Basin faucet

A faucet and washbasin technology, applied in valve details, engine components, valve housing structure, etc., can solve problems such as failure to achieve normal water discharge, achieve high practical value and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

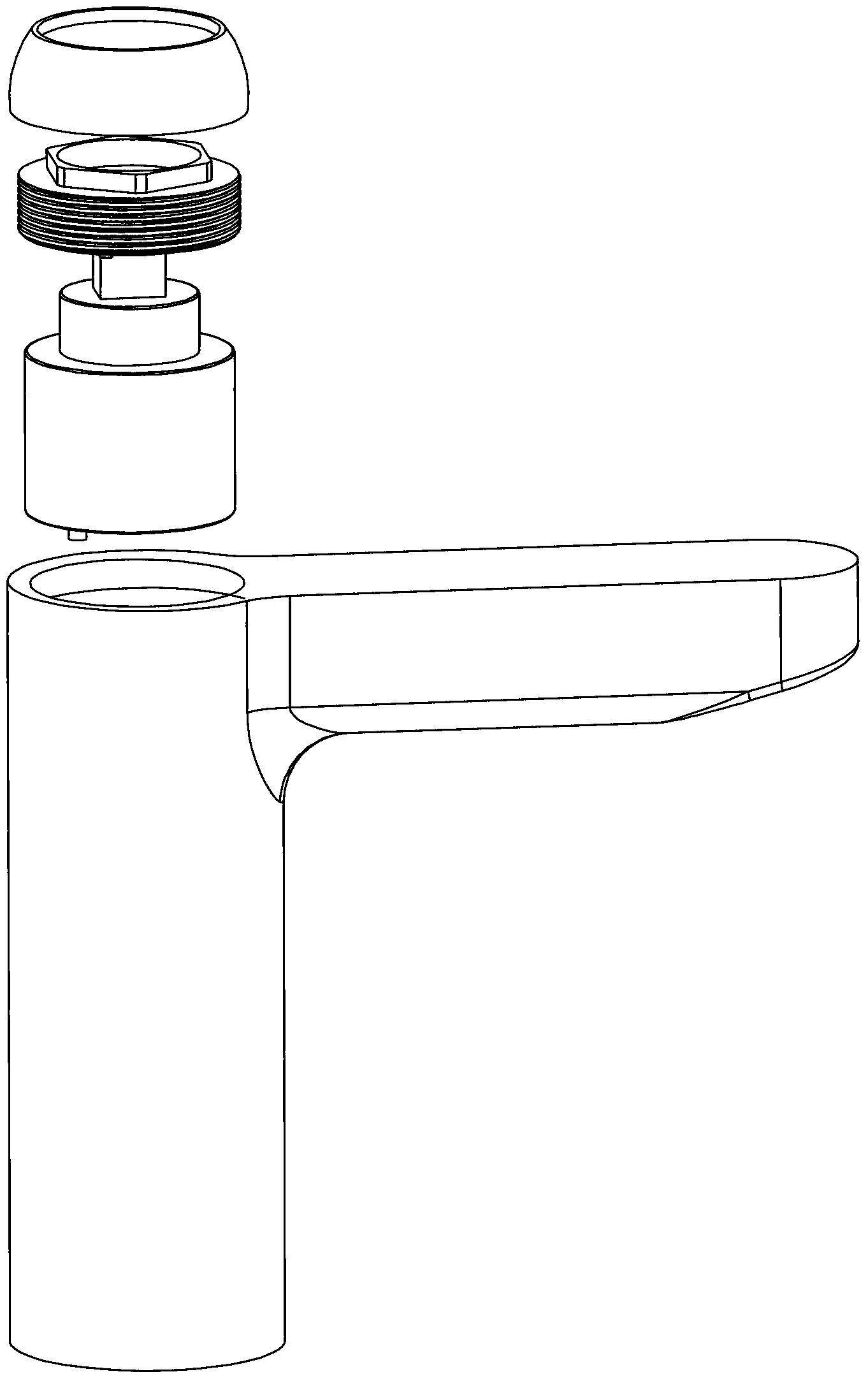

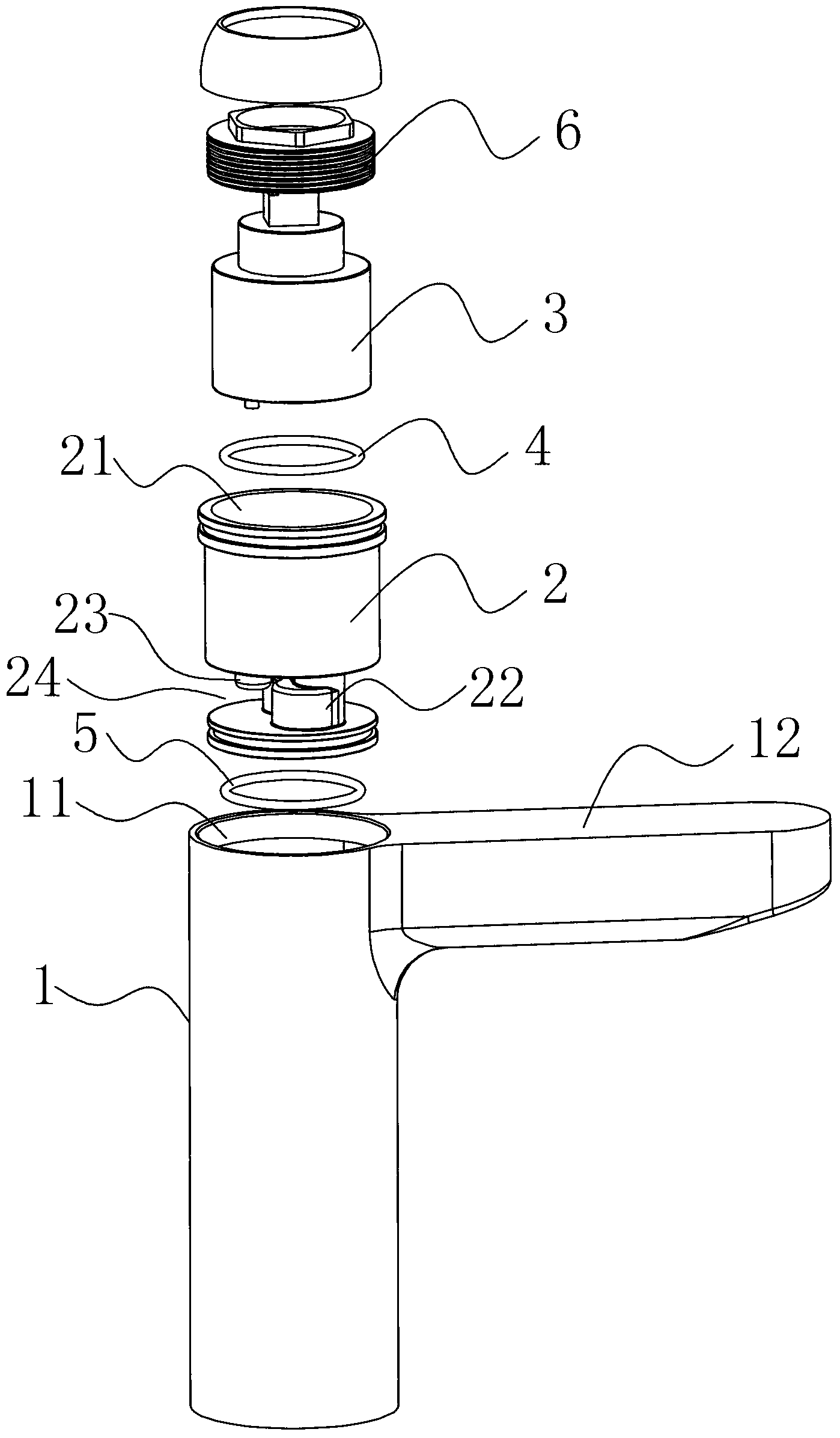

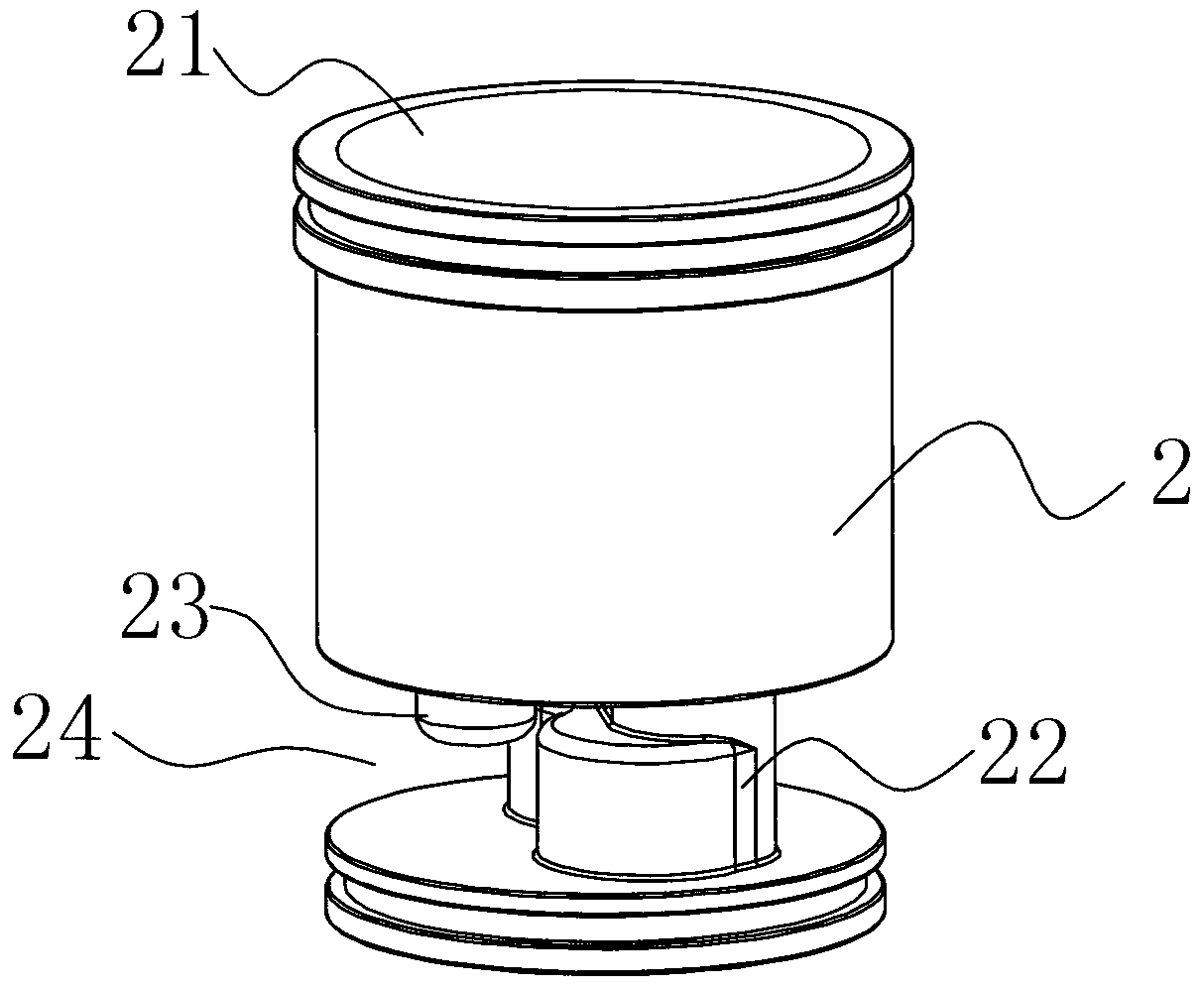

[0014] refer to Figure 2 to Figure 3 , a basin faucet of the present invention, comprising a faucet main body 1, the faucet main body 1 is provided with an installation chamber 11 for accommodating a valve core and a spout 12 for water outlet, the installation chamber 11 of the faucet main body 1 is provided with There is a valve seat 2 with an inner cavity 21, a flat foot valve core 3 installed in the inner cavity 21 of the valve seat 2 to adjust the water outlet, and an upper cover 6 fixed with the main body 1 of the faucet.

[0015] The bottom of the valve seat 2 is provided with a water diversion pipe 22 communicating with the water inlet pipe to introduce water flow into the inner cavity 21, and a water outlet 23 connecting the inner cavity 21 and the outside is arranged beside the water diversion pipe 22. When the valve seat 2 is installed on the main body of the faucet 1 in the installation cavity 11, the water outlet 23 communicates with the water outlet 12 through th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap