Corn-coated slow-release long-acting compound fertilizer with diatomite as carrier

A technology of coated slow-release and diatomite, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of few products and few slow-release long-acting fertilizers, and achieve low price, easy popularization and use, and improved The effect of fertilizer use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) First, use distilled water as the binder, put the nitrogen fertilizer and potassium fertilizer that can pass through the 80-mesh sieve in the above ratio and put them into a granulator for granulation. The basic parameters of the granulator are: the speed is 40 rpm, the temperature for 70 o C, the elevation angle is 50 0 ;

[0020] 2) Afterwards, spray about 50 ml of distilled water to moisten the surface of the granulated fertilizer so that the adhered diatomite can pass through a 100-mesh sieve;

[0021] 3) After the 10% diatomite wrapping granulation is completed, then use a high-pressure spray gun to evenly spray a small amount of polyvinyl alcohol, a coating curing material, onto the surface of the fertilizer granules;

[0022] 4) Finally, pour 3% rosin paraffin mixture (rosin: paraffin = 1:2) into the drum and keep the temperature at 70 oC , and wrap the coated fertilizer granules again after melting.

Embodiment 2

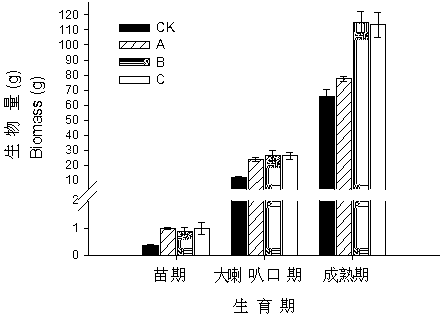

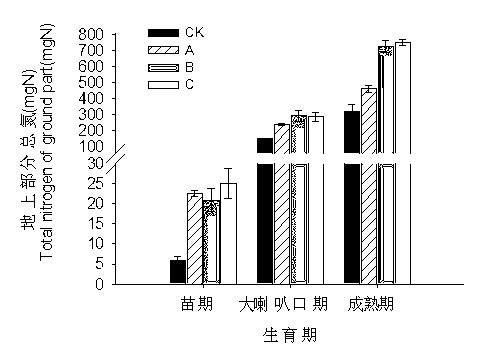

[0024] 1 Materials and methods

[0025] 1.1 Corn variety: Zhengdan 958, purchased from the market;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com