Copper plating process of flexible circuit board and copper-plating hanging basket thereof

A technology of flexible circuit boards and immersion copper, applied in printed circuit, printed circuit manufacturing, metal material coating process, etc., can solve the problems of low production efficiency of hanging baskets, reduction of wrinkle defect rate, Teflon wire wrinkle, etc., to achieve Eliminate hanging basket marks, improve manufacturing capacity, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

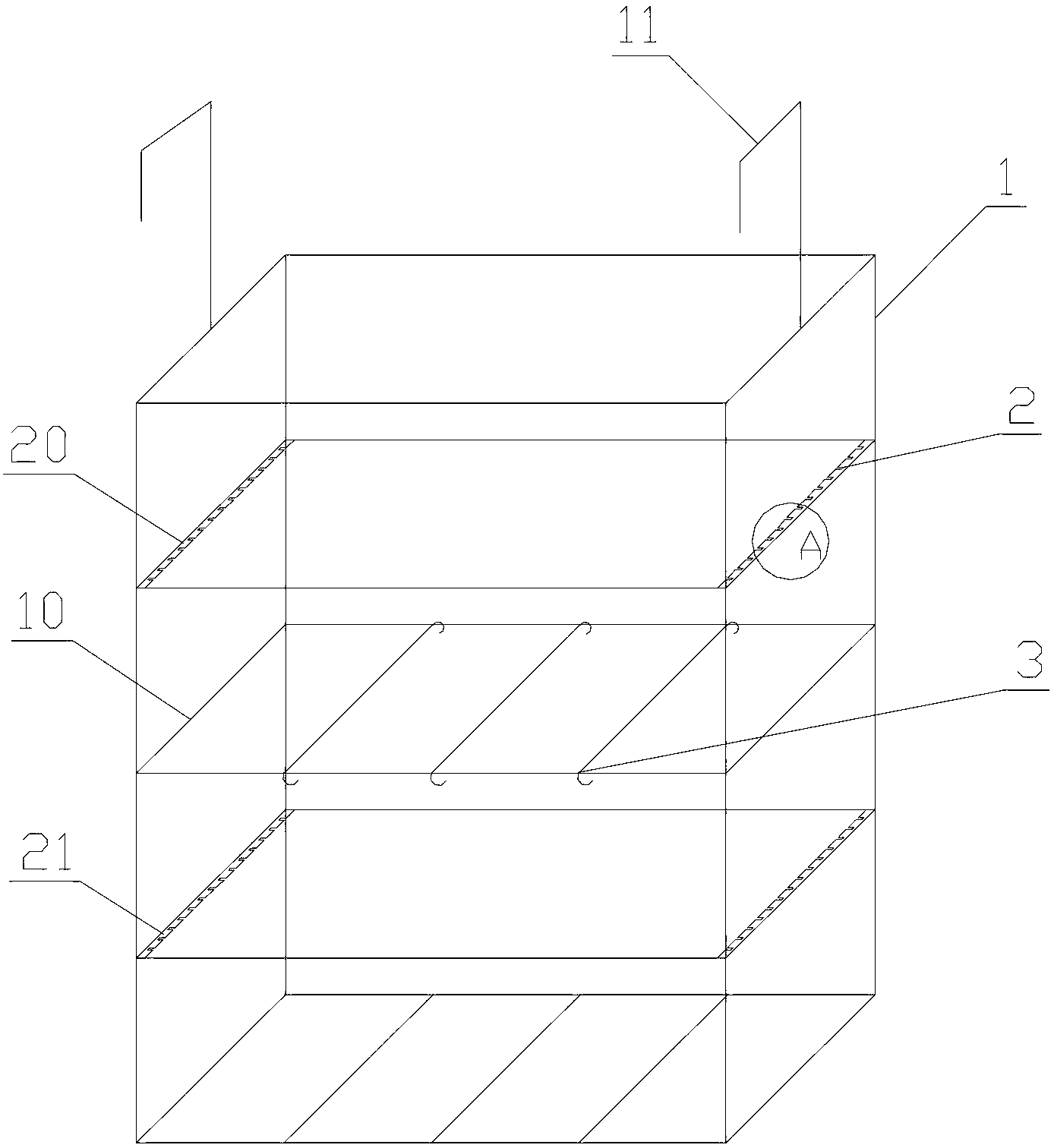

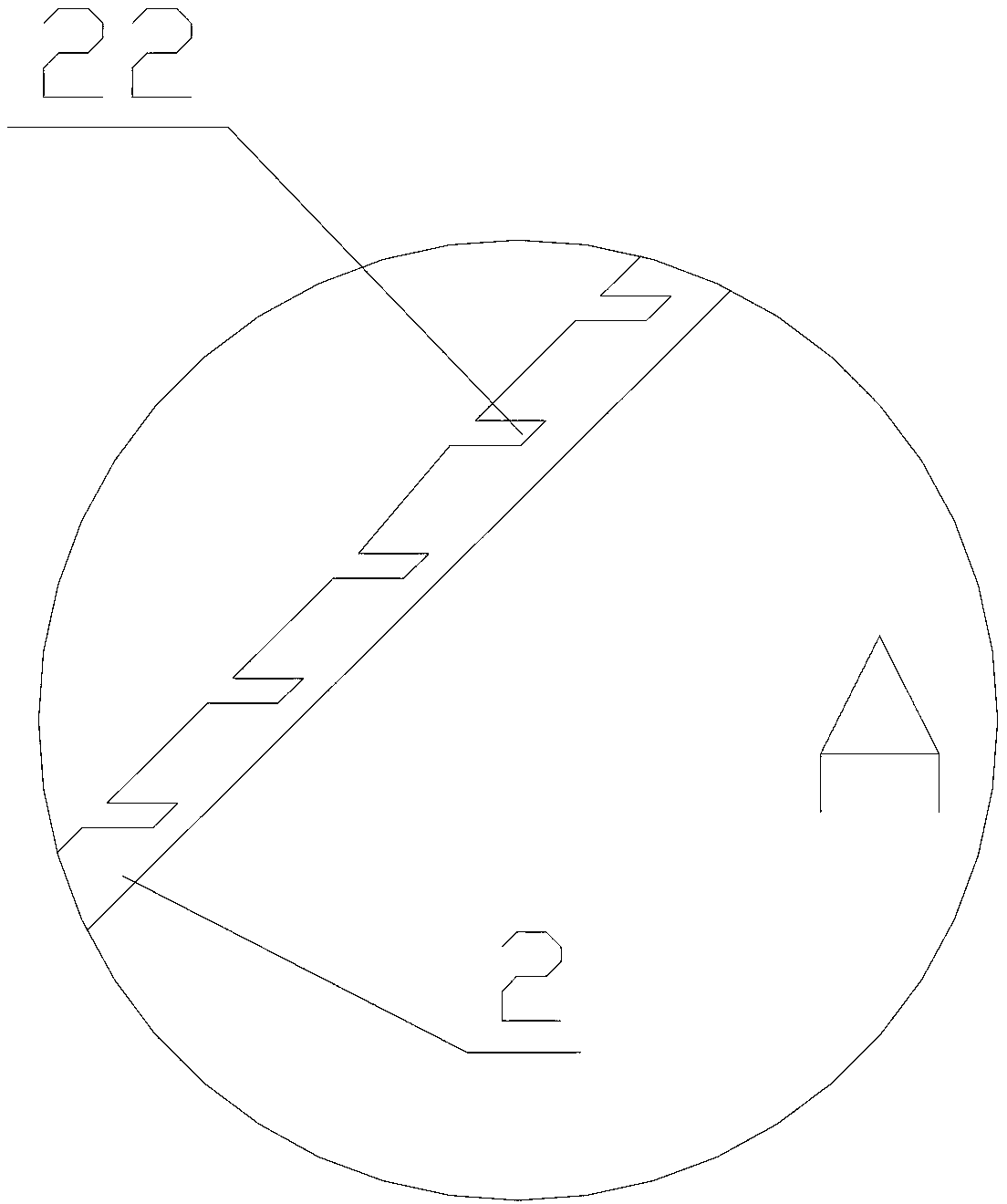

[0029] In order to solve the problems of hanging basket marks and wrinkles in the FPC production process, the present invention innovates and improves both the hanging basket and the way of loading the board. The present invention changes the traditional design idea, in order not to produce hanging basket marks, it must not touch; in order not to produce wrinkles, it must be less touched, so the product is fixed for production.

[0030] Such as Figure 1 to Figure 5 As shown, the low-wrinkle manufacturing process of flexible circuit boards without hanging baskets includes a copper sinking process, and the steps of the copper sinking process are as follows:

[0031] (1) Put the strong clamp 9 into the strong clamp pusher 8;

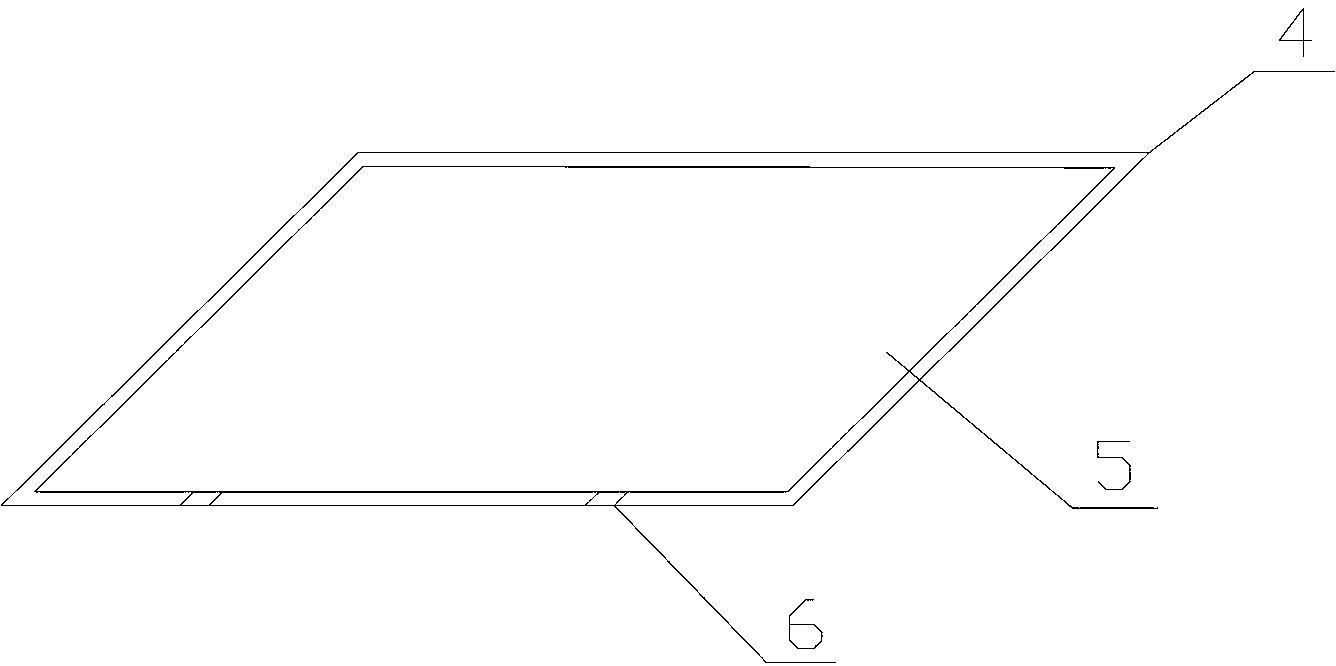

[0032] (2) Insert the sub-basket 4 with the limiting convex point facing upwards into the annular mounting surface of the upper platform 7, and then place the FPC copper-clad plate 5 flatly along the sub-basket limiting point 6, and use The clamp pusher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com