Gas producer deslagging device

A gasifier and slag pan technology, which is applied in the manufacture of combustible gas and the petroleum industry, can solve the problems of increased power requirements for driving the slag pan, increased equipment failure rate, and inability to drive the slag pan, so as to prevent uneven coal seam burn-through , reduce equipment failure, and prevent the effect of accumulating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

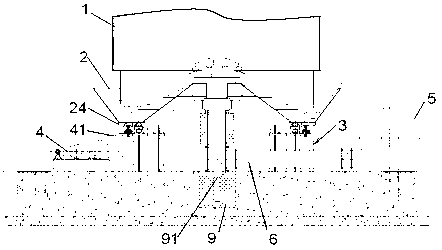

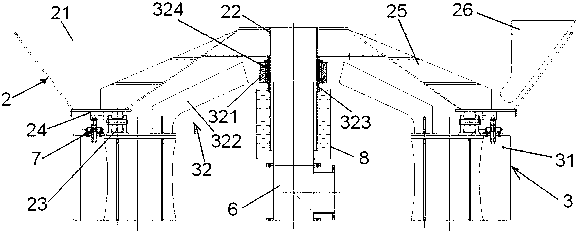

[0020] The features and performances of the present invention will be further described below in conjunction with the accompanying drawings and examples.

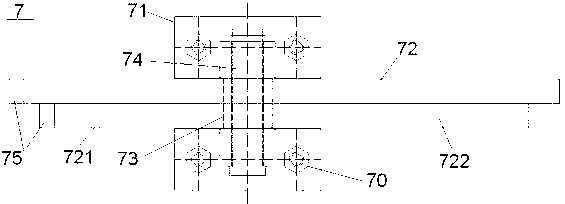

[0021] see figure 1 and figure 2 . The gas generator slagging device of the present invention comprises a slag pan 2 arranged at the bottom of the generator body 1, a support part 3 arranged at the bottom of the slag pan for supporting the slag pan, a driving part 4 for driving the slag pan to rotate, and The air duct 6 connected with the blower fan 5. The output shaft of the driving part 4 is connected with a push rod 41 . The slag pan 2 includes a disc body 21, a rotating sleeve 22 arranged at the bottom of the disc body, a supporting wheel 23, and a circle of limit teeth 24. The slag pan is also provided with a loose slag scraper 25 and a slag discharge plate. Ash knife 26; the rotating sleeve is located at the center of the bottom of the disk body, and is set on the upper part of the air duct; the supporting runner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com