Investment-saving ammonia synthesis process and device

A technology of ammonia synthesis and ammonia synthesis tower, which is applied in the field of ammonia synthesis, can solve the problems of rising equipment investment and high equipment cost, and achieve the effect of lower design temperature and lower investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

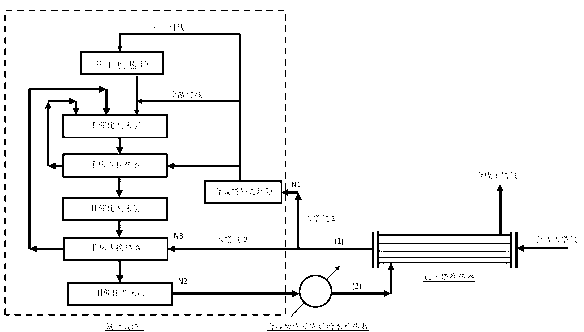

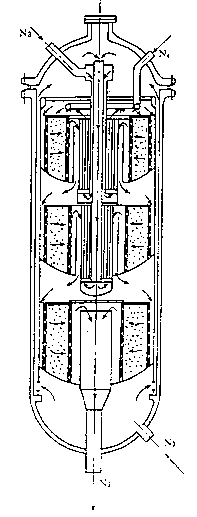

[0032] Such as image 3As shown, an ammonia synthesis process that saves investment includes an internal heat exchange ammonia synthesis tower, and its inlet and outlet heat exchange devices (inlet and outlet tower heat exchangers). The synthesis tower enters the tower gas and synthesizes the tower gas to exchange heat. The synthetic gas entering the tower passes through the tube side of the import and export heat exchange device, and the synthesized tower gas passes through the shell side of the import and export heat exchange device. The tube sheet and the tube box are separated, the tube side is connected through the tube box, and the shell side is connected through the connecting pipe. The outlet of the low temperature section is set on the tube box connecting the tube side of the low temperature section and the high temperature section, and a part of the synthetic gas entering the tower is exchanged from the inlet and outlet. The outlet of the low-temperature section of ...

Embodiment 2

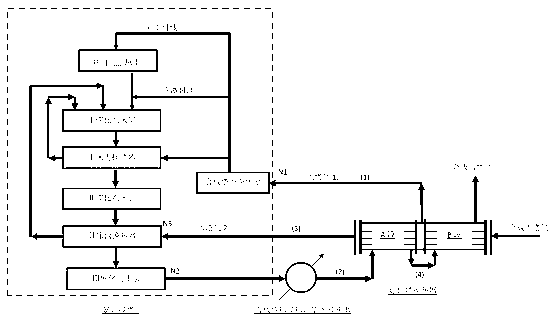

[0038] An investment-saving ammonia synthesis device, comprising an internal heat exchange type ammonia synthesis tower, and its inlet and outlet heat exchangers, the inlet and outlet heat exchangers are respectively provided with synthesis tower gas inlet and outlet and synthesis tower gas inlet and outlet, The synthetic gas entering the tower passes through the shell side of the import and export heat exchanger, and the synthesized tower gas passes through the tube side of the import and export heat exchanger. The inlet of the synthesized tower gas is connected with the outlet of the synthesized tower gas of the internal heat exchange ammonia synthesis tower, There are two outlets for the synthetic gas entering the tower at the shell side of the import and export heat exchanger, which are the outlet of the high temperature section and the outlet of the low temperature section. The outlet of the high temperature section of the internal heat exchange ammonia synthesis tower is ...

Embodiment 3

[0043] This embodiment is basically the same as Embodiments 1 and 2. The inlet and outlet heat exchangers are divided into a low-temperature section and a high-temperature section. The low-temperature section and the high-temperature section are separated by a tube sheet and a tube box. The tank is connected, and the shell side is connected through a connecting pipe. The difference is that the synthesized gas enters the tower through the shell side of the inlet and outlet heat exchangers, the synthesized tower gas passes through the tube side of the inlet and outlet heat exchangers, and the outlet of the low temperature section is set on the connecting pipe connecting the shell side of the low temperature section and the high temperature section.

[0044] Such as Figure 6 Shown: The tube side of the inlet and outlet heat exchangers is designed as two sections A and B, and the two sections are separated by different tube sheets. Section A and section B can adopt different des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com