Metering bottle cap used for powder products

A powder and bottle cap technology, applied in the directions of bottle/container cap, tightly closing the container with the cap, application, etc., can solve the problems of cumbersome access, waste, and difficult to control the amount of each time, achieve a wide range of use, avoid two The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

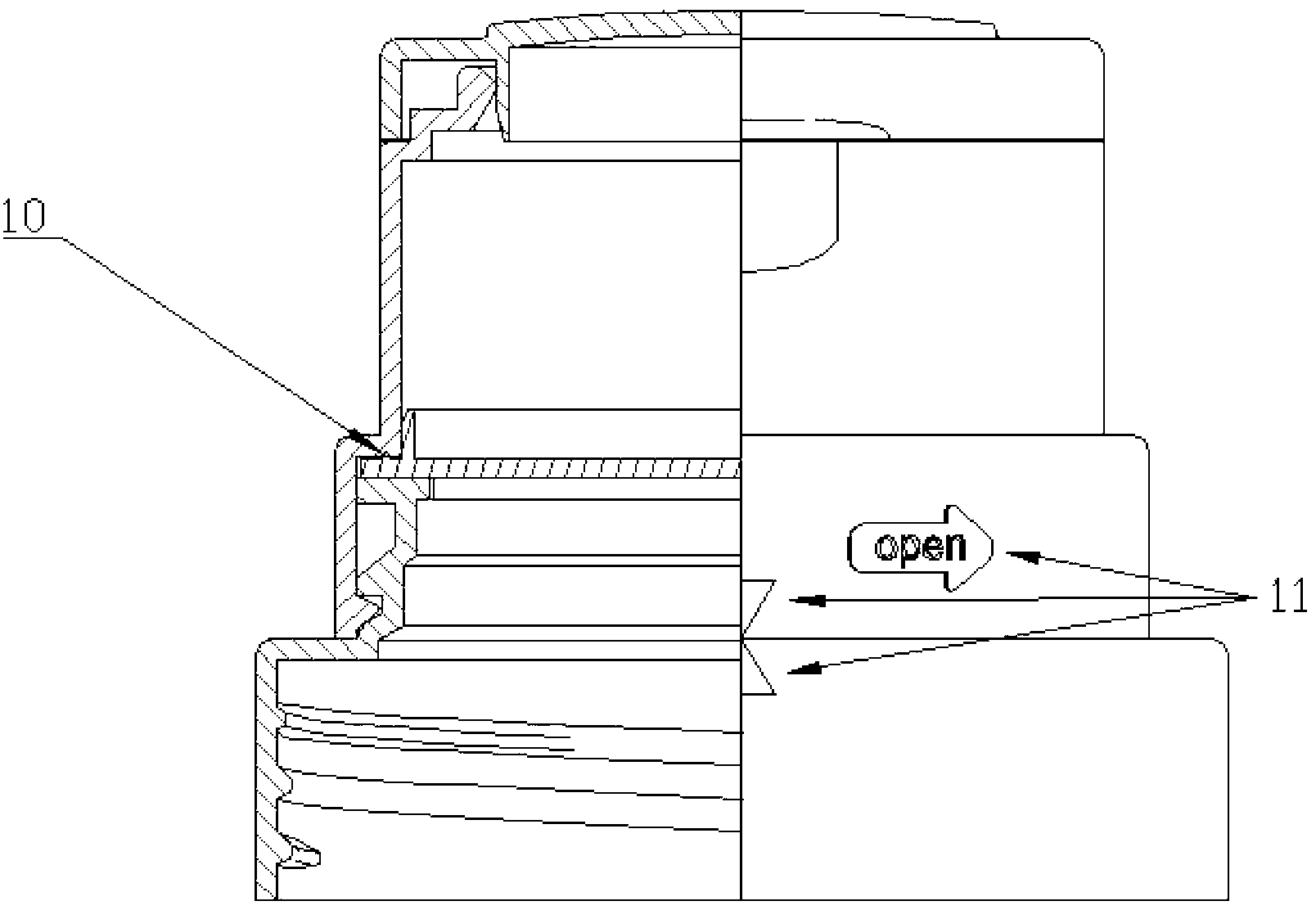

[0030] Such as Figure 1-5 As shown, a metering bottle cap for powder products, the bottle cap is installed on the powder product container, the metering bottle cap includes a flip cover, an opening and closing plate and a fixed base;

[0031] The flip cover is provided with a cover plate, a pouring hole 1, a metering chamber 2 and a bottom fixing assembly, the cover plate is connected to the upper end of the metering chamber 2 through the pouring hole 1, and the lower end of the metering chamber 2 is connected to the bottom fixing assembly;

[0032] The opening and closing disc is fixedly connected with the lower end of the metering chamber 2 in the flip cover, and is provided with a first through hole 5;

[0033] The fixed base is provided with a sliding positioning part that cooperates with the bottom fixing assembly, a second through hole 6 corresponding to the first through hole 5 of the opening and closing disc, and a threaded part 9 that is cooperatively connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com