Steel wire automatic butt welding processing machine

A technology for processing machines and steel wires, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of reducing the welding quality of steel wires, weak welding, low welding quality, etc. The effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

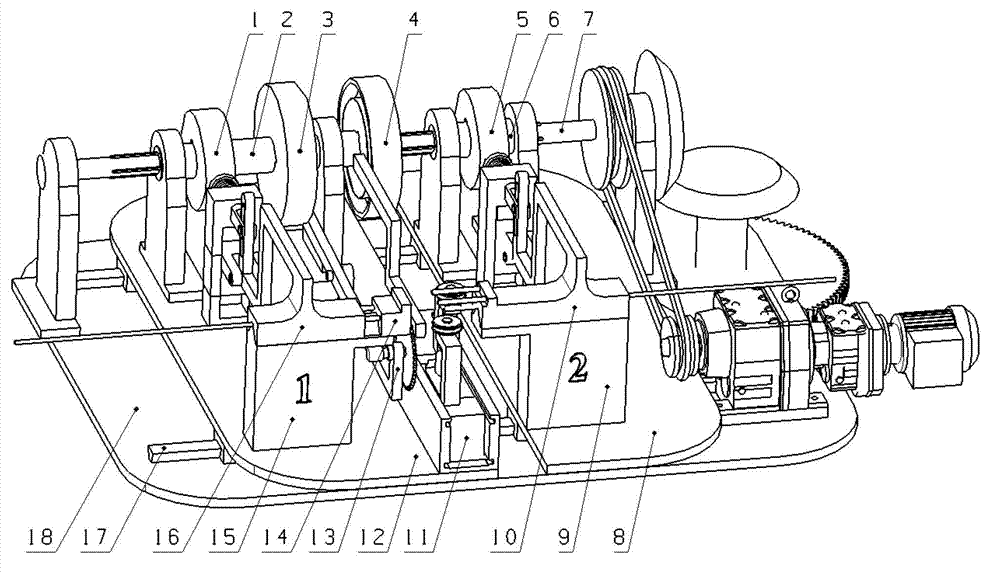

[0046] Implementation of the drive mechanism: such as figure 1 , 3 as shown,

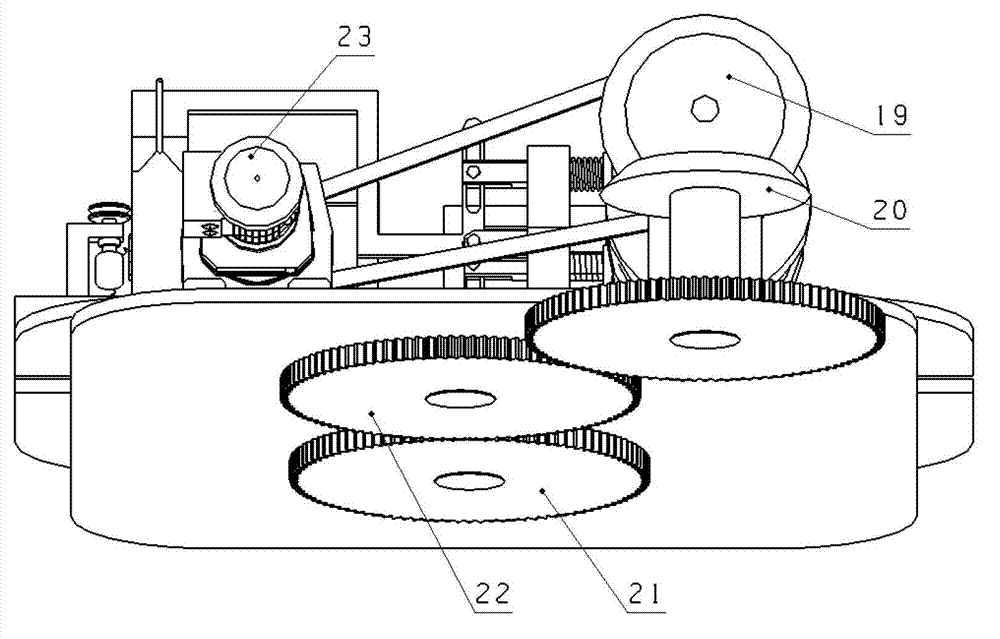

[0047] The drive shaft 7 is installed on the fixed plate 18 through the bearing seat, and the motor 23 and the drive shaft 7 are driven by a chain.

[0048] The bevel gear 19 is fixed on the drive shaft 7 and rotates with it, the bevel gear 20 is installed on the fixed plate 18, the bevel gear 20 meshes with the bevel gear 19; the gear 21 meshes with the gear 22, and the gear 22 passes through the gear fixed with the bevel gear 20 Engaged and rotated with the bevel gear 20, the gear 21 and the gear 22 respectively drive the translation plates 12 and 8 of the welding machine to slide along the guide rail 17.

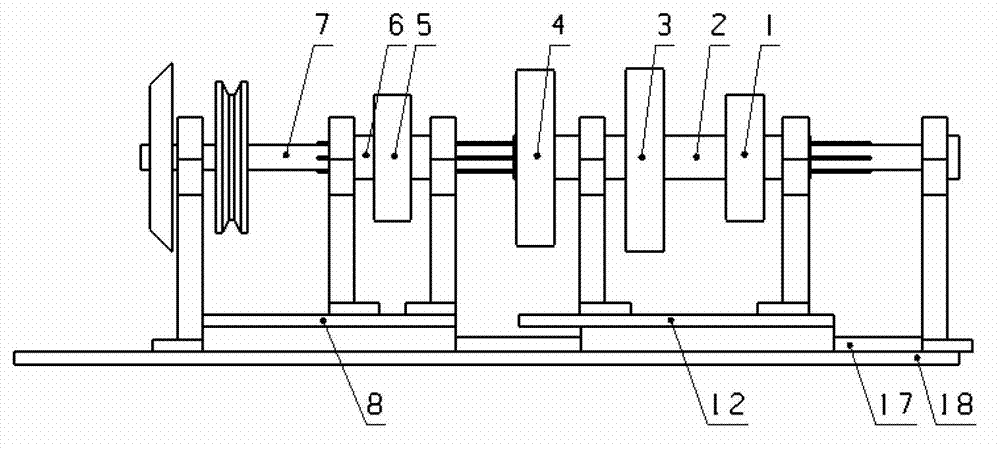

[0049] The implementation of the grabbing mechanism: such as figure 1 , 4 as shown,

[0050] The wire grabbing cams 1 and 5 are respectively fixed on the sliding bushings 2 and 6 by key connection, the sliding bushings 2 and 6 are set on the drive shaft 7 by spline connection, and the brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com