Novel barrel yarn tension control device for dyeing

A new type of tension control technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of unfavorable dye liquor flow, large amount of bobbin yarn, large bobbin thickness, etc. Knot and waste, good quality, effect of improving tension distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

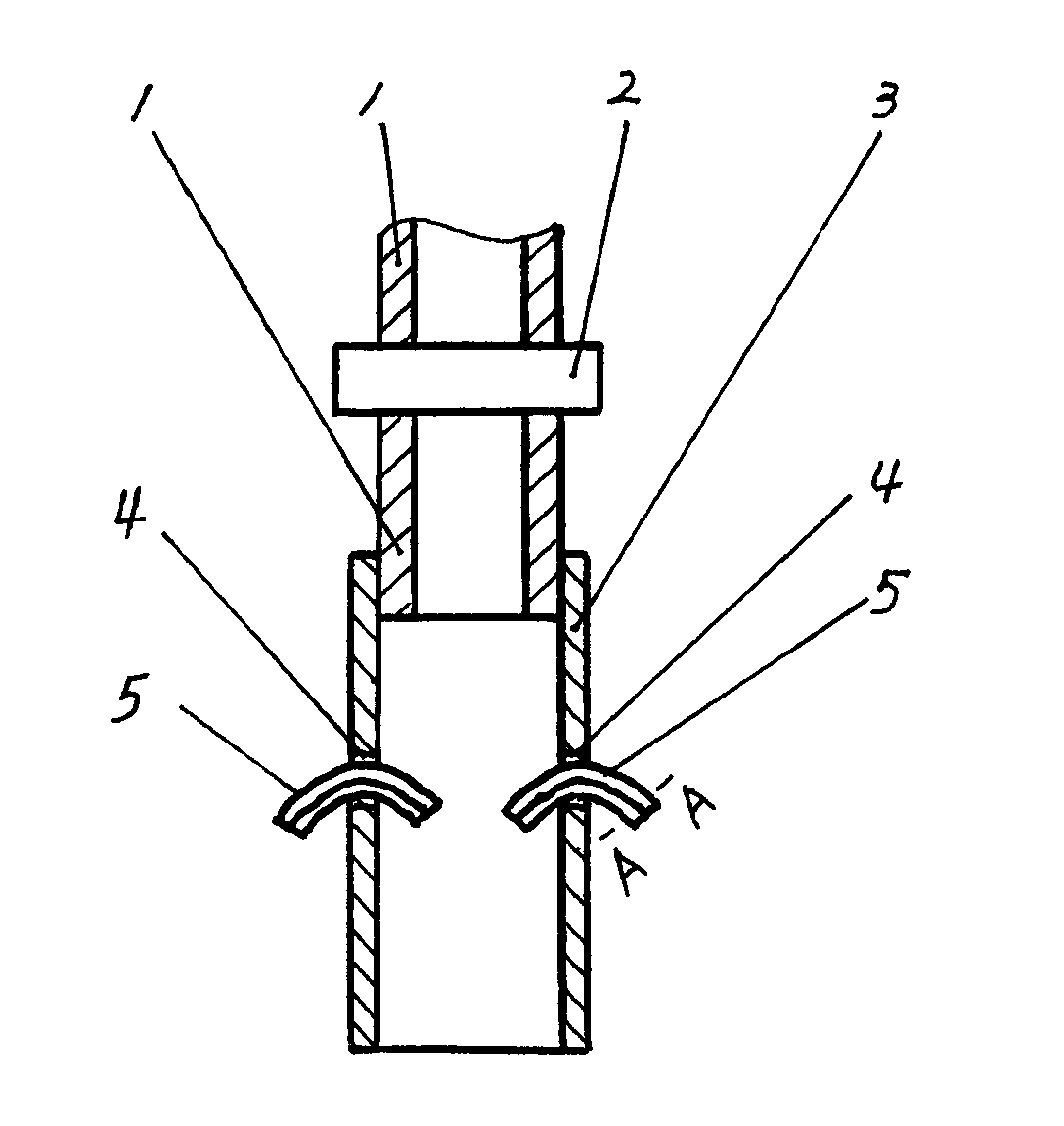

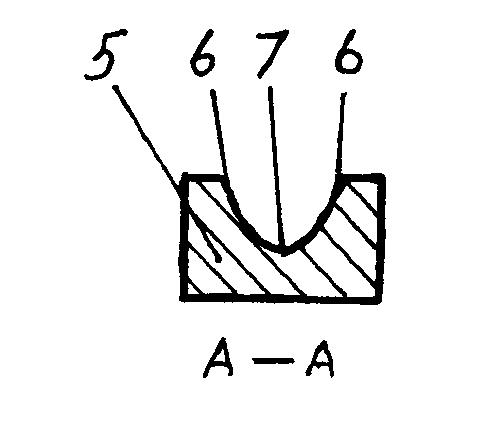

[0035] figure 1 , figure 2 Among them, the new yarn tension control device for dyeing includes a yarn guide groove 5, and the bottom 7 of the yarn guide groove 5 presents an upwardly convex curve along the length direction of the yarn guide groove 5, and the upward direction is formed by the bottom of the yarn guide groove 5. 7 points to the direction of the notch 6 of the yarn guide groove 5, and the airflow driving device 1 is installed above the yarn guide groove 5. The air flow driving device 1 is a gas nozzle, the gas output end of the air flow driving device 1 is equipped with a guide cover 3, and two relative guide holes 4 are opened radially on the wall of the guide cover 3, and the guide groove 5 is installed in the On the guide cover 3, and the yarn guide groove 5 passes through the yarn guide hole 4. The airflow driving device 1 is communicated with the air source through the automatic valve 2 (the air source is not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com