A water level automatic control float valve

A floating ball valve, water level technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of water accumulation in the water tank, dust endangering the health of operators, increasing the use of mines and saving capital, etc., to achieve the effect of reliable and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

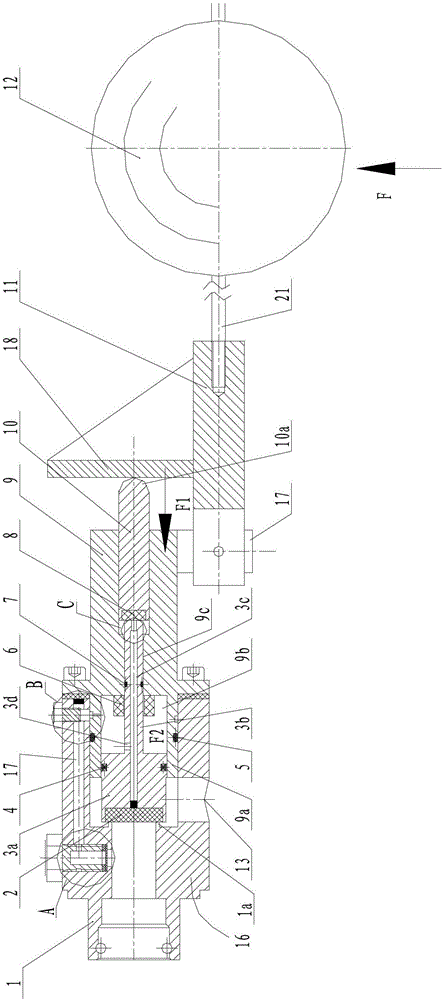

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

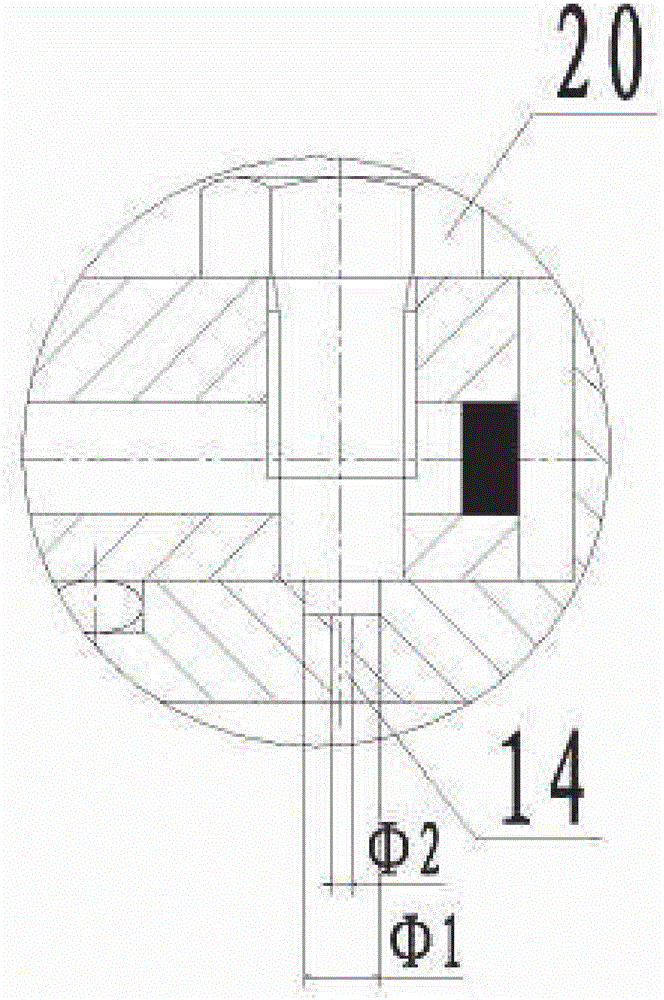

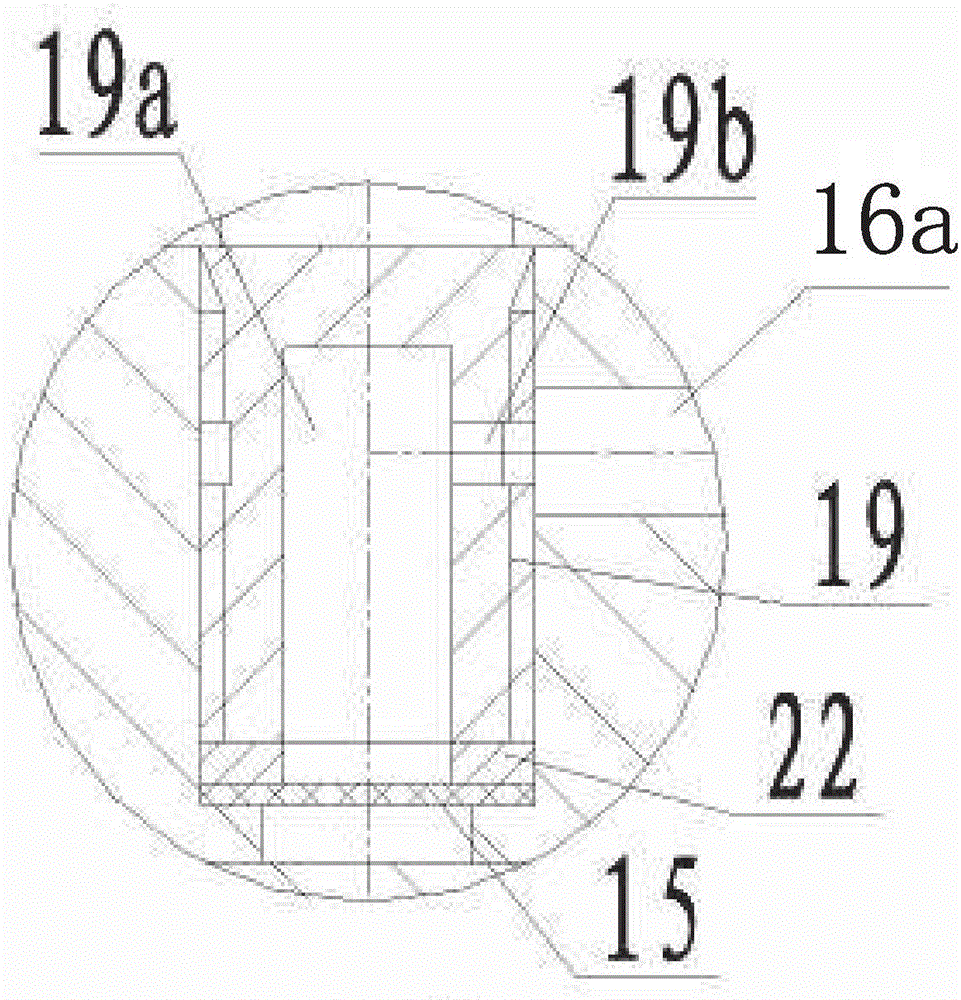

[0027] like Figure 1 to Figure 4 As shown, a float valve with automatic water level control includes a valve body 16, on which a water inlet 1 and a water outlet 13 intersecting each other are arranged, and a flange 1a is arranged at the end of the water inlet 1.

[0028] Valve body 16 is fixed with piston seat 9 relative to the far end of water inlet 1, and one end of piston seat 9 stretches in the valve body 16, and this protruding end 9a is set as piston chamber 9b, is provided with piston body 3a in piston chamber 9b, and piston The end surface of the body 3a can block the water inlet 1, and the cylindrical surface can block the water outlet 13. The bottom of the piston chamber 9b is fixed with a limit sleeve 6 .

[0029] The valve body 16 is provided with a flow channel 16a which can communicate with the water inlet 1 and the piston cavity 9b, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com