Fission neutron converter

A fission neutron converter technology, which is applied in the field of reactor fuel assembly positioning grid out-of-reactor test devices, can solve the problems of large size of neutron converter fuel elements, which is not conducive to improving power density, etc., to achieve increased power, The effect of increasing the neutron fluence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

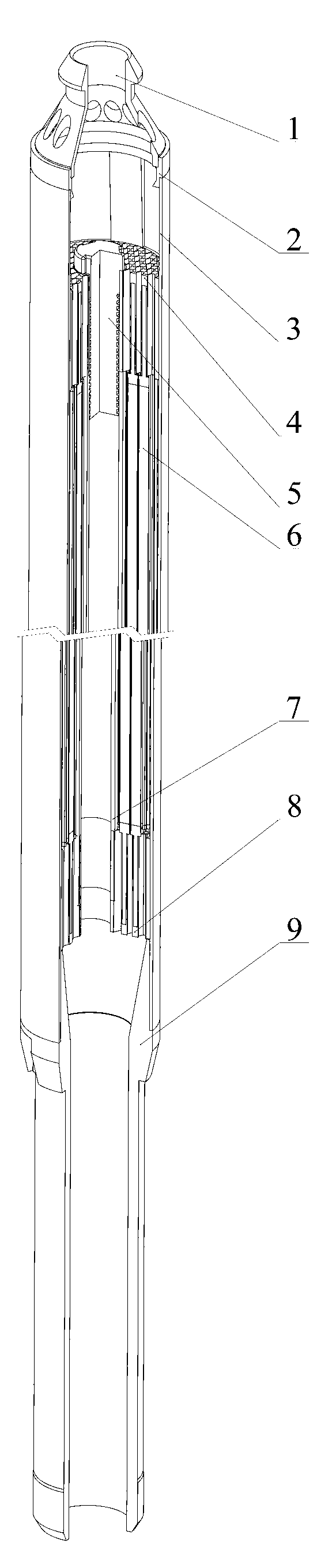

[0024] Such as figure 1 As shown, the fission neutron converter of the present invention includes an inner casing 7 and an outer casing 3 coaxially fitted with the inner casing 7, and two ends between the inner casing 7 and the outer casing 3 are respectively installed with The upper grid plate 4 and the lower grid plate 8, the upper grid plate 4 and the lower grid plate 8 are exactly the same in structure size, and the upper grid plate 4 and the lower grid plate 8 are provided with 64 fuel rod installation counterbores, The holes are arranged in a triangular lattice and connected by ribs. The number and arrangement of the counterbore holes are calculated based on the mutual coupling calculation of reactor physics and thermal engineering, and the mechanical structure is continuously optimized. The ribs form a rhombic cooling water flow channel. 64 cross-shaped fuel rods 6 are inserted between the upper grid plate 4 and the lower grid plate 8, and a throttle plug 5 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com