Welding equipment for electronic tag cigarette packing box

A technology of welding equipment and electronic tags, which is applied in the field of welding equipment, can solve problems such as low welding efficiency, inability to mass produce, and low tensile strength, and achieve the effects of convenient operation, simple structure, and guaranteed tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

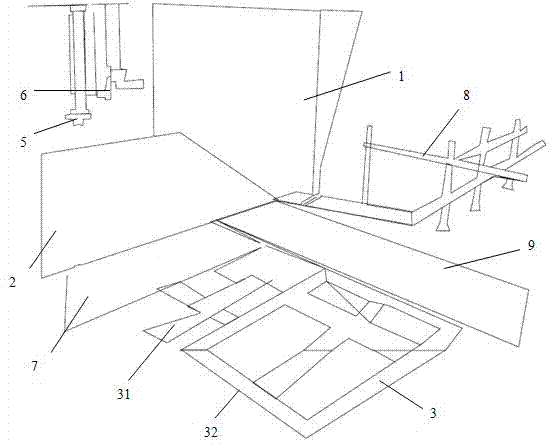

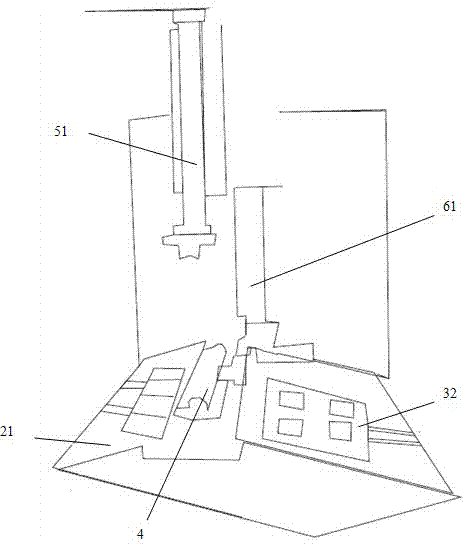

[0016] The following describes the present invention in detail with reference to the accompanying drawings:

[0017] Such as figure 1 As shown, the welding equipment used in the electronic label cigarette packaging box of the present invention includes an equipment box body 1. On the equipment box body 1 is provided a guide mold 2, two entanglers 3, an upper mold 4, a lower mold 5, and light and heat The welding head 6, the feeding positioning device 7 and the feeding trough 8, wherein the embracer 3 includes a transmission part 31 and an embrace plate 32. One end of the embrace plate 32 is connected to the output end of the transmission part 31, and the other end of the embrace plate 32 is at The transmission part 31 can be encapsulated on the two entanglement surfaces 21 of the guide mold 2. The guide mold 2 is parallelogram with one vertex upward, and the lower mold 4 is set at the top corner of the parallelogram. The upper mold 5 is located at the upper end of the lower mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com