Spherical regenerator

A heat storage body and sphere technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as increased production costs, poor air permeability of heat storage systems, and ball-to-ball adhesion , to achieve the effect of prolonging the service life, reducing the number of ball changes and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

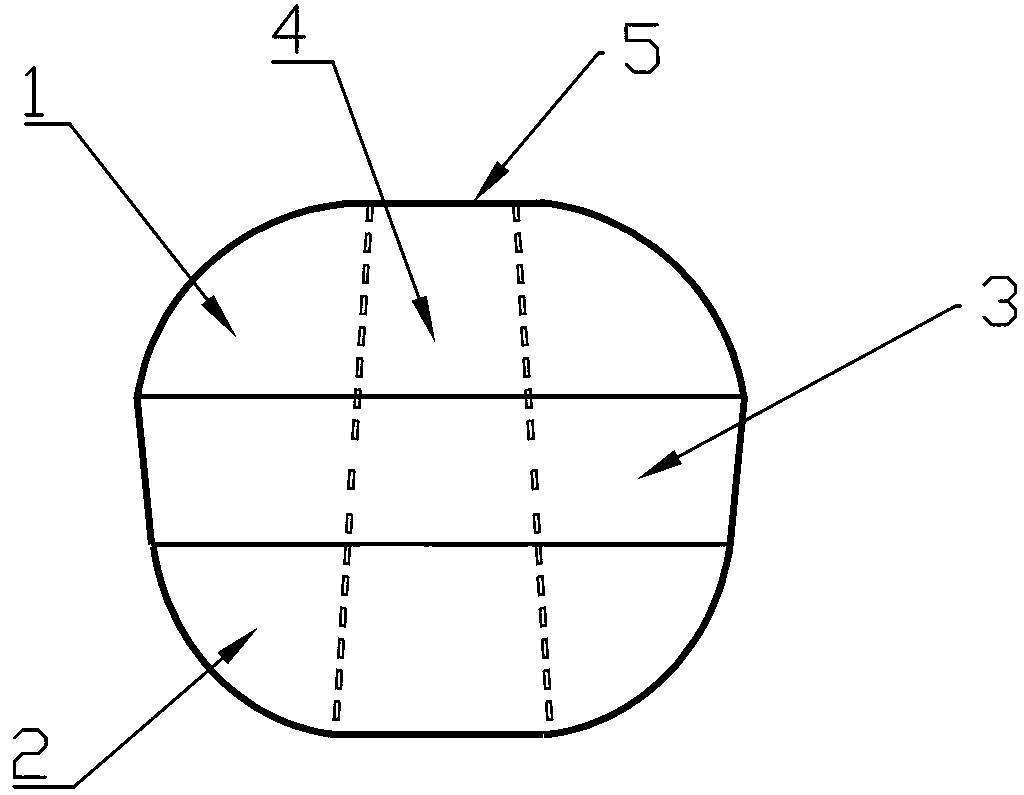

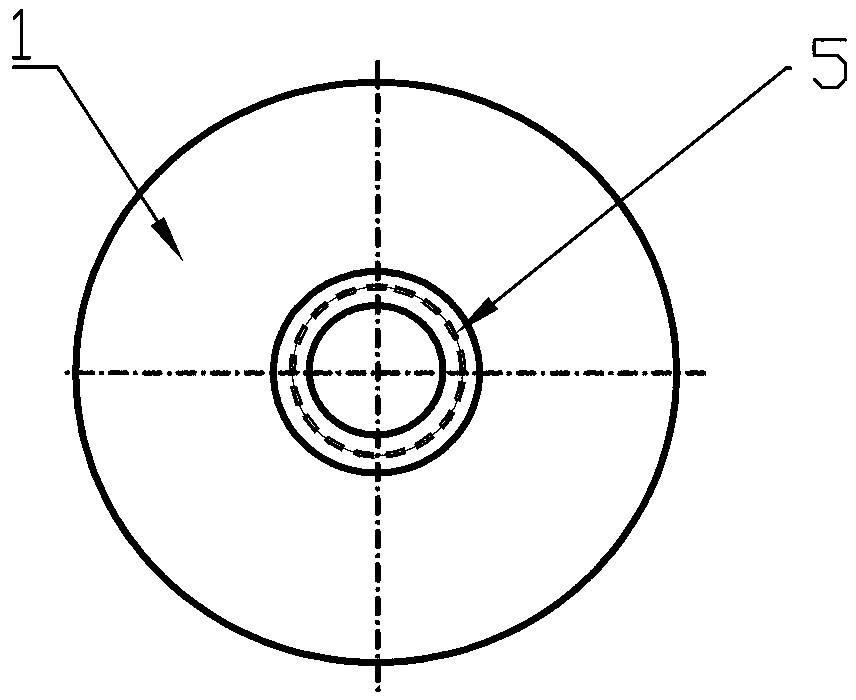

[0013] Such as figure 1 , figure 2 As shown, a spherical regenerator of the present invention includes an upper sphere 1, a lower sphere 2 and a platform section 3, and the platform section 3 is arranged between the upper sphere 1 and the lower sphere 2, and the upper sphere 1 , The center of the lower sphere 2 and the platform section 3 is provided with a central through hole 4, the central through hole 4 runs through the upper sphere 1, the lower sphere 2 and the platform section 3 along the central axis, the upper sphere 1 Both the top and the bottom of the lower sphere 2 are provided with facets 5 .

[0014] As an optimization, the central through hole 4 is a tapered central through hole with a small top and a large bottom. This design can increase the heat storage area of the spherical heat storage body, enhance the air permeability of the heat storage system, and at the same time facilitate the pressing of heat storage bodies with high mechanical compression strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com