Cable-free type pipeline countercurrent crawl device

A crawler and cable-free technology, which is applied to special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of high cost, restrictions on long-distance operation of pipeline crawlers, and limited electric power of built-in batteries, etc., to achieve Reduce unnecessary operations, reduce testing and maintenance costs, and save supporting facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

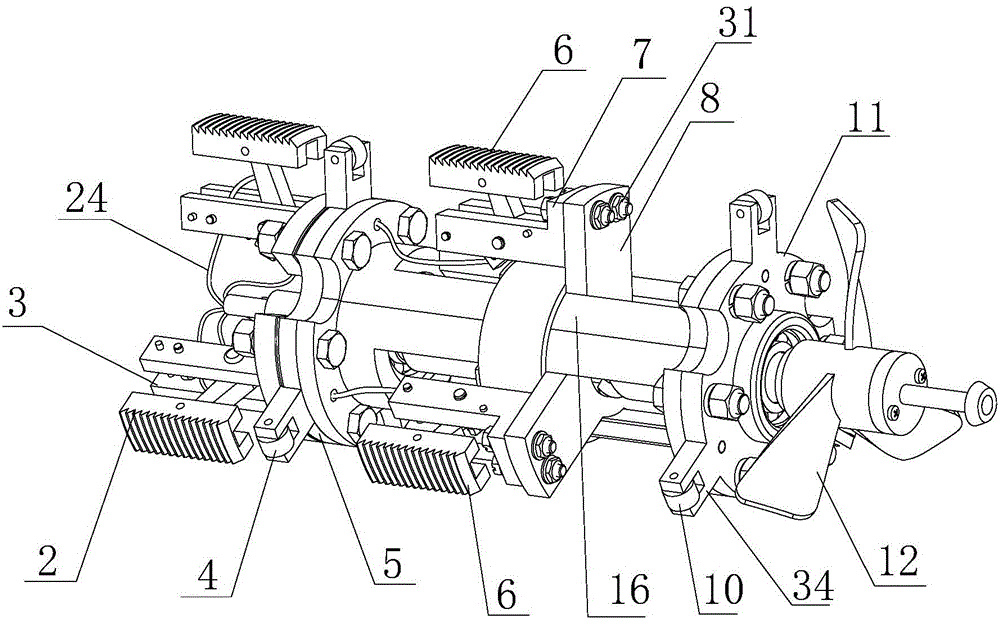

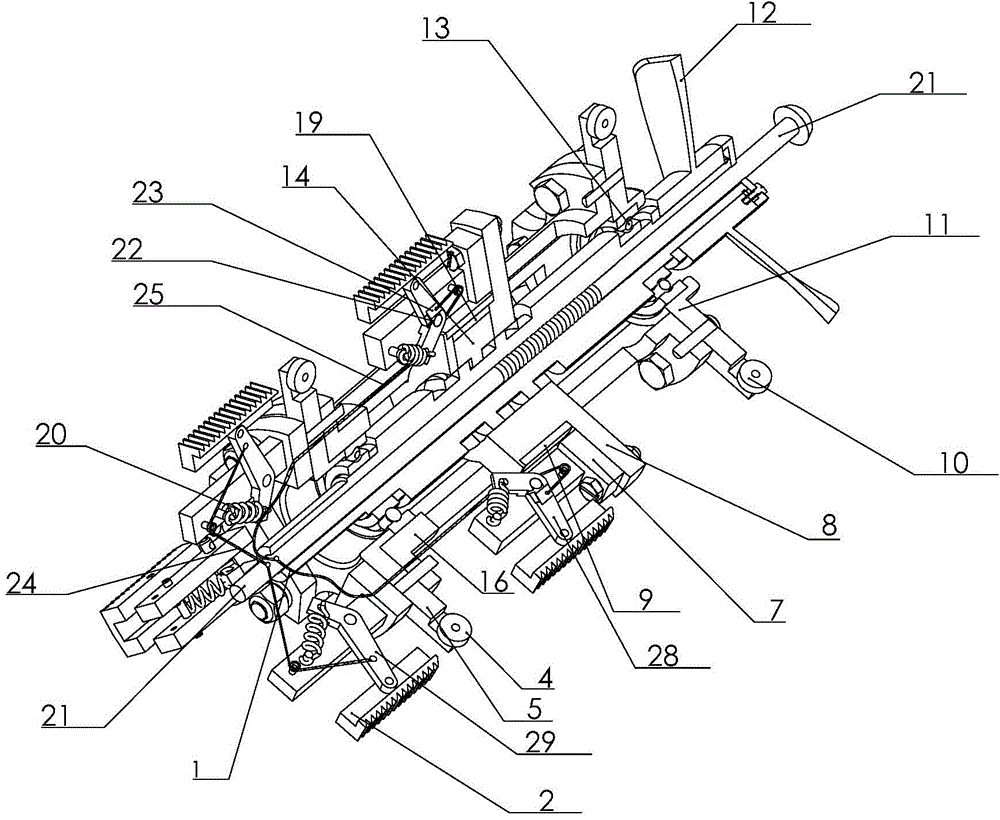

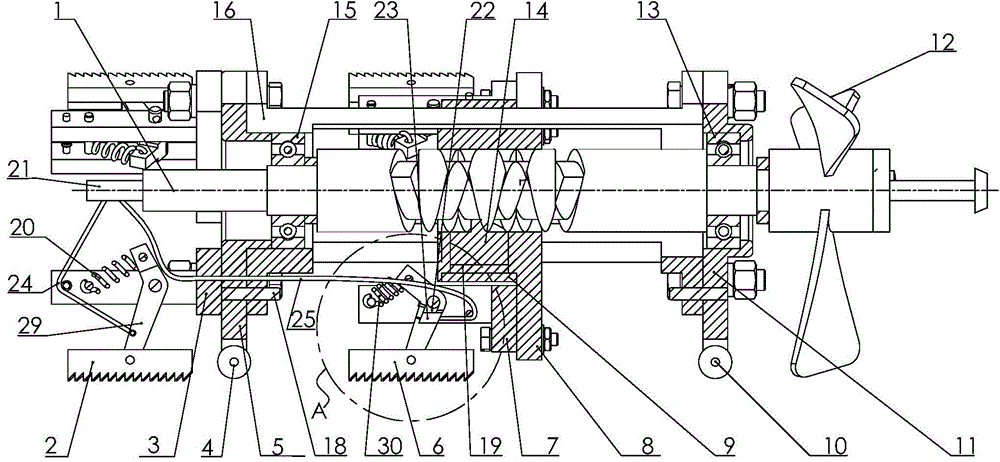

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0043] The cableless pipeline countercurrent crawler proposed by the present invention includes a crawling cylinder, a driving mechanism, a front slip crawling mechanism and a rear slip stop mechanism, and the front slip crawling mechanism is installed on the crawling cylinder along the axial direction. In the crawling groove, the crawling groove is connected with the inside of the crawling cylinder, and the driving mechanism runs through the crawling cylinder in the axial direction. The front slip crawling mechanism cooperates with the screw transmission of the driving mechanism, so that the front slip crawling mechanism moves back and forth along the crawling groove. In this way, the reciprocating movement of the front slip craw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com