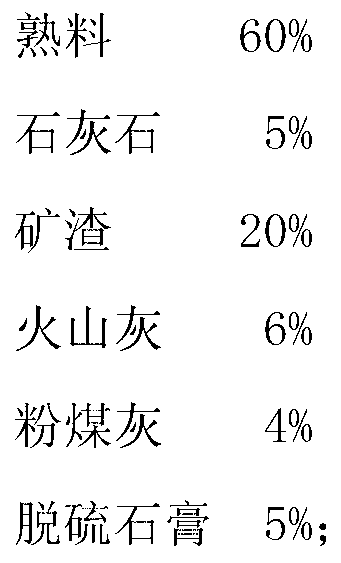

[0029] A novel slag Portland P.SA32.5 cement, its constituents and weight percentages are respectively:

[0030]

[0031] The above-mentioned various substances are mixed together according to the weight ratio, and evenly ground in a cement mill to become a finished product.

[0032] Experimental performance index of the present invention:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com