Treating method of furnace roller nodule

A treatment method and technology of furnace rollers, which are applied in the field of metallurgy, can solve problems affecting the normal operation of the unit, and achieve the effects of ensuring stable production, saving energy, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

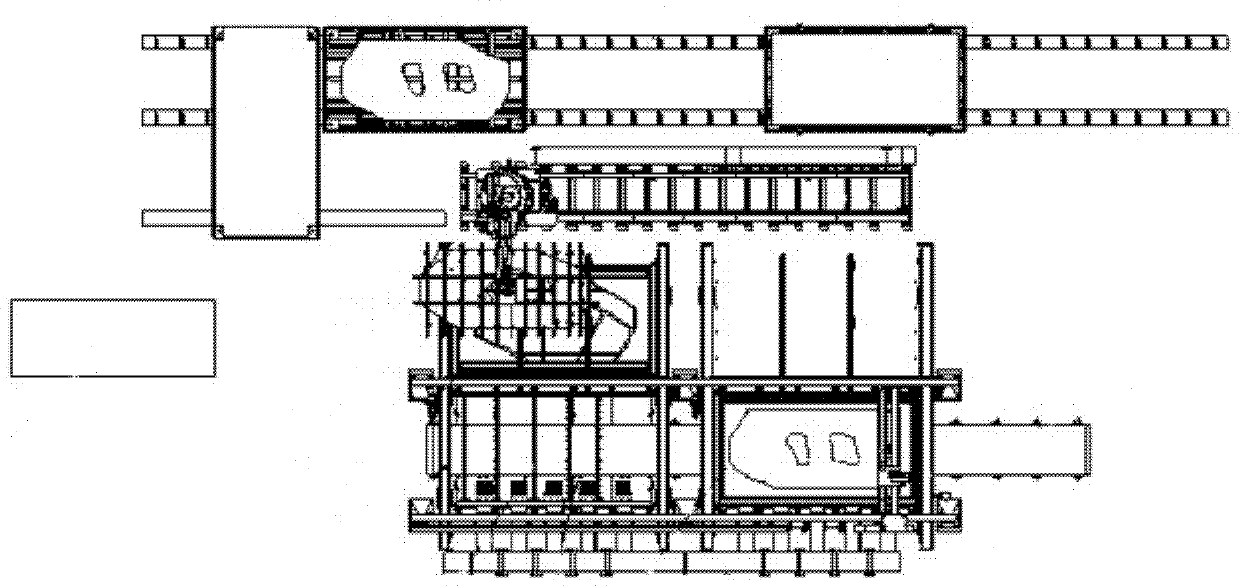

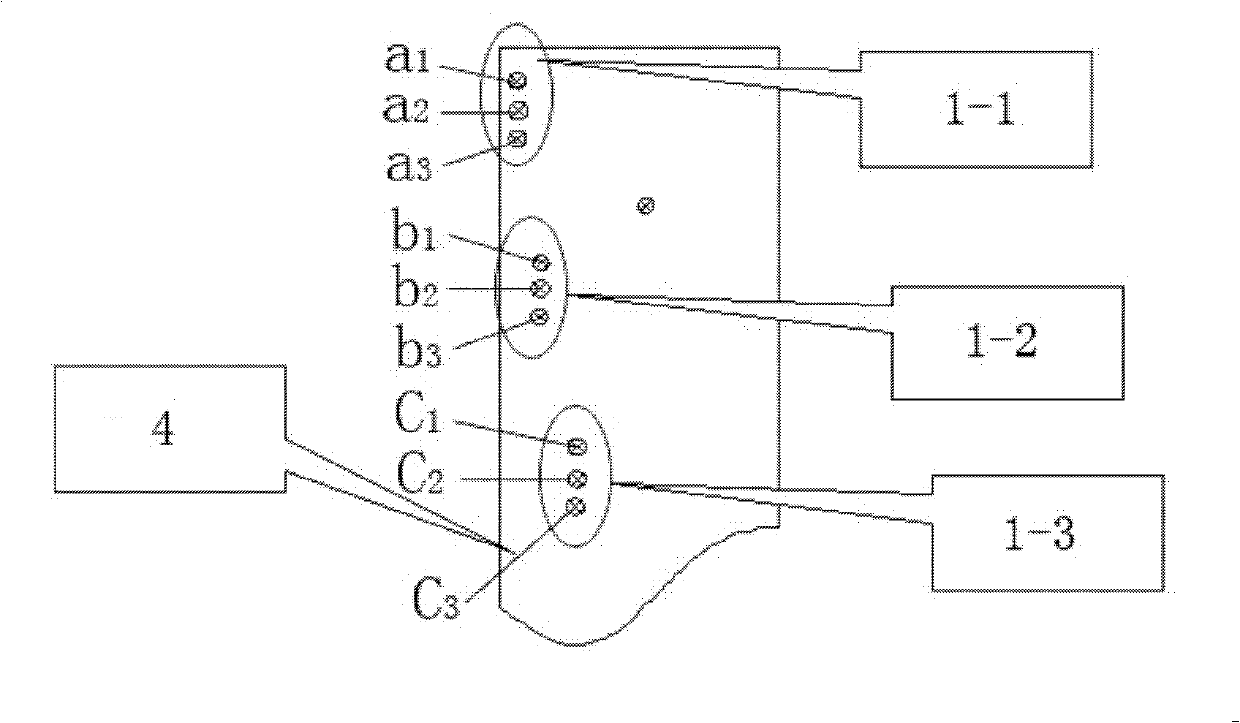

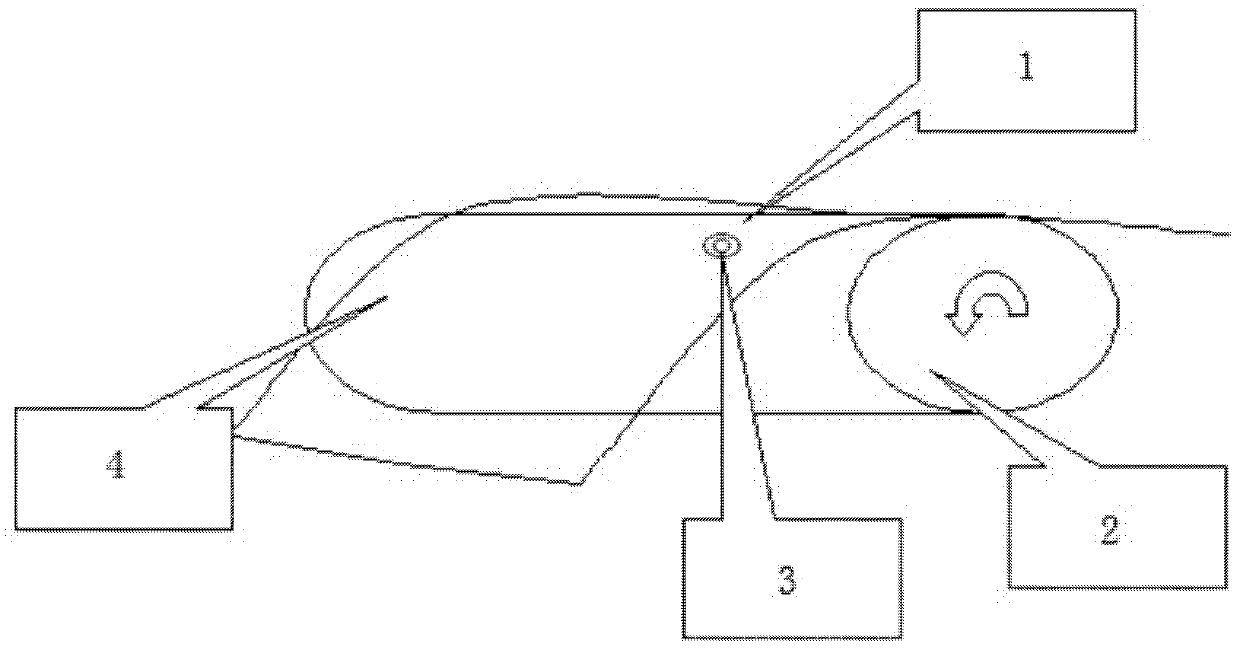

Image

Examples

Embodiment 1

[0038] A treatment method for furnace roll nodulation, said method comprising the steps of:

[0039] Make a mark at the exit of the furnace, that is, use a screwdriver to draw a line on the strip surface on the outer strip of the last stick at the exit of the annealing furnace as a mark, and determine the number of the furnace roll caused by the nodulation of the furnace roll and the number of the furnace roll in the furnace according to the grinding mark. The transverse width position on the roll. Prepare another roll of new strip steel transition volume, and described new strip steel transition volume is the electrical steel strip steel coil of the same material. Holes are punched on said new strip transition coil, the hole diameter The edges of the holes are flush with the strip, so that holes are distributed (intervals) across the width of the plate.

[0040] According to the nodulation width position reflected on the strip steel, the strip steel position corresponding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com