Special rotating joint for ultra-low-temperature fluid loading and unloading arm

A technology of fluid loading and unloading arms and rotary joints, which is applied to equipment loaded into pressure vessels, gas/liquid distribution and storage, methods of container discharge, etc., which can solve hidden dangers in production safety, leakage during use, and unsatisfactory compensation Status and other issues, to achieve the effect of guaranteed reliability, excellent compensation, and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

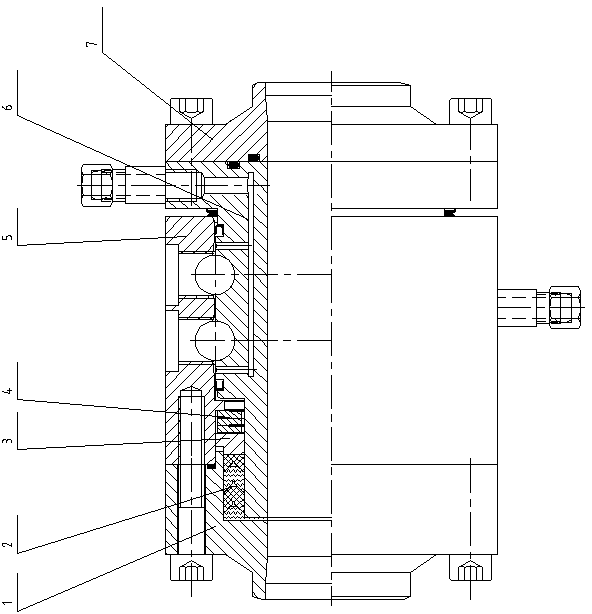

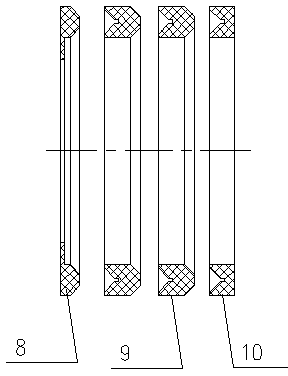

[0008] A special rotary joint for an ultra-low temperature fluid loading and unloading arm, comprising an inner ring 6 and an outer ring 5. A steel ball raceway is arranged between the inner ring and the outer ring. The steel ball raceway is equipped with steel balls. The left end of the outer ring 5 is connected to the outer ring. The ring flange 1 is connected, the right end of the inner ring 6 is connected with the inner ring flange 7, and the steel ball raceway between the inner ring and the outer ring is equipped with a nitrogen circulating purge mechanism. The outer ring and the outer ring flange are tightened by bolts. The outer ring flange 1 is provided with a cylinder that faces the left end of the outer ring 5. The main sealing ring 2 is installed between the inner wall of the cylinder and the outer wall of the inner ring. A butterfly spring 4 for pressing the main sealing ring is arranged between the outer walls of the ring, and a pressing ring 3 is arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com