Novel filling type packaging machine

A filling and packaging machine technology, applied in the field of packaging, can solve the problems of low working efficiency of the filling packaging machine, slow packaging speed, and easy shaking of the tank, so as to achieve excellent shock absorption performance, improve packaging efficiency, and protect the tank. body effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

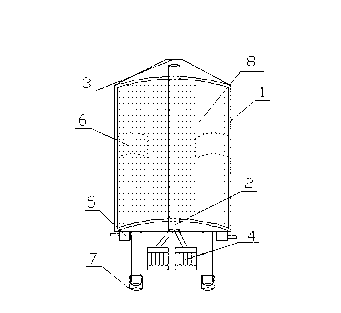

[0012] like figure 1 As shown, a new type of filling packaging machine includes a tank body 1 and a rotating shaft 2, the top of the tank body 1 is provided with a feeding port 3, the rotating shaft 2 is installed inside the tank body, and the rotating shaft 2 and At least two motors 4 are connected, the bottom of the tank body 1 is provided with at least two discharge ports 5, and the outer wall of the tank body 1 is also provided with a lead block 6, which improves the packaging efficiency. 2 discharge ports, so that the packaging work can be carried out quickly, and the lead block setting makes the can body fall more stably.

[0013] It is worth noting that the shock-absorbing pad 7 is provided at the contact part of the tank body 1 with the ground. The setting of the shock-absorbing pad makes the tank body less likely to vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com