Cable connector fault diagnosing method

A cable joint and fault diagnosis technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of limited application scope, failure to consider the transient process of cable heat capacity and temperature rise of cable joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

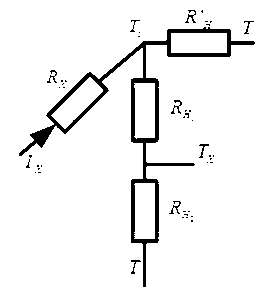

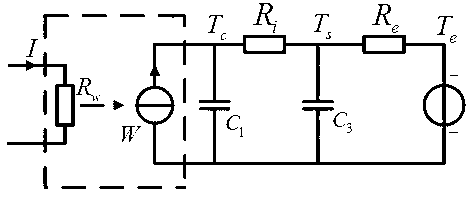

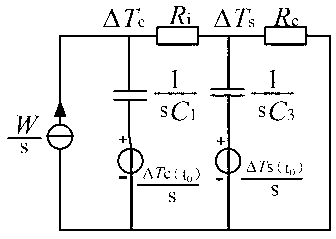

[0086] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

[0087] Step 1: Initialize the system conditions: ①Set the inner aluminum sheath of the cable joint as the monitoring point of the joint temperature, and set the outer surface temperature of the cable joint as the monitoring point of the ambient temperature ②Set the maximum fluctuation threshold m=0.2℃ in the steady state of the ambient temperature , The maximum fluctuation threshold n=50A when the cable current is in a steady state; ③Set the minimum time unit t during monitoring x =1min, the sampling interval Δt of the independent variable and the dependent variable m =11min;

[0088] Step 2: Press the set t x , real-time sampling of cable current I and monitoring point temperature T at equal intervals s and ambient temperature T e , and save the historical monitoring data to form I, T s , T e The monitoring curve about the tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com