Resin adhesive free from formaldehyde release as well as preparation method and application thereof

A resin adhesive and formaldehyde release technology, applied in the polymer field, can solve the problems of difficulty, reduce the amount of formaldehyde released, and fail to meet the requirements of use, and achieve the effect of stable structure and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

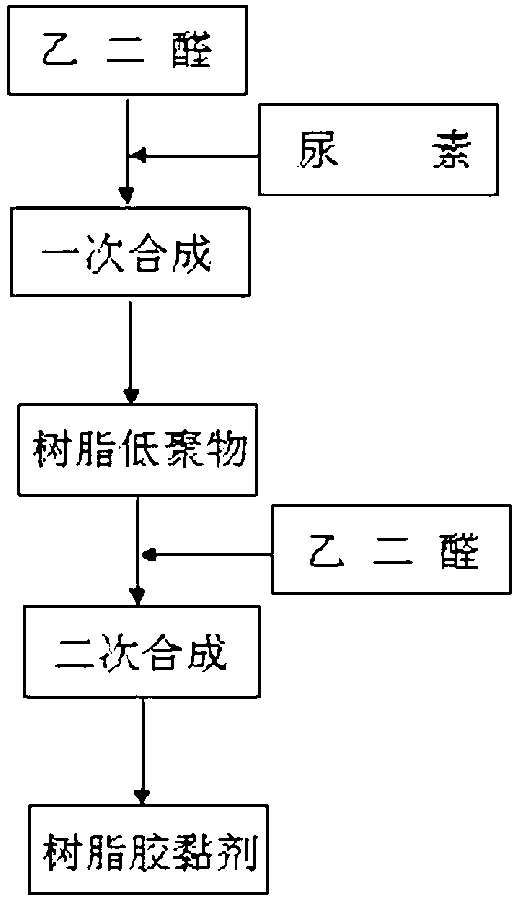

[0019] The preparation method of the formaldehyde-free resin adhesive of the present invention includes raw material preparation, primary synthesis, and secondary synthesis steps, specifically including:

[0020] A. Raw material preparation: Weigh respectively according to the molar ratio of raw material urea and glyoxal 1:1~2, and then divide the weighed glyoxal into two parts. The aldehyde molar ratio is 1:0.8~1 for weighing, and the rest is the second part of glyoxal;

[0021] B. One-time synthesis: adjust the pH value of the first part of glyoxal to 2~6 with a pH regulator, add the raw material urea while stirring, and react at 70~80°C for 90~120min to obtain the resin glyoxal-urea resin low Polymer;

[0022] C. Secondary synthesis: add the second part of glyoxal to the obtained resin glyoxal-urea resin oligomer, adjust the pH value to 3~8.5 with a pH regulator, and react at 70~80°C for 60~90min , to obtain the target product after cooling treatment.

[0023] The pH reg...

Embodiment 1

[0033] A. Weigh 2.0 moles of glyoxal for the first time, adjust the pH value to 3.0-4.0, add 2.3 moles of urea under stirring, and keep the reaction at 70°C for 120 minutes to obtain the resin glyoxal-urea resin oligomer (UG);

[0034] B. Add 1.3 moles of glyoxal for the second time, adjust the pH value between 3.0-4.0, keep the reaction at 75°C for 80 minutes, cool to below 40°C, adjust the pH to 7~8 and discharge to obtain urea-B Dialdehyde (UG) resin wood adhesive.

Embodiment 2

[0036] A. Weigh 2.0 moles of glyoxal for the first time, adjust the pH value at 3.0-4.0, add 2.5 moles of urea under stirring, and keep the reaction at 80°C for 90 minutes to obtain the resin glyoxal-urea resin oligomer (UG);

[0037] B. Add 0.5 moles of glyoxal for the second time, adjust the pH value between 3.0-4.0, keep the temperature at 70°C for 90 minutes, cool to below 40°C, adjust the pH to 7~8, and then discharge to obtain urea-B Dialdehyde (UG) resin wood adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com