Cooperative target capture locking device

A locking device and cooperation target technology, applied in the field of robots, can solve the problems of large impact force, poor capture reliability, small capture tolerance, etc., and achieve the effect of small impact force, reasonable design, and reduced collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

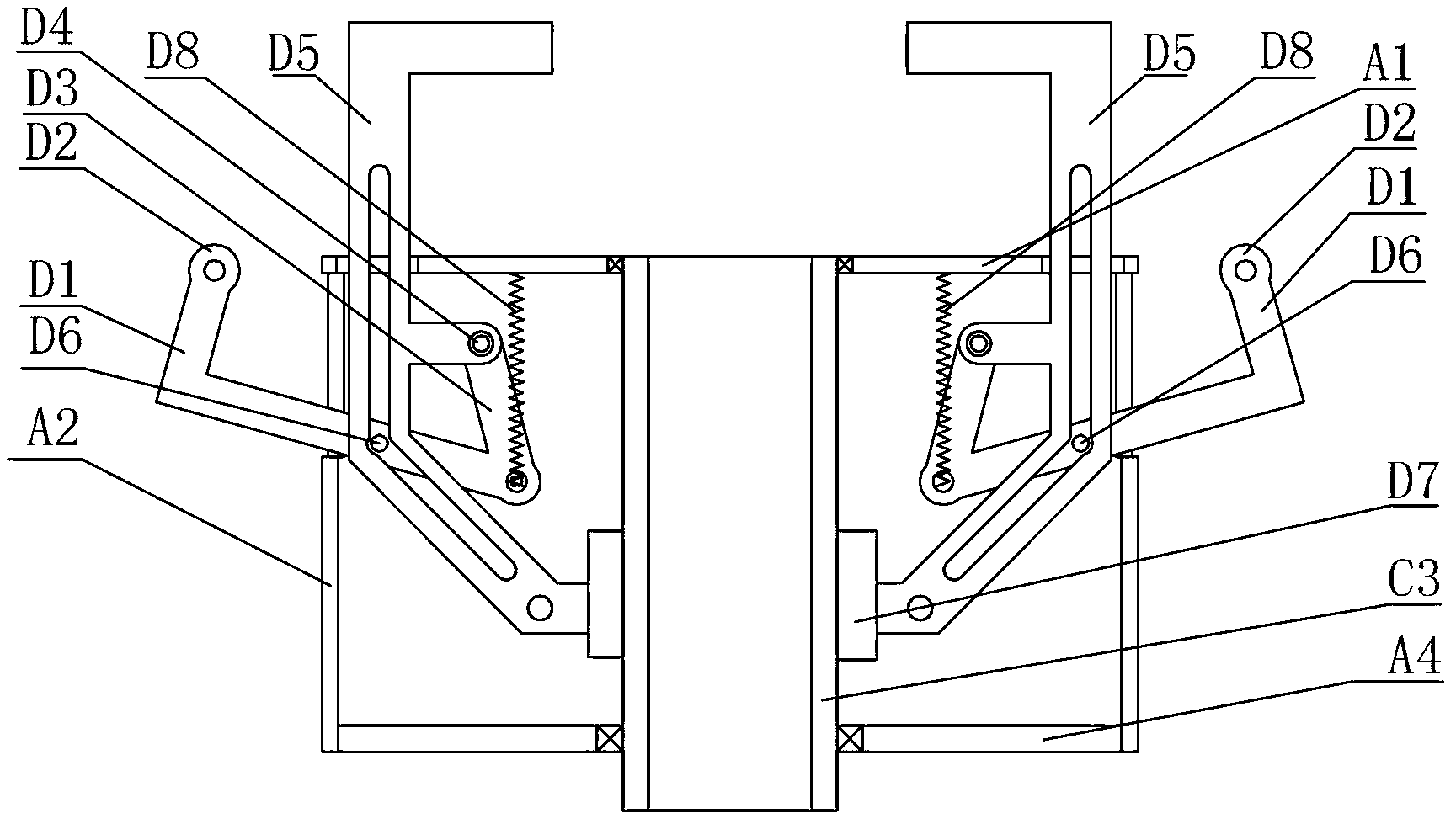

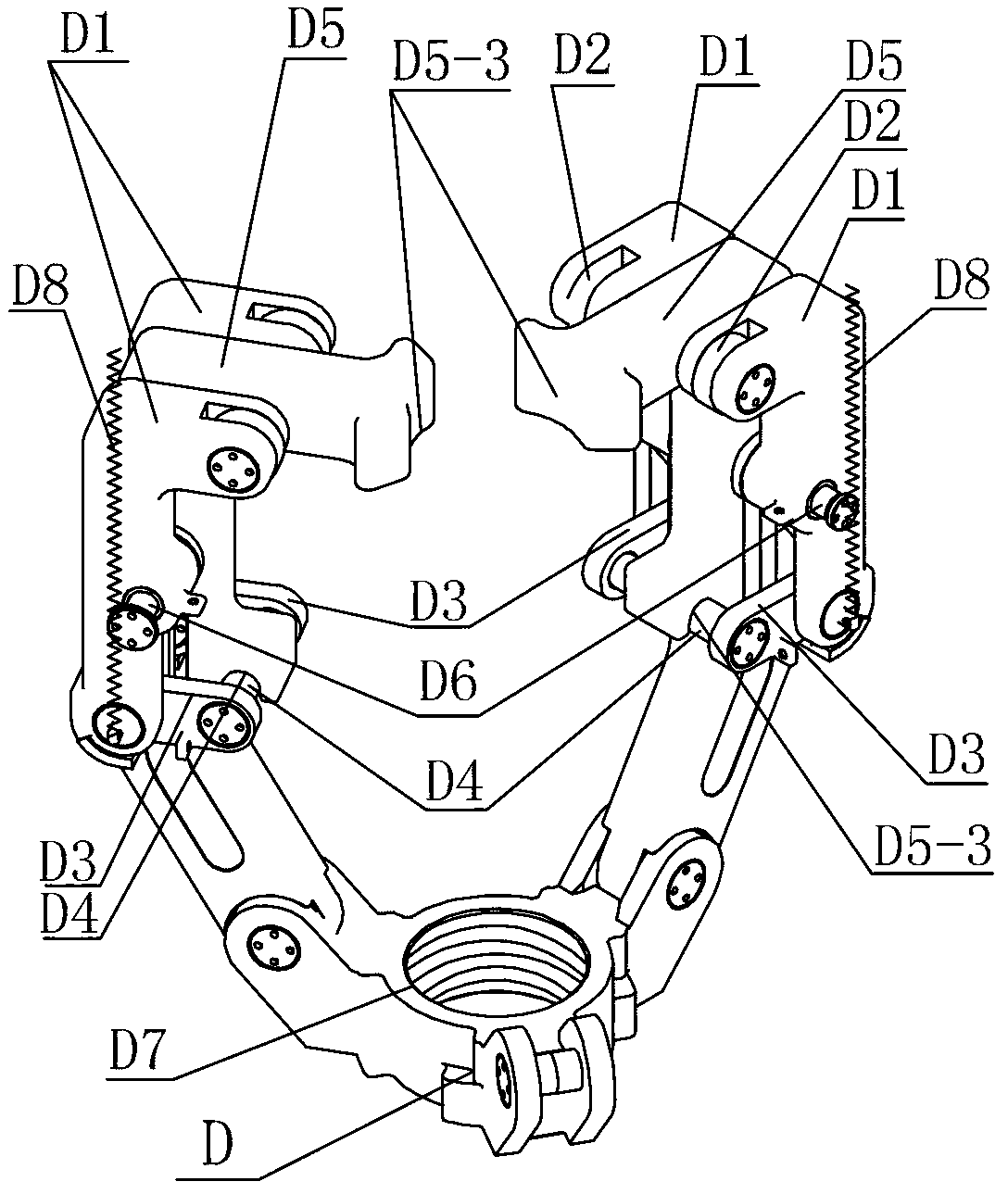

[0007] Specific implementation mode one: combine Figure 1-Figure 3 To illustrate this embodiment, a cooperation target capturing and locking device of this embodiment includes a cover plate A1, a supporting shell A2, a bottom plate A4, a lead screw C3, a disc D7 and three sets of capturing and locking fingers;

[0008] The supporting shell A2 is a cylindrical shell, the cover plate A1 is connected to the upper end of the supporting shell A2, the bottom plate A4 is installed on the lower end of the supporting shell A2, the lead screw C3 is arranged along the axis of the supporting shell A2, and the lead screw C3 The upper end of the screw is connected to the cover plate A1 in rotation, and the lower end of the lead screw C3 is connected to the bottom plate A4 in rotation. Each group of capturing and locking fingers includes a capturing claw D5, a linkage shaft D4, a guide column D6, two locking claws D1, and two locking claws. Wheel D2, two connecting rods D3 and two springs D...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 The present embodiment will be described, and the screw C3 described in the present embodiment is a ball screw. With such settings, the performance is reliable and stable. Others are the same as in the first embodiment.

specific Embodiment approach 3

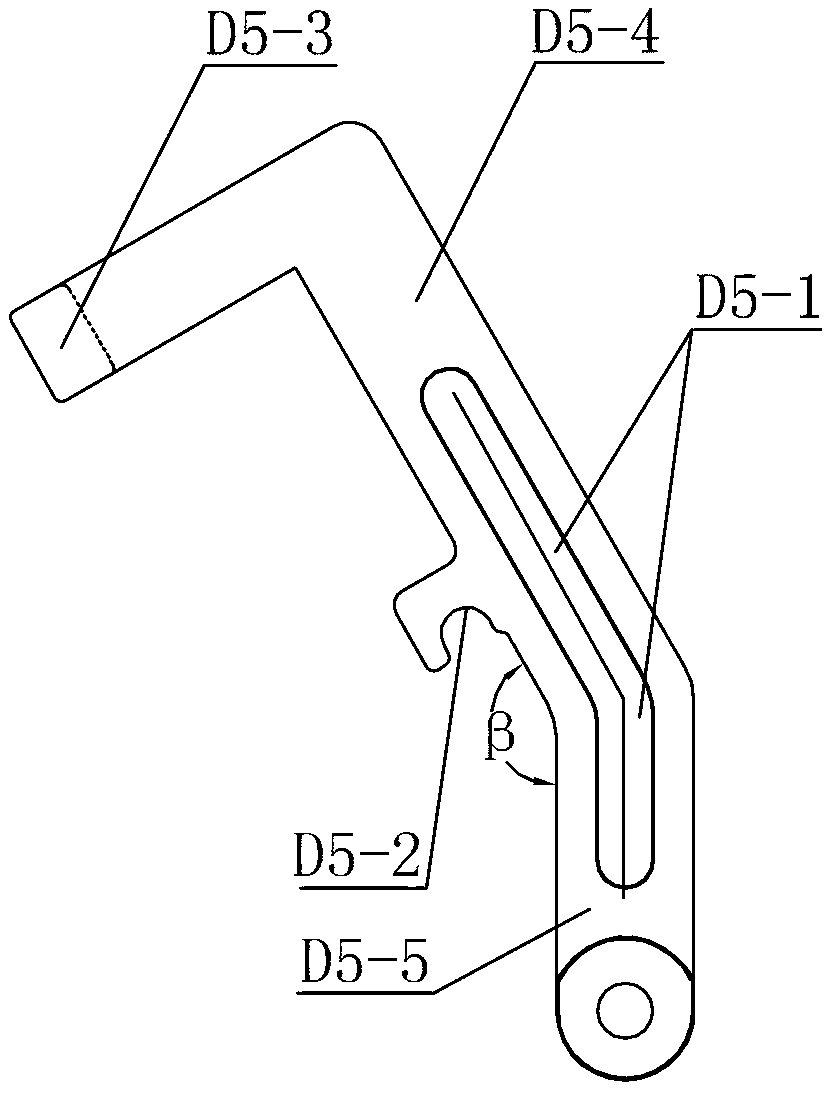

[0010] Specific implementation mode three: combination figure 2 and image 3 To describe this embodiment, the guide hole D5-1 in this embodiment is arched. With such arrangement, the catch claw and the locking claw can be well opened and closed, and the pre-tightening and locking are well realized. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com