Pulverized coal furnace natural gas igniter

A technology for natural gas and igniter, which is applied to the field of natural gas igniter for pulverized coal furnace, can solve the problems of poor insulation protection effect of ignition unit, limited use of natural gas igniter, high use cost and maintenance cost, and solves the problem of ignition safety. And the effect of convenience, convenient transportation and transportation, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

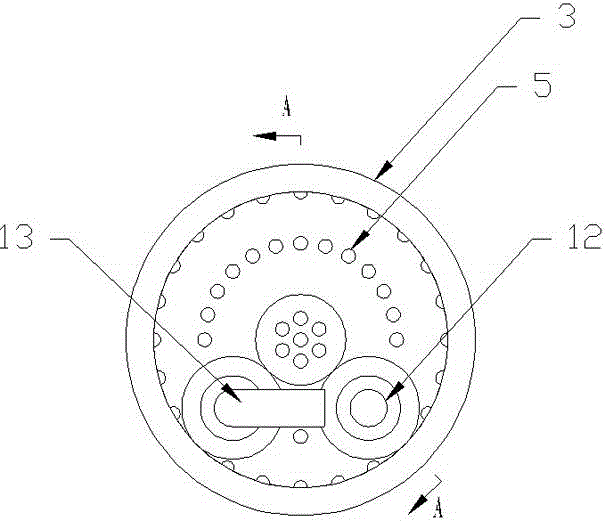

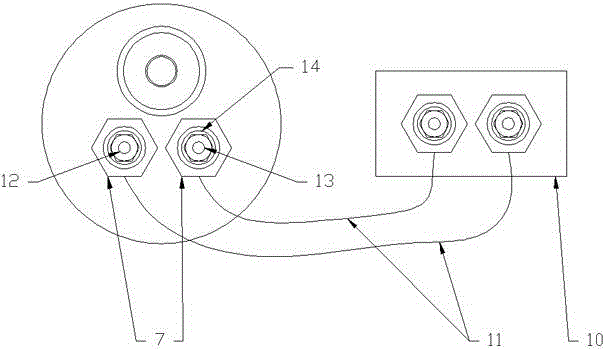

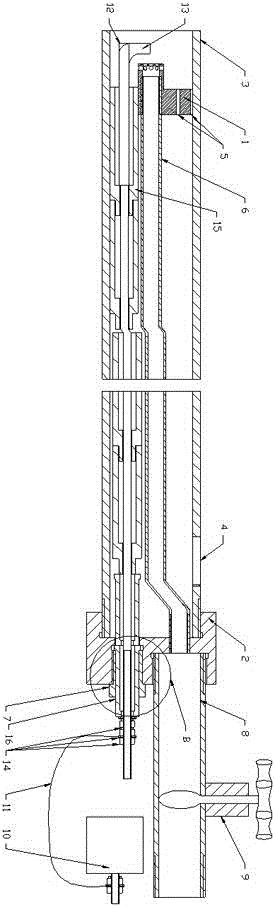

[0018] A natural gas pilot burner for pulverized coal furnace, such as figure 1 , 2 , 3, including a gas delivery unit, a DC pulse circuit unit, a front fixed end 1, a rear fixed end 2, and a hand-held protection tube 3, the hand-held protection tube is provided with a threaded air inlet 4, and the There is a vent hole 5 on the front fixed end; the gas delivery unit includes a gas pipe 6, a pressure reducing valve, a valve, a gas delivery hose, a throttle valve 9 and a gas connection pipe 8, and the gas connection pipe passes through a gas delivery soft The pipe, the pressure reducing valve and the valve are connected with the natural gas cylinder; the DC pulse circuit unit includes a DC storage pulse power supply 10, a power line 11 (positive power line and negative power line), power terminal (positive power terminal 12 and Negative power supply terminal 13) and the connection nut 14 connected with the power supply terminal are connected by the DC storage pulse power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com