Preparation method for composite microbial fertilizer with bioleached sludge and composite microbial fertilizer

A compound microbial fertilizer and bioleaching technology, which is applied in the direction of sewage/sludge fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of fermentation materials such as cohesion and refractory degradation, achieve good nutrient supply capacity, reduce Fermentation cost, the effect of both stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

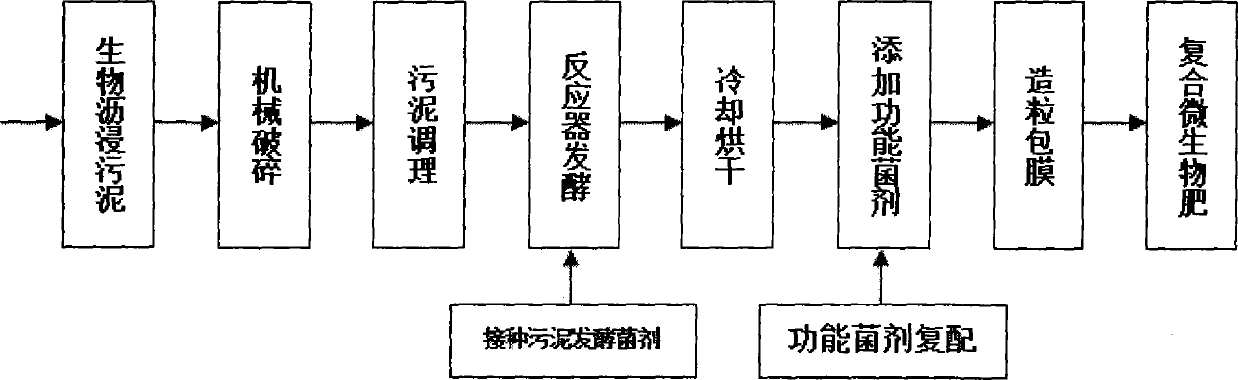

Image

Examples

Embodiment 1

[0031] Embodiment 1 has the following steps:

[0032] A. Mechanical crushing: use a crusher to pulverize the bioleaching sludge with a moisture content of 50%, the particle size of the pulverized bioleaching sludge is less than 5.0mm, and the organic matter content in the bioleaching sludge is 30%;

[0033] B. Sludge conditioning: add lime according to 0.8% of the dry weight of the above-mentioned bioleaching sludge, and adjust the pH value of the bioleaching sludge to 5.0; meanwhile, add auxiliary materials according to 4% of the wet weight of the bioleaching sludge, The auxiliary material for adjusting the porosity is a mixture of straw and mushroom slag, and the porosity of the bioleaching sludge is adjusted to 55%, and the conditioned bioleaching sludge is used as a fermentation raw material, and the organic matter content of the above fermentation raw material is controlled at 30%;

[0034] C. Reactor fermentation: inoculate the sludge fermentation agent according to 1.5‰...

Embodiment 2

[0038] Embodiment 2 has the following steps:

[0039] A. Mechanical crushing: use a crusher to pulverize the bioleaching sludge with a water content of 60%, the particle size of the pulverized bioleaching sludge is less than 5.0mm, and the organic matter content in the bioleaching sludge is 60%;

[0040]B. Sludge conditioning: add lime according to 1.2% of the dry weight of the above-mentioned bioleaching sludge, and adjust the pH value of the bioleaching sludge to 6.0; meanwhile, add auxiliary materials according to 6% of the wet weight of the bioleaching sludge, The auxiliary material for adjusting the porosity is a mixture of straw and mushroom slag, and the porosity of the bioleaching sludge is adjusted to 65%, and the conditioned bioleaching sludge is used as a fermentation raw material, and the organic matter content of the above fermentation raw material is controlled at 60%;

[0041] C. Reactor fermentation: inoculate the sludge fermentation agent according to 1.5‰ of ...

Embodiment 3

[0045] Embodiment 3 has the following steps:

[0046] A. Mechanical crushing: use a crusher to pulverize the bioleaching sludge with a moisture content of 55%, the particle size of the pulverized bioleaching sludge is less than 5.0mm, and the organic matter content in the bioleaching sludge is 45%;

[0047] B. Sludge conditioning: add lime according to 1.0% of the dry weight of the above-mentioned bioleaching sludge, and adjust the pH value of the bioleaching sludge to 5.5; meanwhile, add auxiliary materials according to 5% of the wet weight of the bioleaching sludge, The auxiliary material for adjusting the porosity is a mixture of straw and mushroom slag, and the porosity of the bioleaching sludge is adjusted to 60%, and the conditioned bioleaching sludge is used as a fermentation raw material, and the organic matter content of the above fermentation raw material is controlled at 45%;

[0048] C. Reactor fermentation: inoculate the sludge fermentation agent according to 1.5‰...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com