Pressure bearing detection device and method of one-way valve

A detection device and one-way valve technology, applied in the field of pressure-bearing devices, can solve the problems of heavy weight, cumbersome, slow detection process, etc., and achieve the effects of reducing detection costs, ensuring the pass rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

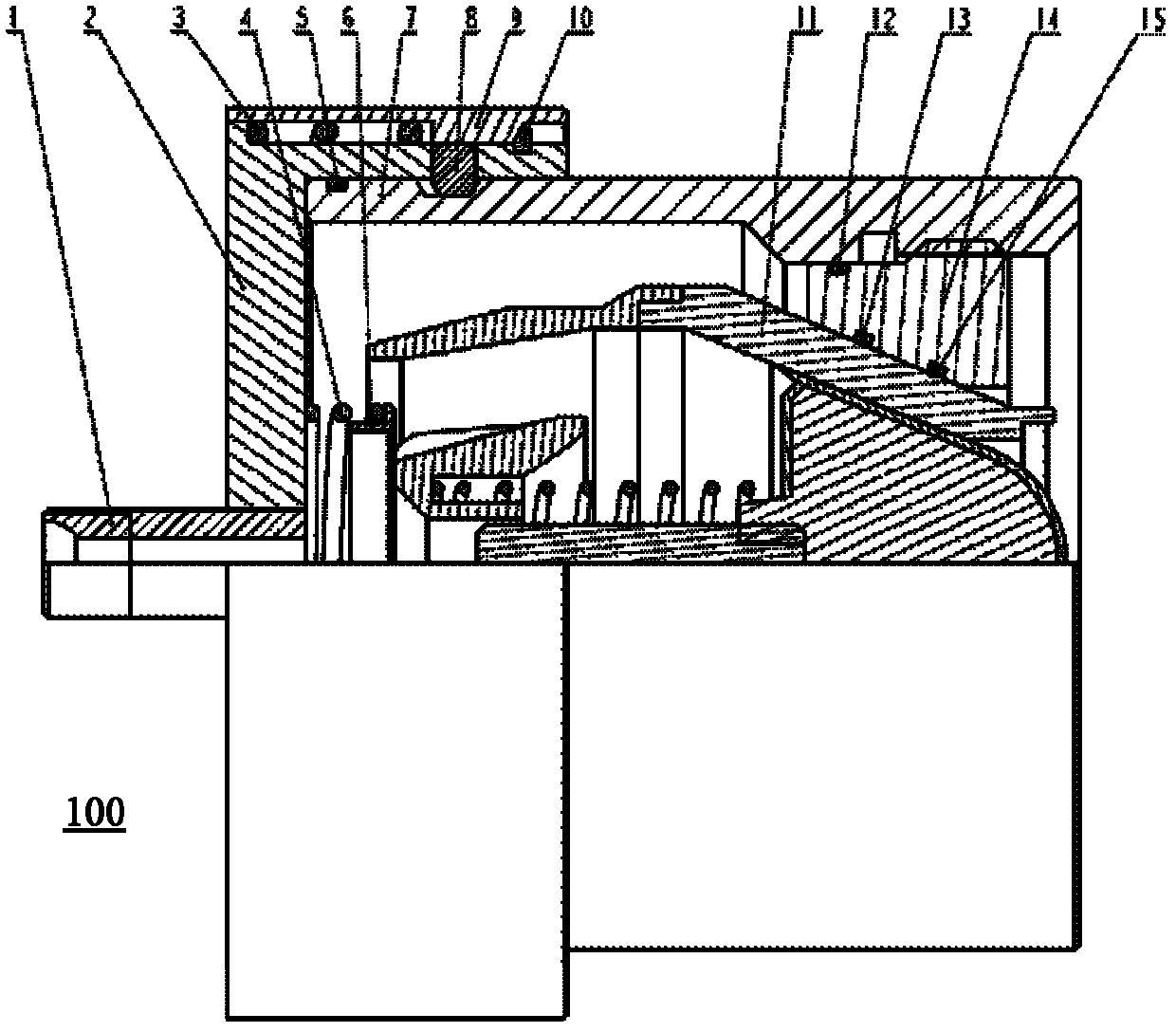

[0025] figure 1 Shown is a one-way valve pressure-bearing detection device 100 according to the present invention, which is used to detect the pressure-bearing capacity of the one-way valve 11 . The one-way valve 11 can especially be a one-way valve used for cement-type floating shoes. However, it can be understood that the pressure detection device of the present invention is also applicable to any type of one-way valve.

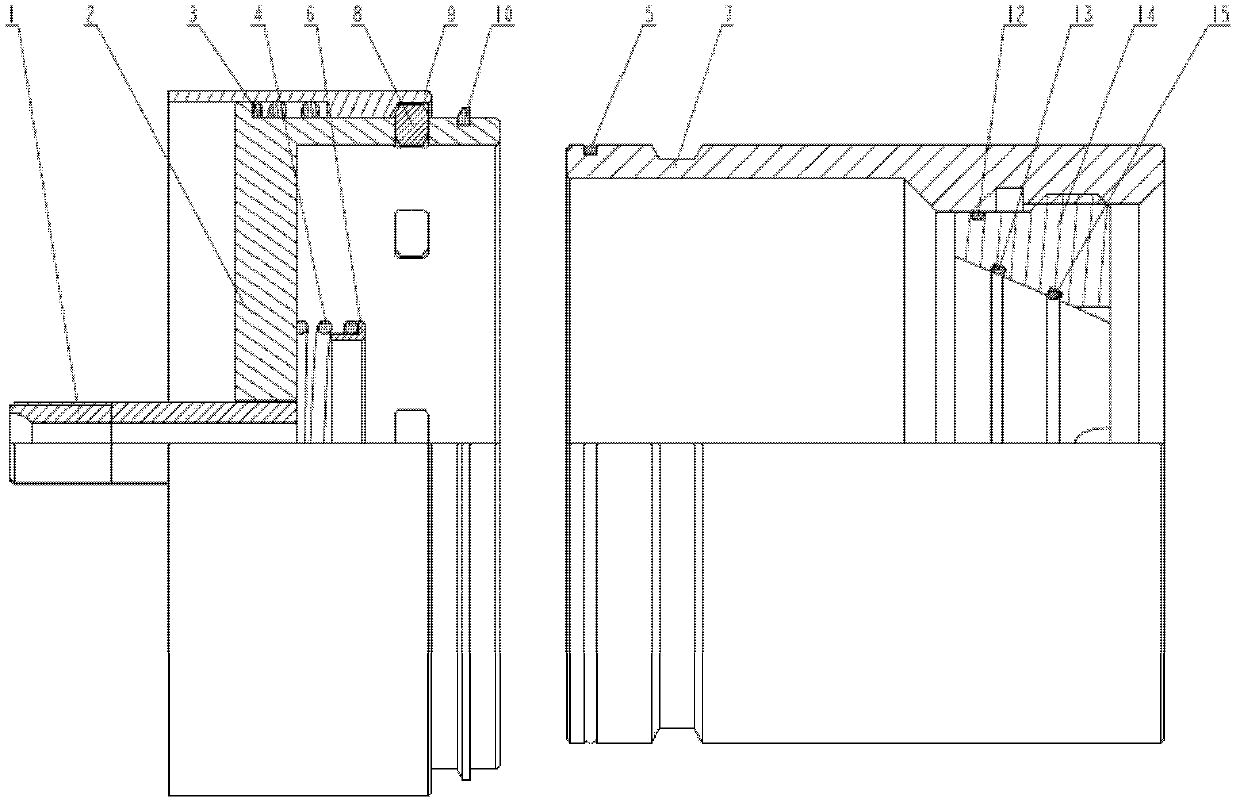

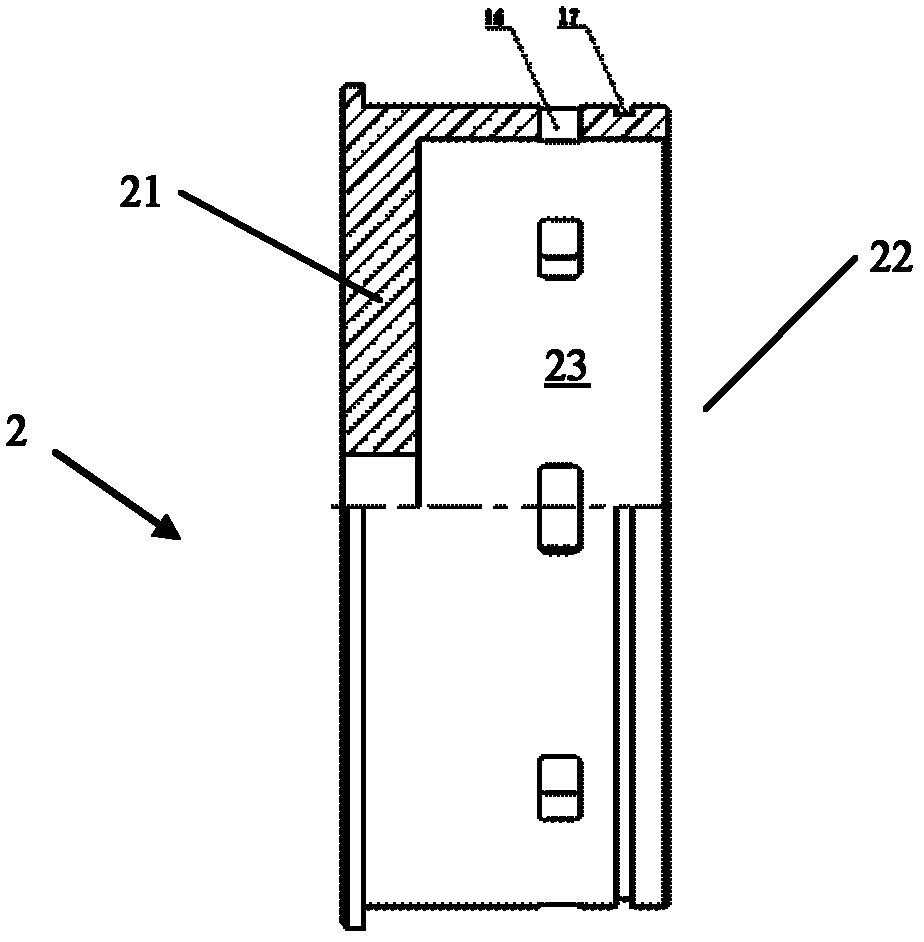

[0026] Such as figure 1 and 2 As shown, the one-way valve pressure detection device 100 includes a sealing head 2, which is substantially cylindrical, including a closed end 21, an open end 22 and a side wall formed between these two ends. Such as image 3 As shown, an internal cavity 23 is defined within the closure head 2 .

[0027] The one-way valve pressure detection device 100 also includes a body 7 that can be installed in the inner cavity 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com