Cross-linking agent composition, antigen fibrillating solution spinning cellulose fiber, and preparation methods thereof

A technology of cellulose fiber and cross-linking agent, which is applied in the field of fiber processing, can solve the problems of easy fibrillation of solution-spun cellulose fiber, and achieve the effect of improving the anti-fibrillation performance of fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

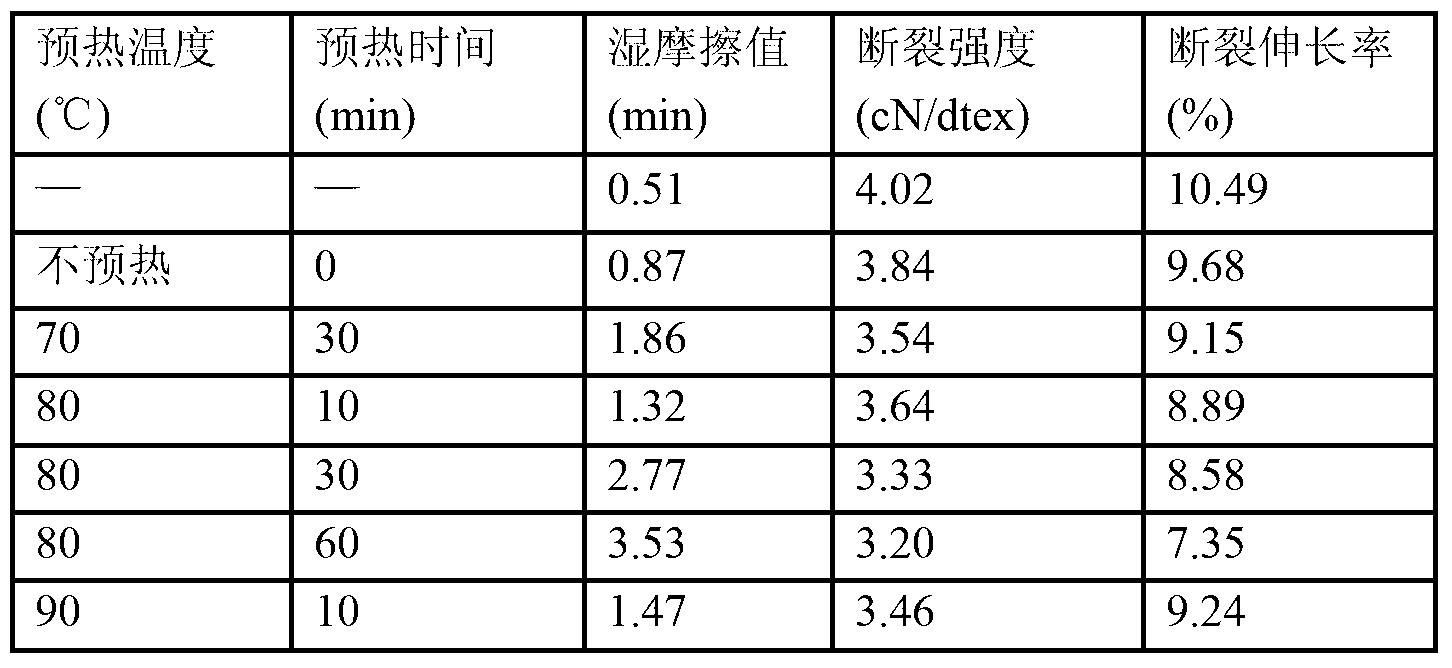

[0056] Dissolve PMA, CA, and SHP with a molecular weight of 600 in distilled water at a weight ratio of 2:5:3 at room temperature to obtain a crosslinking agent solution. The content of PMA in the crosslinking agent solution is 40g / L, and the content of CA is 100g / L, the content of SHP is 60g / L. Immerse the cellulose fibers in the above crosslinking agent solution, soak for 10 minutes to obtain mixed fibers, preheat the mixed fibers, and control the preheating temperature at 70, 80, and 90°C respectively, and then heat the mixed fibers at 170°C for 8 minutes. Wash and dry. The wet friction values and mechanical properties of the obtained fibers are listed in Table 1.

[0057] Table 1

[0058]

[0059] It can be known from the content in Table 1 that the post-crosslinking treatment of cellulose fibers by using the crosslinking agent composition provided by the present invention can effectively improve the anti-fibrillation performance of the fibers. Especially in the p...

Embodiment 2

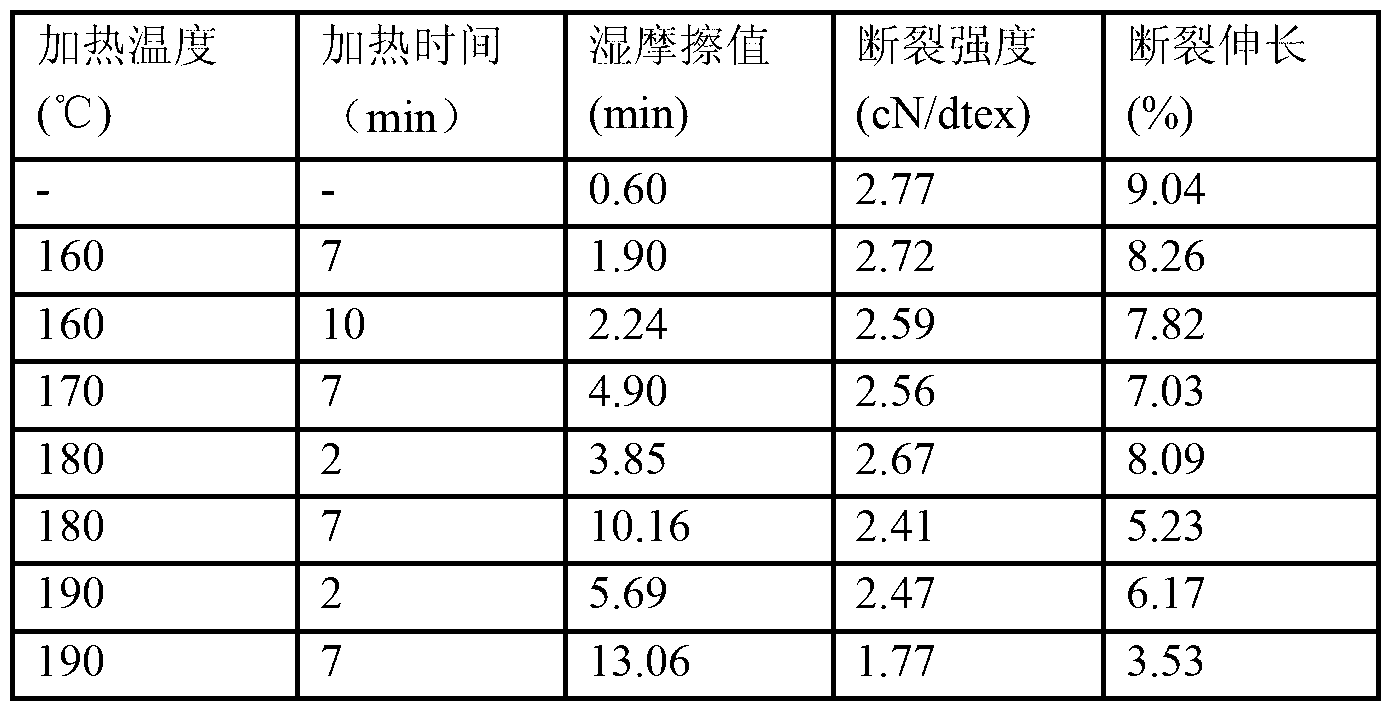

[0061] Dissolve PMA, CA, and SHP with a molecular weight of 600 in distilled water at a weight ratio of 2:5:3 at room temperature to obtain a crosslinking agent solution. The content of PMA in the crosslinking agent solution is 40g / L, and the content of CA is 100g / L, the content of SHP is 60g / L. Dip the cellulose fibers into the above crosslinking agent solution for 10 minutes, then preheat the fibers at 80°C for 60 minutes, and then heat the fibers at 160°C, 170°C, 180°C, and 190°C for a certain period of time. Wash and dry. The wet friction values and mechanical properties of the obtained fiber bundles are listed in Table 2.

[0062] Table 2

[0063]

[0064] As can be seen from the content in Table 2, under the condition that other conditions are determined, the increase of heating time and temperature in the crosslinking post-treatment of cellulose fibers using the crosslinking agent composition provided by the present invention is beneficial to improve the wet fri...

Embodiment 3

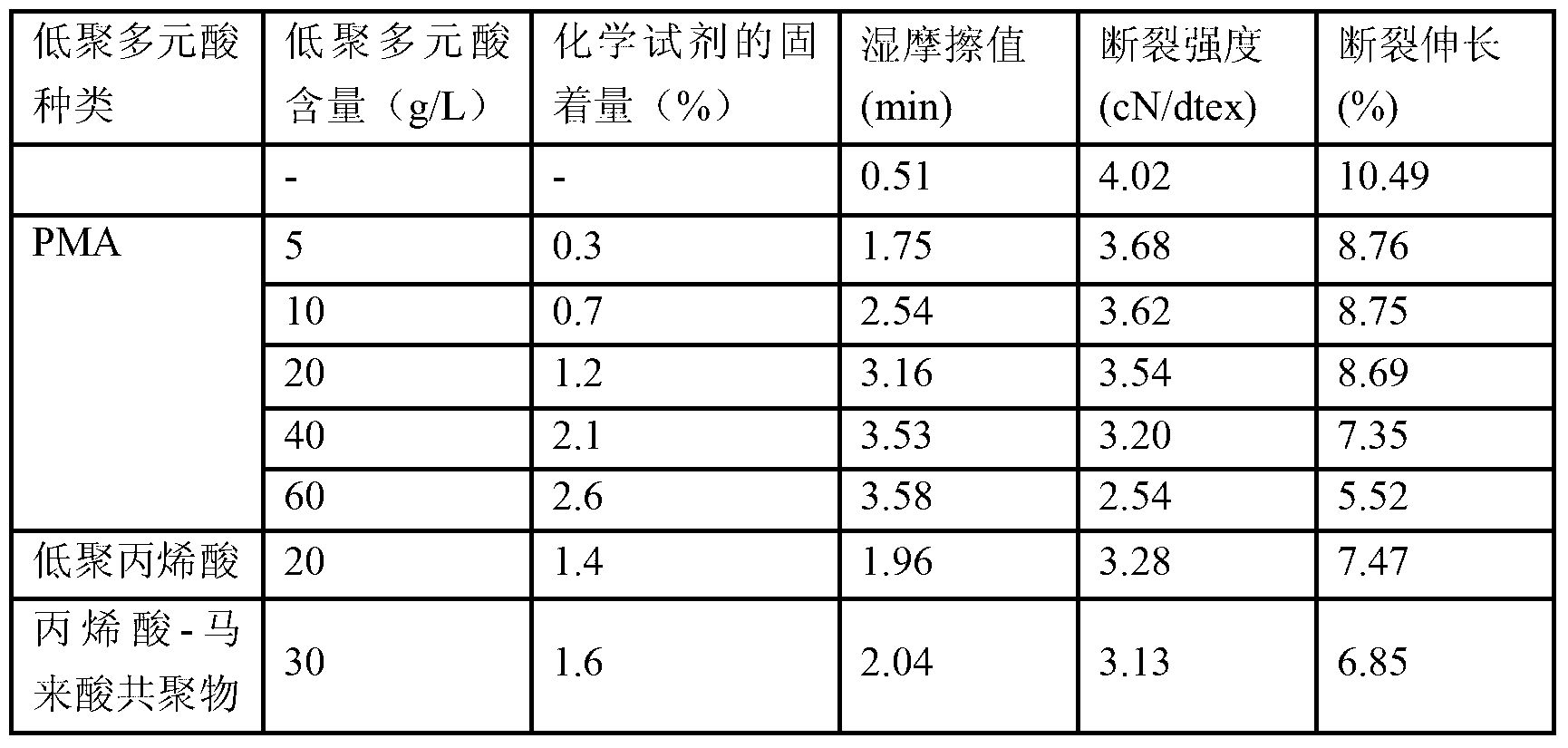

[0068] Dissolving oligomeric polybasic acid, CA and SHP with a molecular weight of 600 in distilled water at normal temperature to obtain a crosslinking agent solution, the content of oligomeric polybasic acid in the crosslinking agent solution is 5-60g / L, and the content of CA is 100g / L, the content of SHP is 60g / L. Dip the cellulose fibers into the above crosslinking agent solution for 10 minutes to obtain mixed fibers, then preheat the mixed fibers at 80°C for 60 minutes, then heat the fibers at 170°C for 8 minutes, wash and dry. The obtained fiber wet friction value, mechanical properties and fixation amount of chemical reagents on the fiber are listed in Table 3.

[0069] table 3

[0070]

[0071] It can be seen from the content in Table 3 that in the crosslinking agent composition of the present invention, the content of PMA has a significant impact on the fibrosis performance of fibrin. The higher the content of PMA, the higher the wet friction value of the fiber,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com