A type of buffer support for diesel engine of armored vehicle

A type of diesel engine technology, applied in vehicle components, power units, transportation and packaging, etc., can solve the problems of poor reliability of the bearing, easy to be crushed, poor shock absorption effect, etc., to increase the buffer function and suppress resonance Peak, the effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

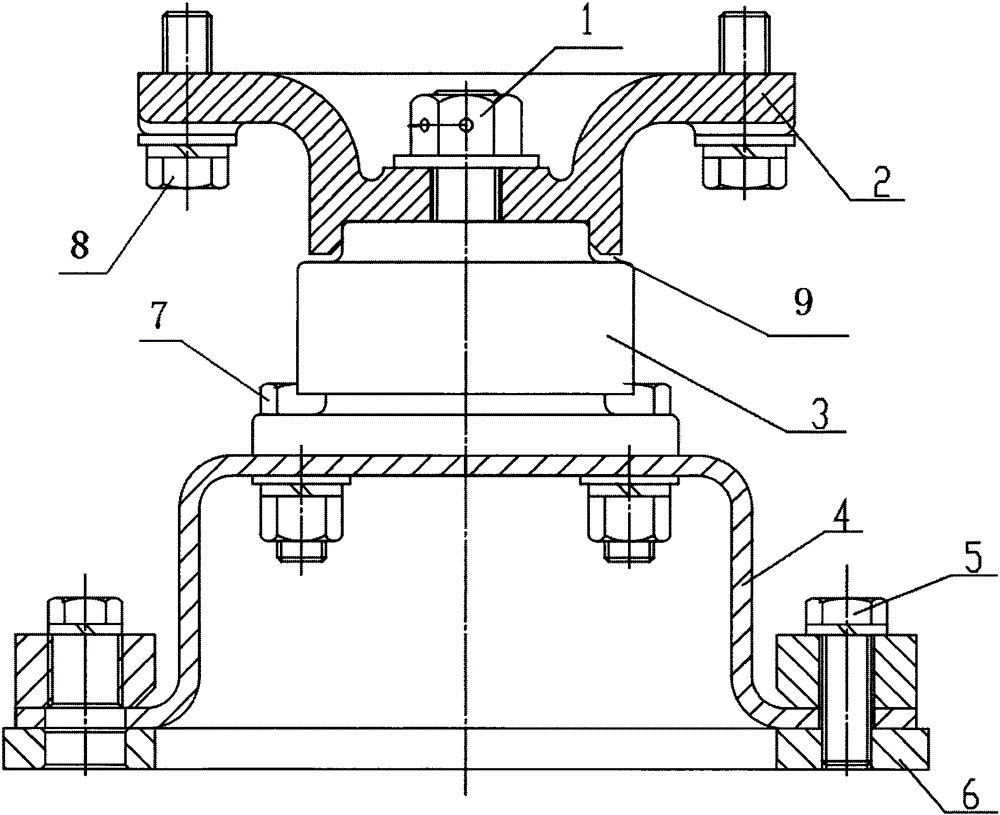

[0010] A type-shaped buffer support for an armored vehicle diesel engine, including a main shock absorber 3 and a bottom plate 6; and an upper type-shaped bracket 2, a lower type-shaped bracket 4, a nut 1, a lower connecting bolt 5, and an upper connecting bolt 7 and fixing bolts 8; the main shock absorber 3 is fixedly connected with the upper several-shaped support 2 through the nut 1; the main shock absorber 3 is fixedly connected with the lower several-shaped support 4 through the upper connecting bolt 7; the upper several-shaped support 2 is The fixing bolt 8 is connected with the diesel engine; the lower bracket 4 is fixedly connected with the bottom plate 6 through the lower connecting bolt 5 .

[0011] After the diesel engine is installed in the power cabin, when the diesel engine is faced with a large vibration, in addition to the main shock absorber, the upper and lower brackets can be deformed to absorb vibration energy, reduce vibration impact, and enhance the shock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com