Connection device of backrest wheel and nylon bar

A connecting device, nylon rod technology, applied in rigid shaft couplings, mechanical equipment, couplings, etc., can solve the problems of poor workmanship, high noise, short life, etc., to improve the start-up rate, ensure safety, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

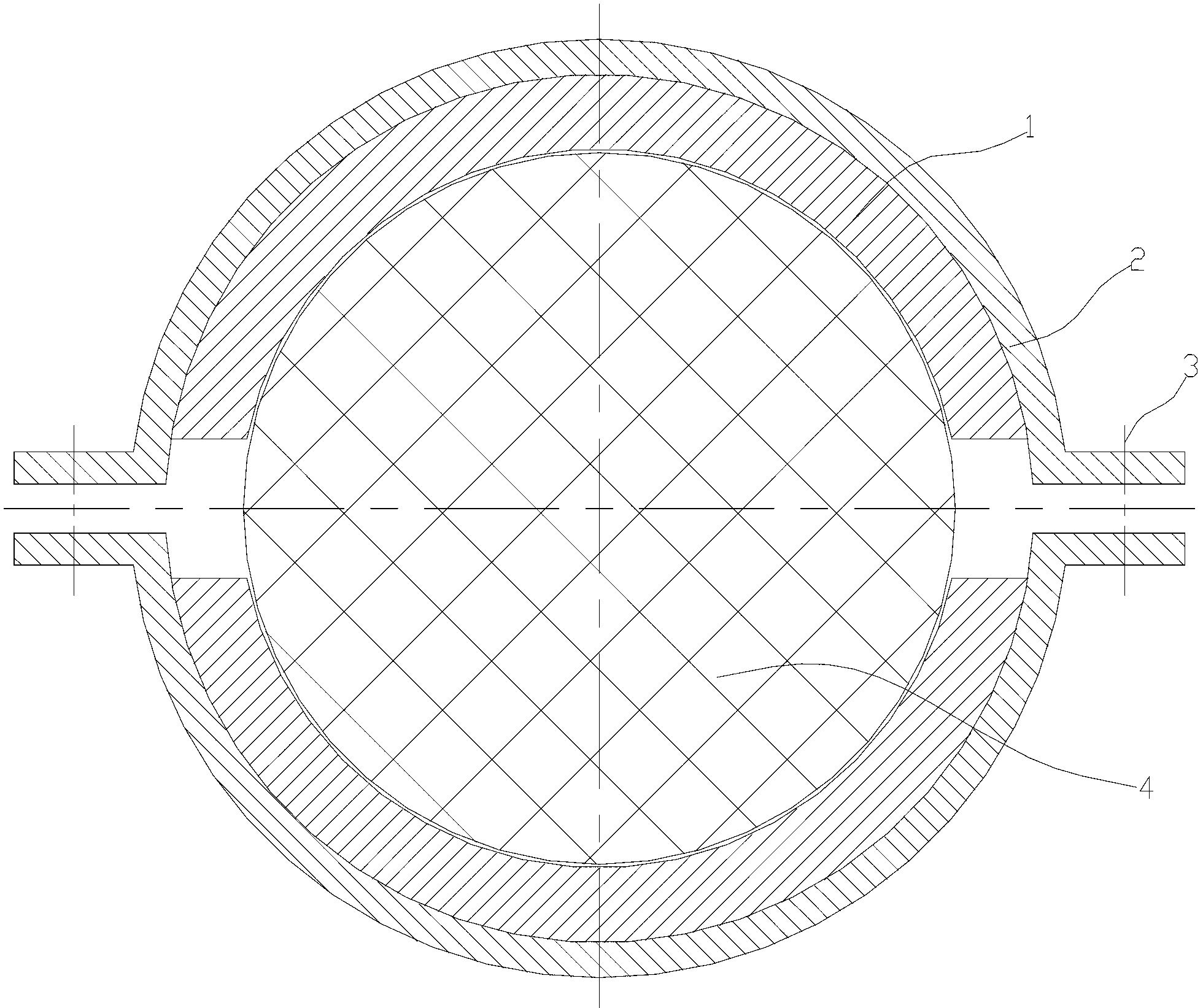

[0011] attached figure 1 It is a kind of backrest wheel nylon rod connecting device according to the present invention, comprising two half-wheel bodies 1, nylon rod 4, and said nylon rod 4 is arranged in the circular hole surrounded by two half-wheel bodies 1, and said two half-wheel bodies Blocking plates 2 are sheathed on the periphery of the body 1 ; the blocking plates 2 are connected together by screws 3 . When installing, put the blocking plate 2 on the back wheel, and then use four screws 3 to connect it as a whole. Through the screws 3, you can adjust the tightness of the device and adjust the force of the nylon rod 4. With the running of the back wheel, the blockage is achieved. The purpose of the nylon rod 4 is to completely solve the problem of broken screws of the original blocking board, reduce the labor intensity of the workers, improve the operating rate of the belt con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap