Low-temperature gas cylinder vacuuming system

A vacuum pumping system and vacuum pumping technology, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of long pumping time, increased vacuum resistance, and differences in the vacuum degree of gas cylinders Large and other problems, to achieve the effect of improving vacuum efficiency, shortening length, and improving conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

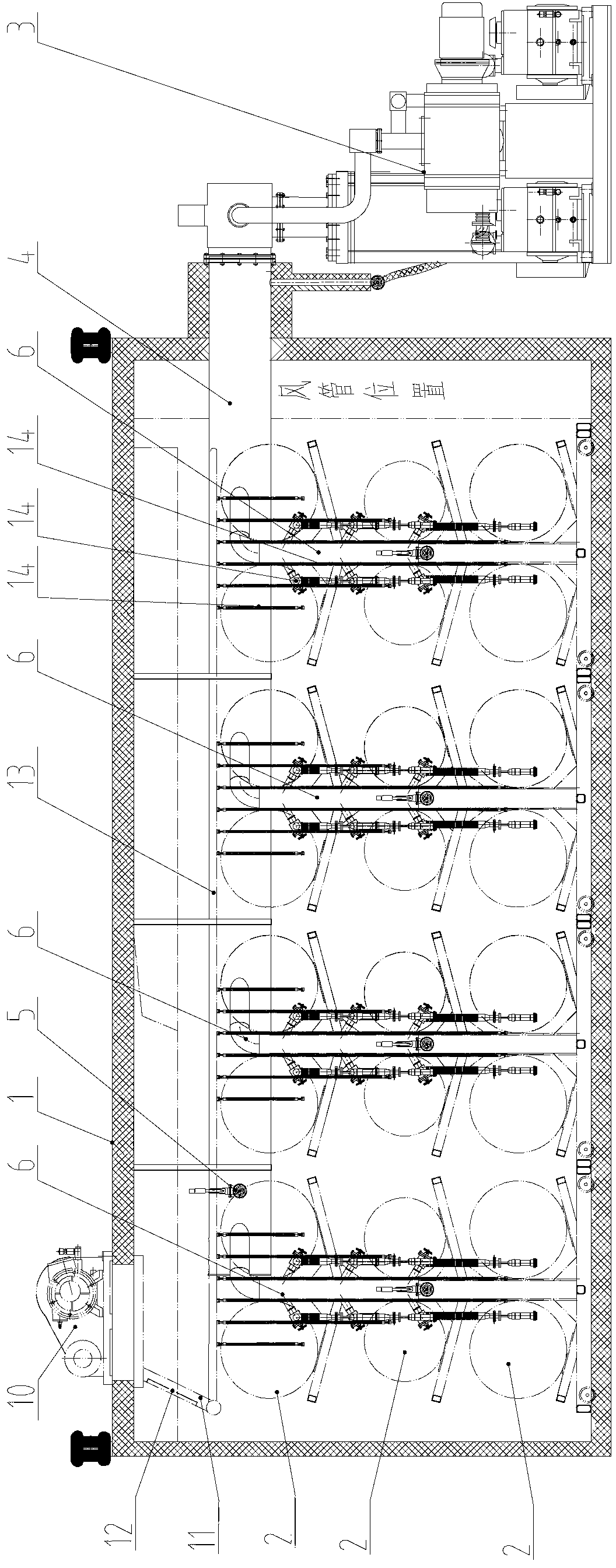

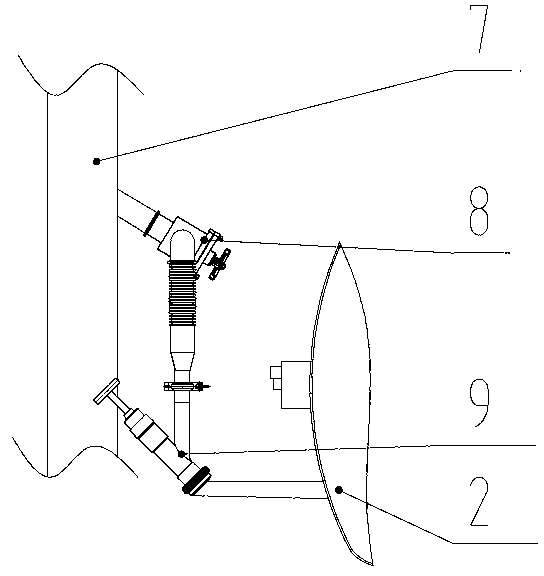

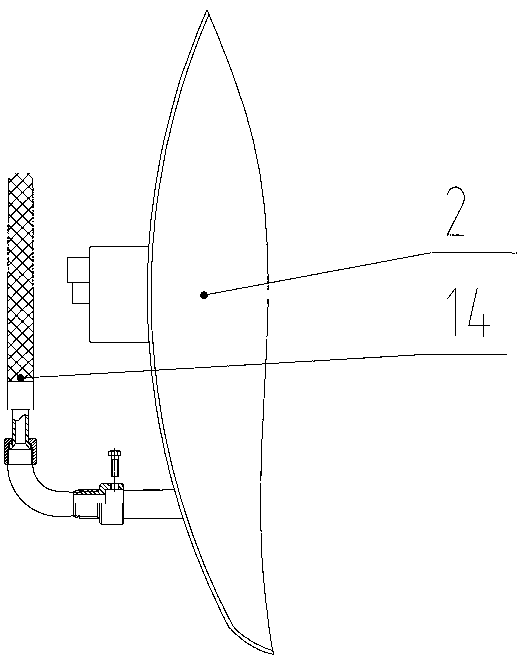

[0016] like Figure 1-3 As shown, the low-temperature gas cylinder vacuum system includes a body of furnace 1, a number of cylinders to be evacuated 2 arranged in the inner cavity of the body of furnace 1, and a vacuum unit 3 connected to the cylinder 2 to be evacuated. It is connected with the main pipe 4, and the main pipe 4 is provided with a vacuum gauge 5. The main pipe 4 is provided with 8 primary branch pipes 6, and each primary branch pipe 6 is provided with 6 secondary branch pipes 7, and the secondary branch pipes 7 are bellows. The secondary branch pipe 7 is connected to the vacuum port of the cylinder 2 to be pumped through the baffle valve 8 and the vacuum tooling 9 .

[0017] The system also includes a heating device inside the gas cylinder, including a blower 10 arranged on the furnace body 1 , the air outlet of the blower 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com