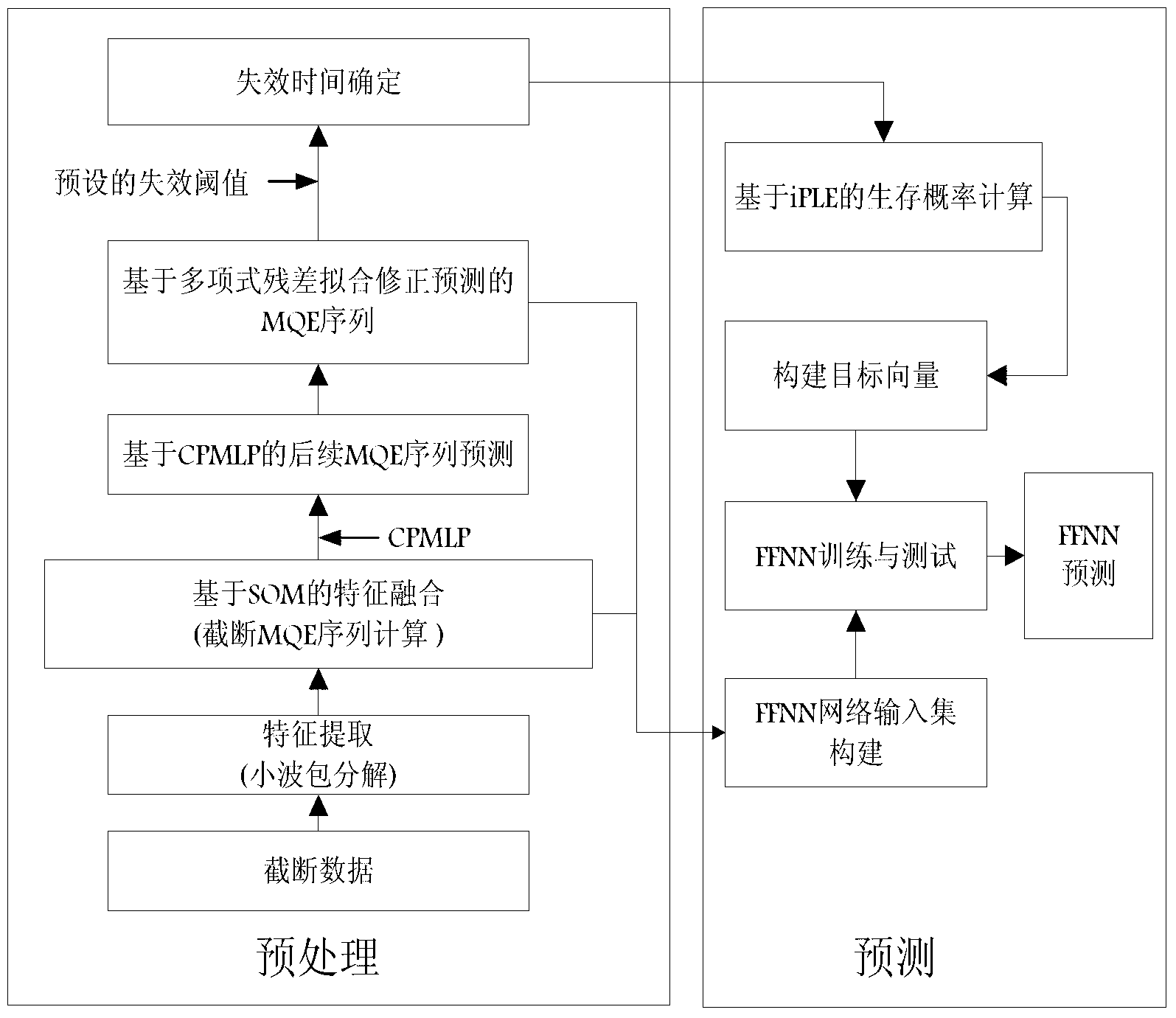

Service life prediction method for electromechanical system and critical components under completely truncated data condition

A technology for electromechanical systems and life prediction, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as performance degradation, and achieve the effect of avoiding information loss and good prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

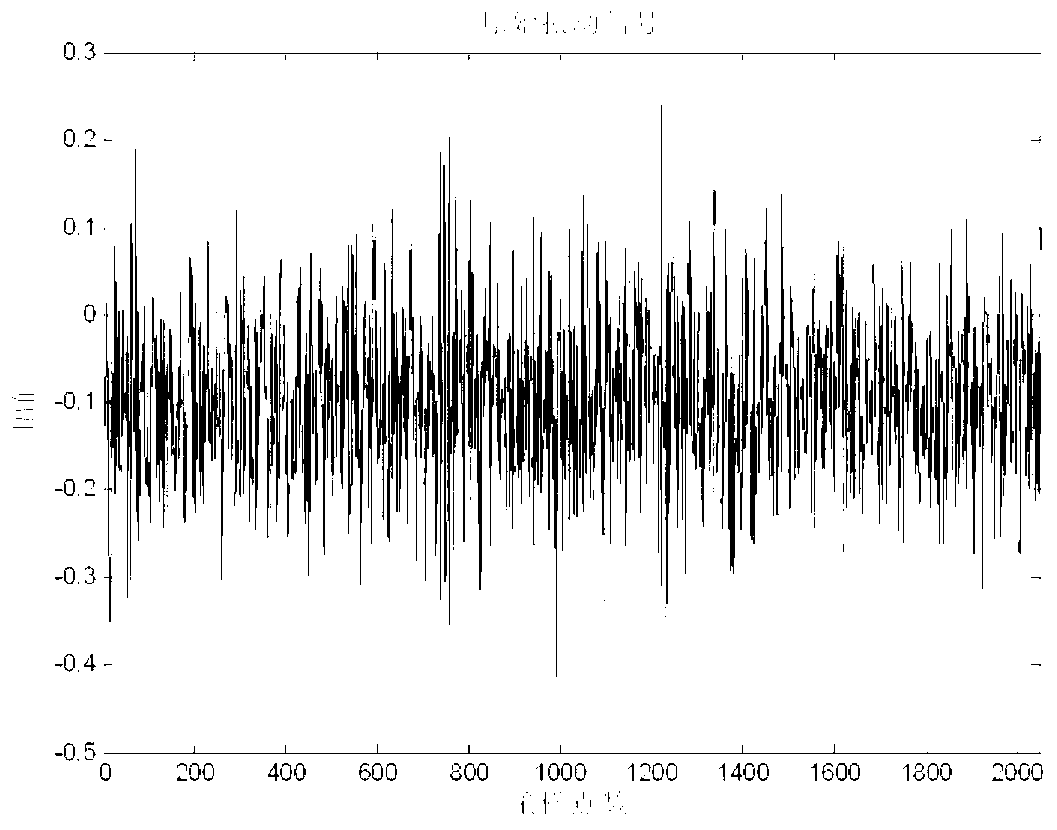

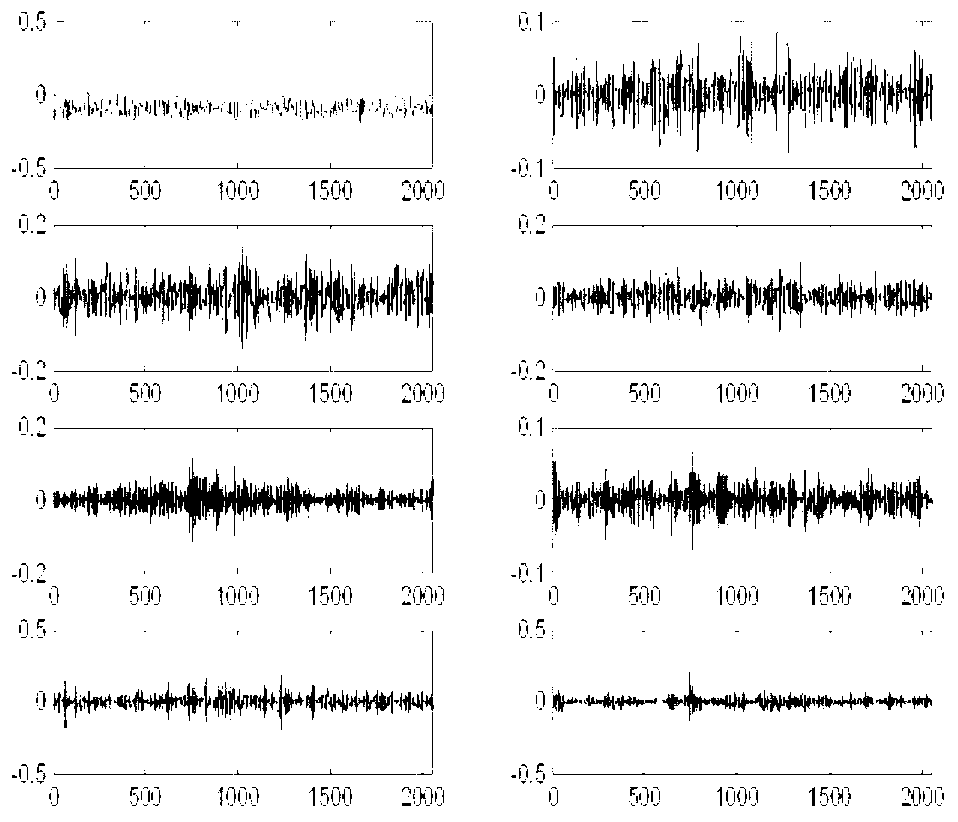

[0103] In this embodiment, 40 sets of life data of rolling bearings (original vibration signal, sampling frequency 20KHZ) are collected, among which 30 sets of data will be artificially truncated randomly to form "completely truncated data", which will be used as training data samples for the method of the present invention, as shown in Table 1 shown. The remaining 10 sets of whole-life data are used to verify the effectiveness of this method, as shown in Table 2. Through the detailed elaboration of this embodiment, the implementation process and engineering application value of the present invention are further described.

[0104] Table 1 Training sample set of forecast model

[0105]

[0106] Table 2 10 test samples

[0107] Test Sample No.

31

32

33

34

35

36

37

38

39

40

real failure time

26

14

31

32

10

20

39

15

25

34

Predicted failure time period

27

15

31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com