Corn threshing machine

A corn thresher, consistent technology, used in threshing equipment, hand tools, agricultural machinery and implements, etc., can solve the problems of scratching the operator, low efficiency, unsanitary, etc., to achieve easy maintenance, high hardness and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

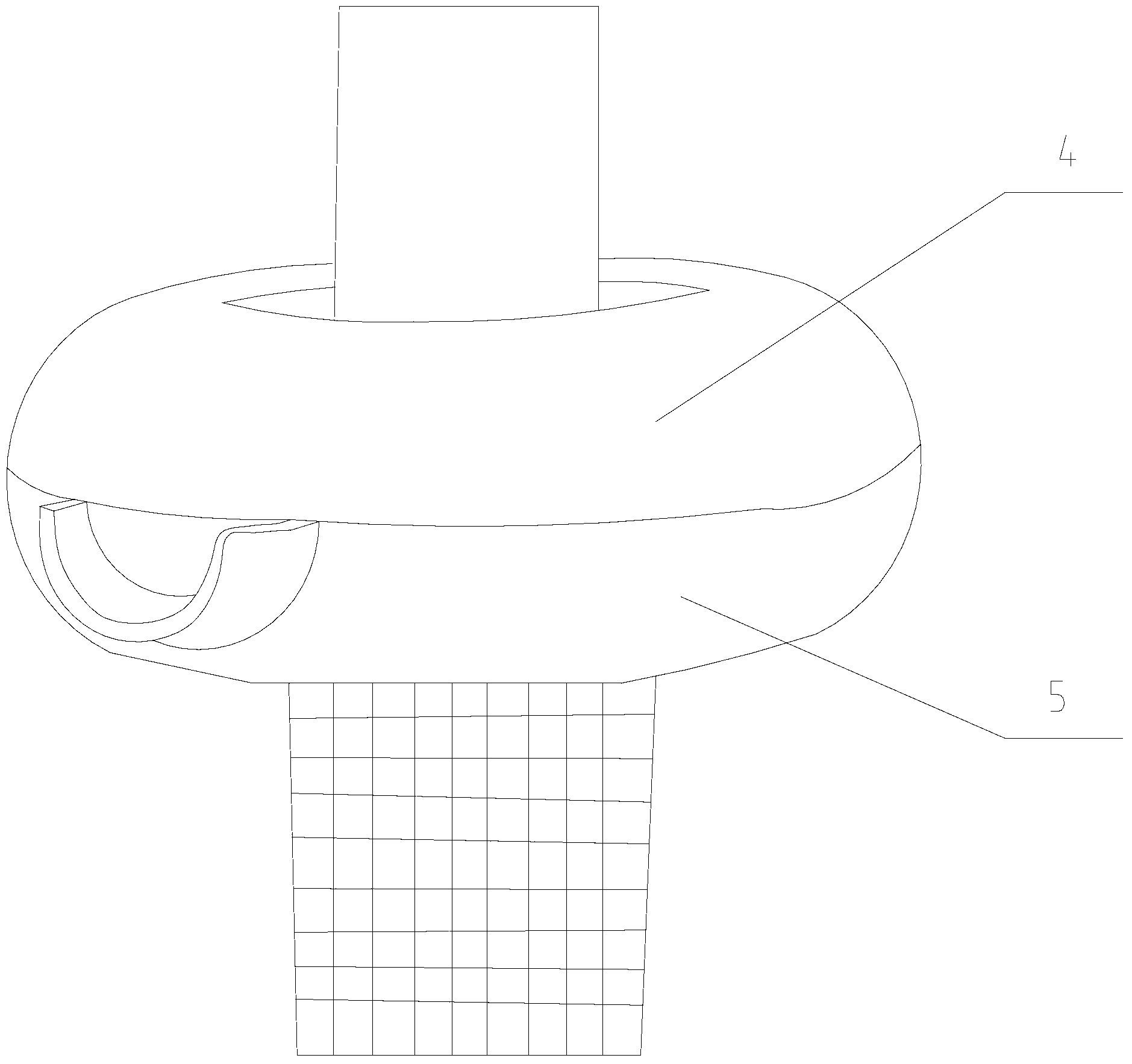

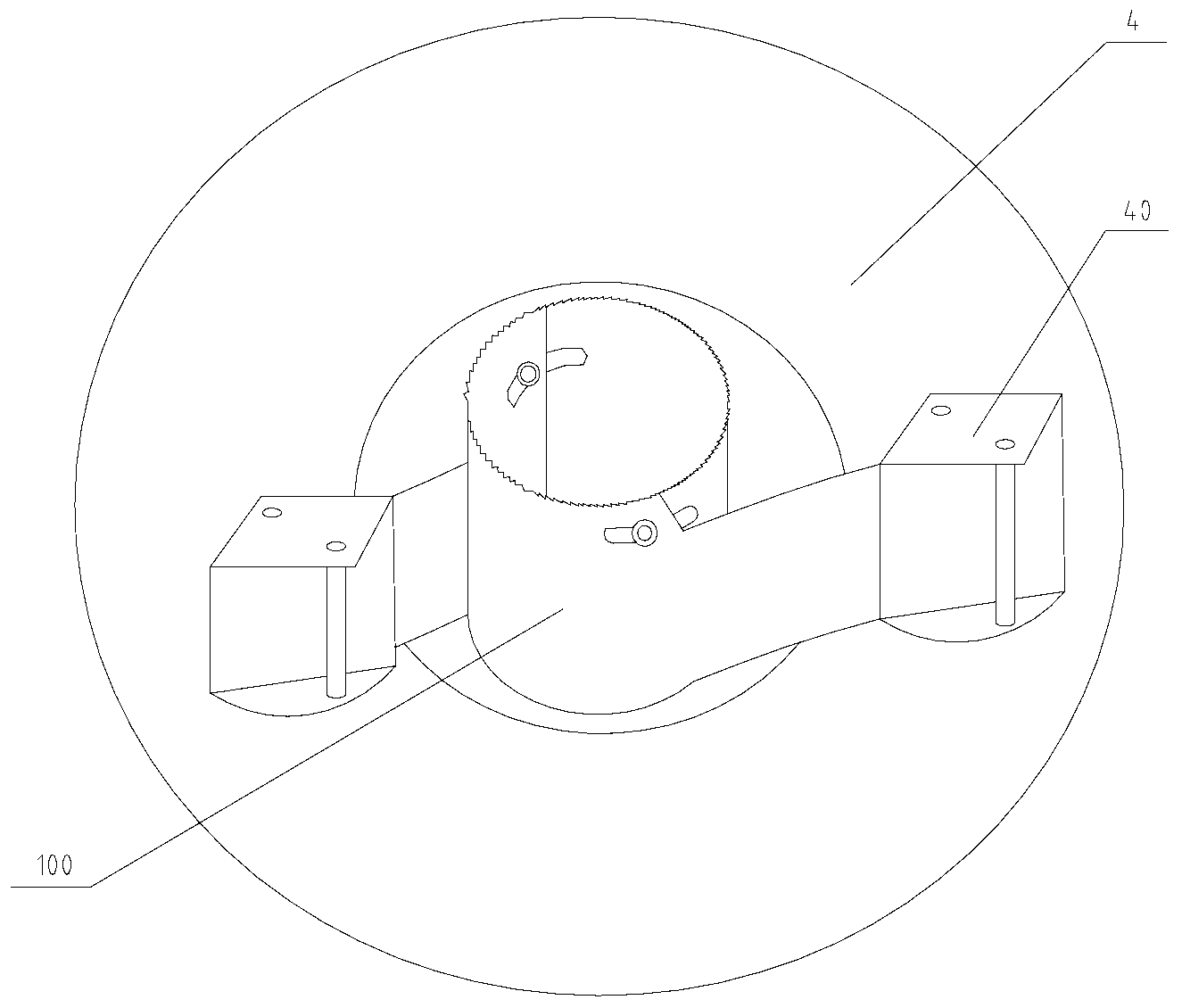

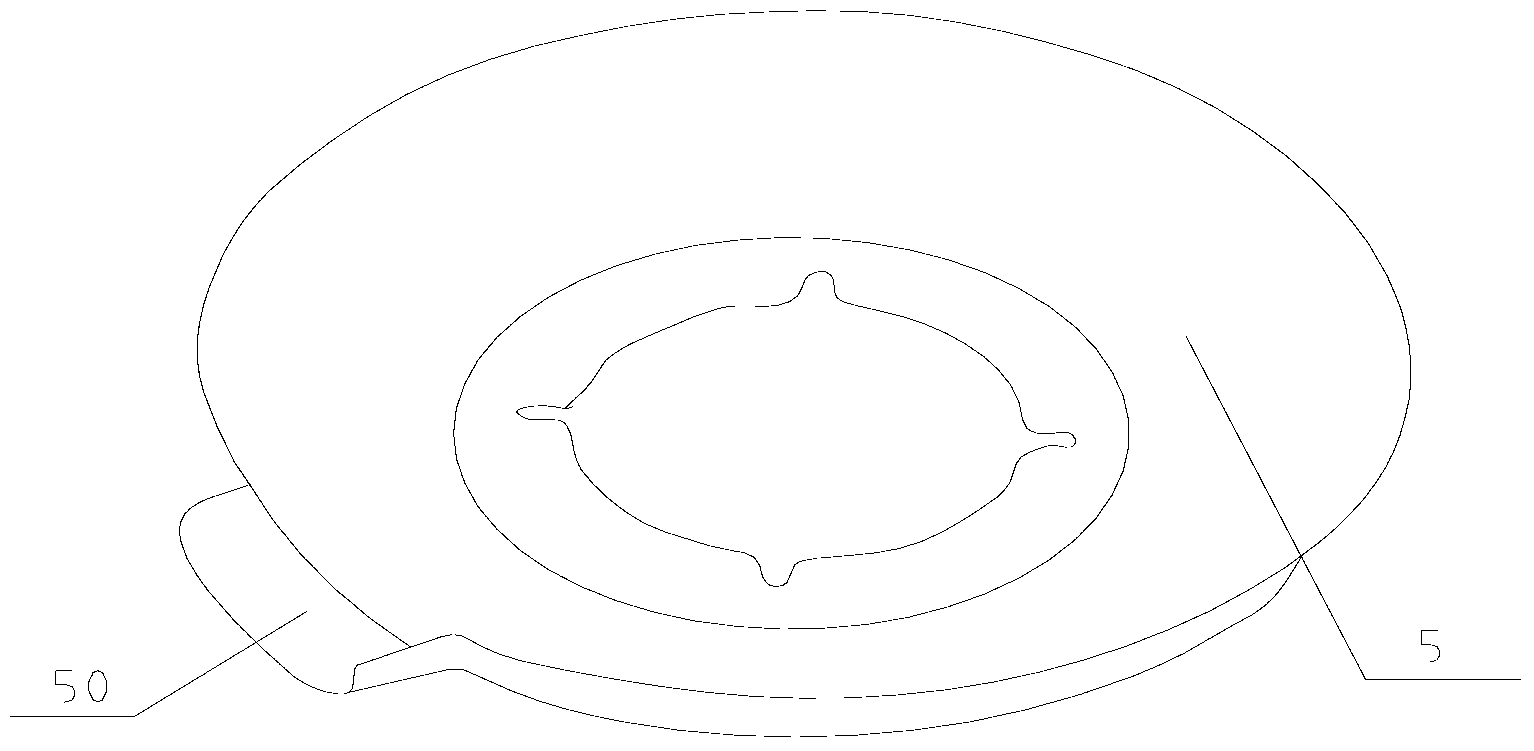

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the corn thresher of the present embodiment includes a blade loam cake 4, a collection tray 5 fastened with the blade loam cake 4, and the edge of the collection tray 5 has a discharge port 50, and the blade loam cake 4 is made of transparent plastic material. Easy to observe. The centers of the blade loam cake 4 and the collection tray 5 are provided with circular holes of the same size, and the blade loam cake 4 is provided with a cylindrical knife set 100, and the center of the cylindrical knife set 100 is aligned with the center of the circular hole of the blade loam cake. , the two ends of the cylindrical knife set 100 are fixed on the inner surface of the blade loam cake 4 by two clip frames 40, the two clip frames 40 are arranged along the center line of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com