Fluid handling system having dedicated egr turbo-generator

A fluid treatment and turbine technology, applied in fuel heat treatment devices, charging systems, combustion air/combustion-air treatment, etc., can solve problems such as hindering the reduction of NOx and increasing the combustion temperature in the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

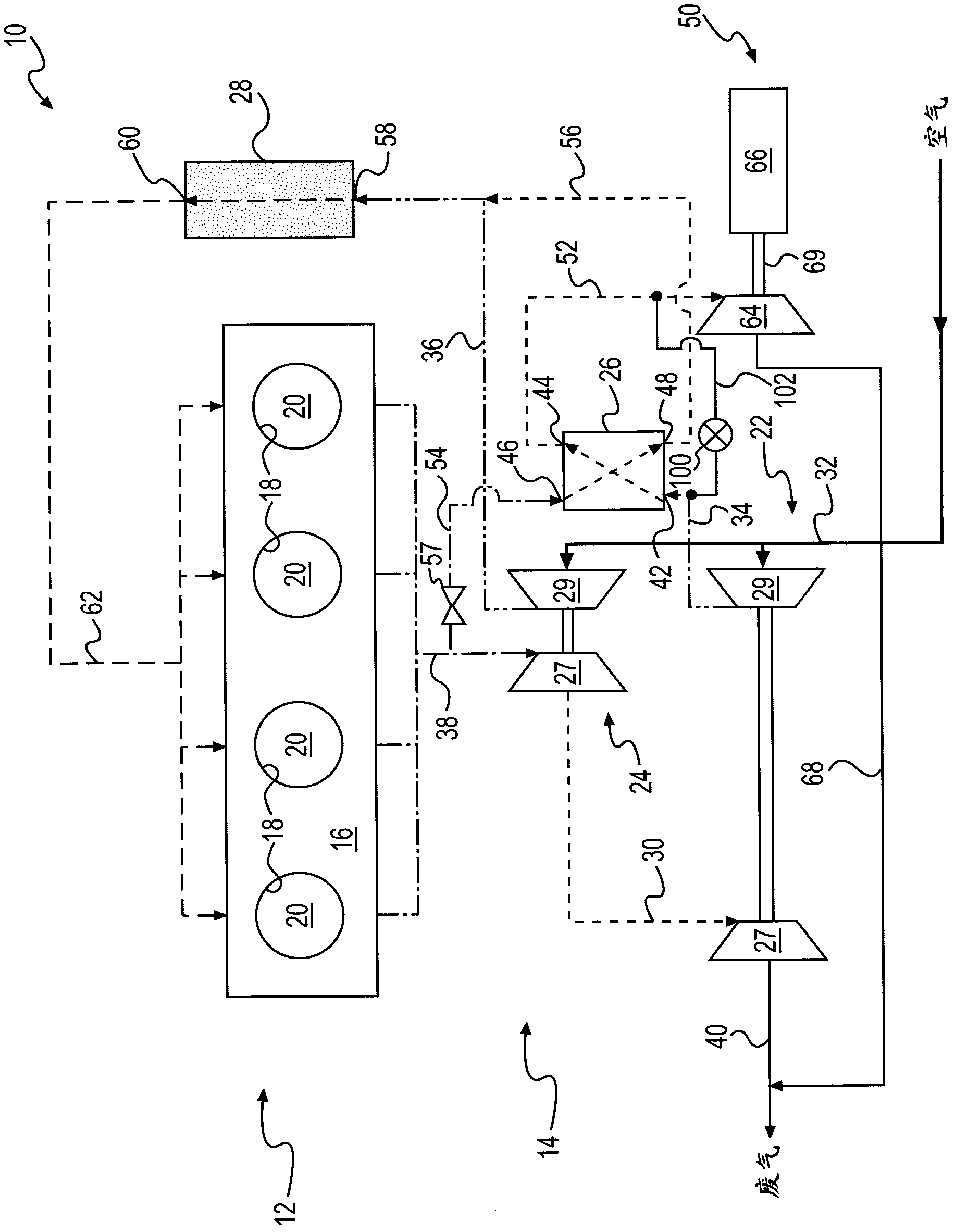

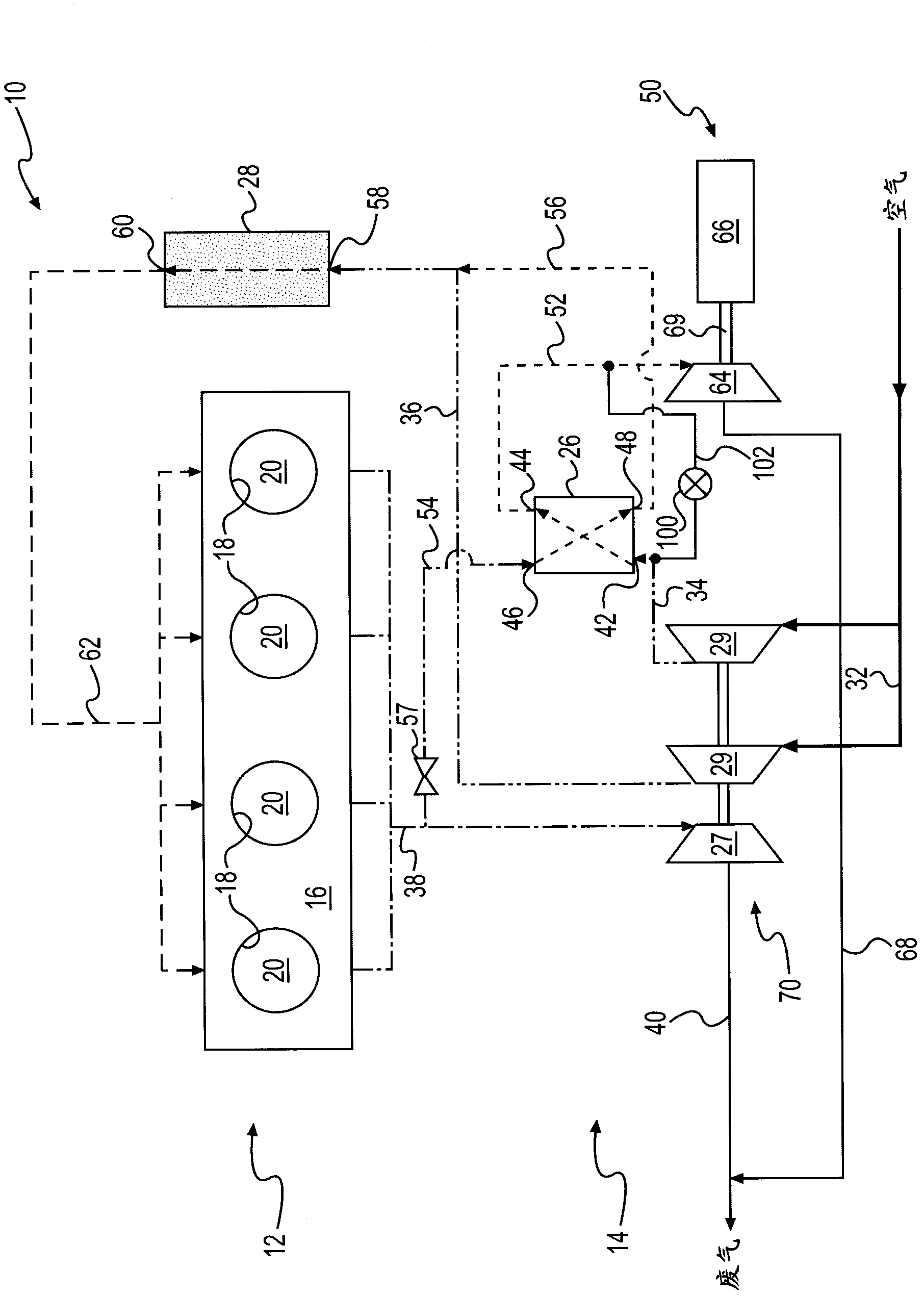

[0010] figure 1 Power system 10 is shown having power source 12 and fluid handling system 14 . For purposes of this disclosure, power source 12 is described and depicted as a four-stroke diesel engine. Those of ordinary skill in the art will recognize, however, that power source 12 may be any other type of combustion engine, such as a gasoline or gaseous fuel powered engine. Power source 12 may include an engine block 16 at least partially defining a plurality of cylinders 18 . A piston (not shown) may be slidably disposed within each cylinder 18 for reciprocating movement between a top dead center position and a bottom dead center position, and one or more cylinder heads (not shown) may be connected to the engine cylinders. body 16 to close the end of each cylinder 18. Each cylinder 18 , piston and head may together define a combustion chamber 20 . In the illustrated embodiment, power source 12 includes four such combustion chambers 20 . However, it is contemplated that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com