Wire branch connector

A technology of connectors and branches, applied in the direction of multi-conductor connectors, conductive connections, connections, etc., can solve the problems of easy natural loosening, unsafe electricity use, burning, etc., and achieve the effect of overcoming the connection of branch wires and the safety of electricity use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

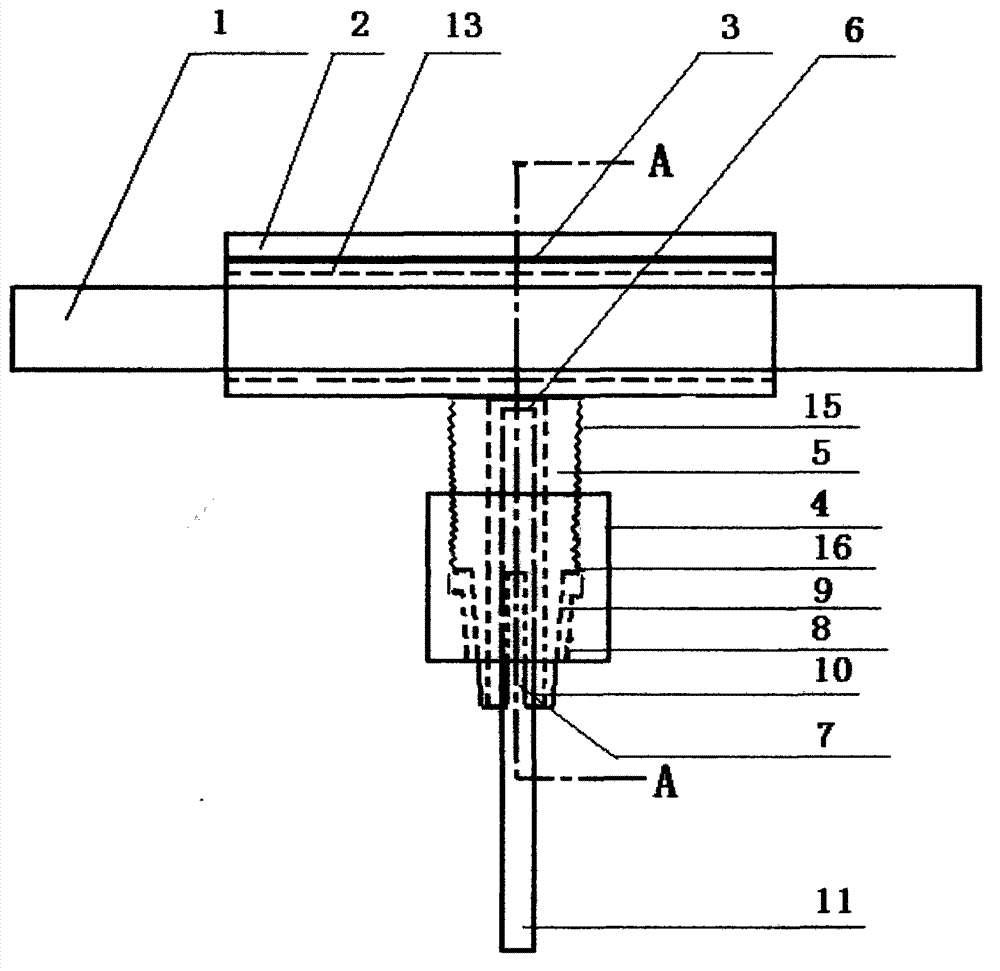

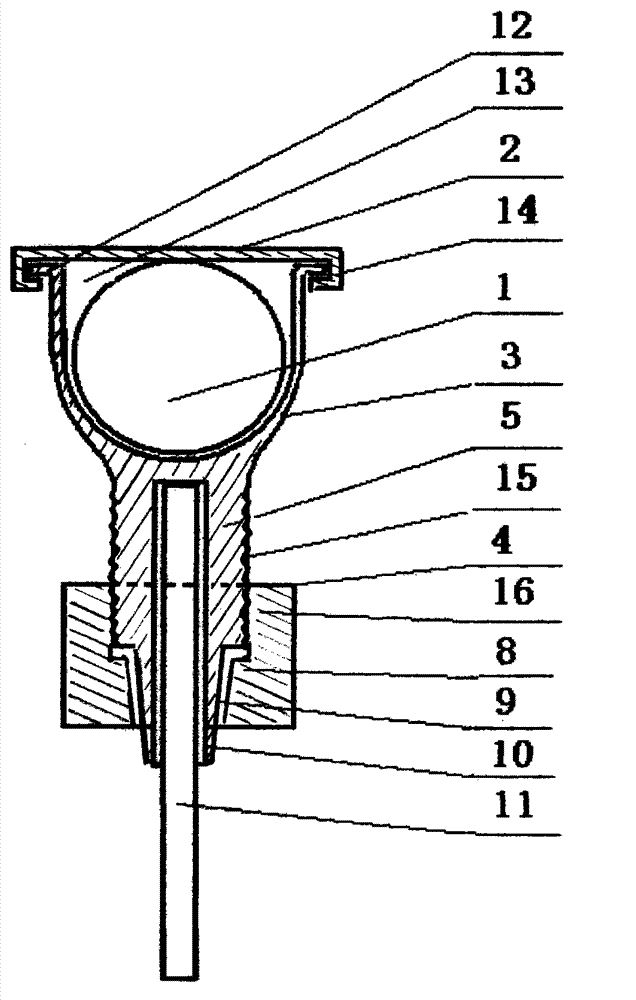

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments and its use and operation.

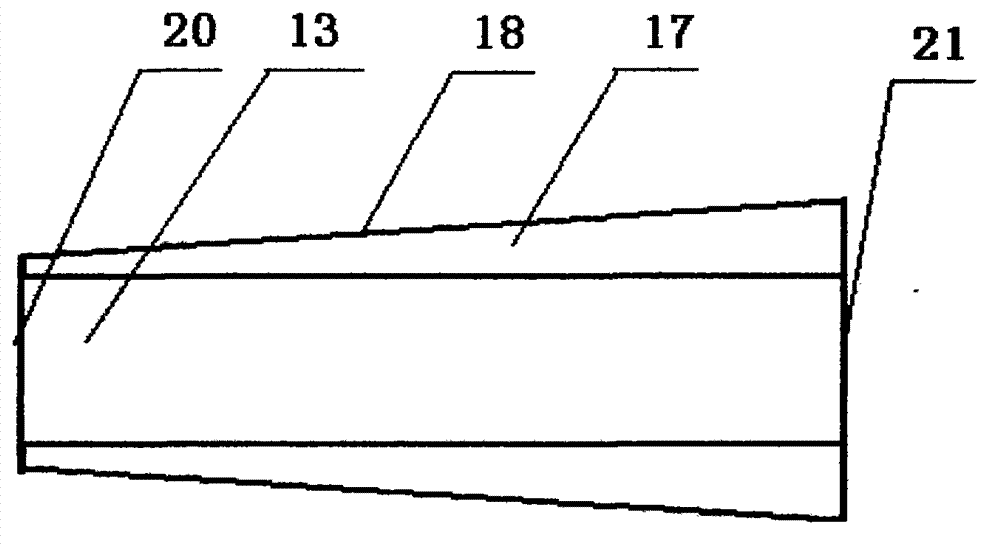

[0017] In the figure: the wire clip (3) and the branch rod (5) form a T-shaped conductive whole, the wire clip part is composed of the wire clip (3) and the wire clip cover (2), and the branch line is formed by the branch rod (5) ), a tightening nut (4); there is a U-shaped long slot (13) for embedded power supply main wire in the clip (3), and there is a symmetrical one with a large head and a small tail on both sides of the U-shaped long slot opening. 7-shaped curved plane (17); the clamp cover (2) cover surface becomes a decent shape ( Figure 4 ), the angles of its four corners are equal to the angles of the four corners of the 7-shaped curved plane (17) on both sides of the U-shaped long groove of the wire clip clip, and a hook-shaped groove (14) is respectively arranged below the two sides; the wire clip plane ( image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com