led drive circuit and led drive chip

An LED driver and chip technology, applied in the direction of electric lamp circuit layout, electric light source, electrical components, etc., can solve the problems of expensive components, inability to be widely used, and high working environment temperature, to suppress low-frequency output current ripple, solve the Low frequency flicker problem, high working reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

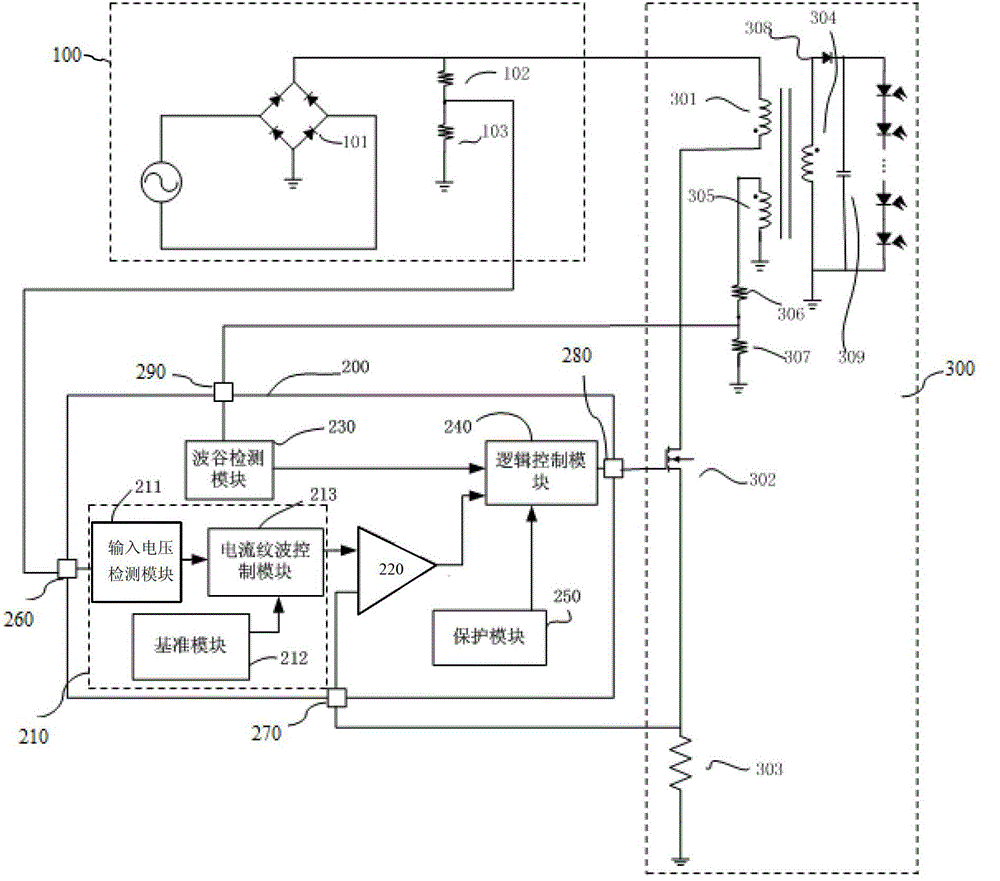

[0041] In the first embodiment of the LED driver chip of the present invention, see figure 1 , the LED driver chip 200 includes:

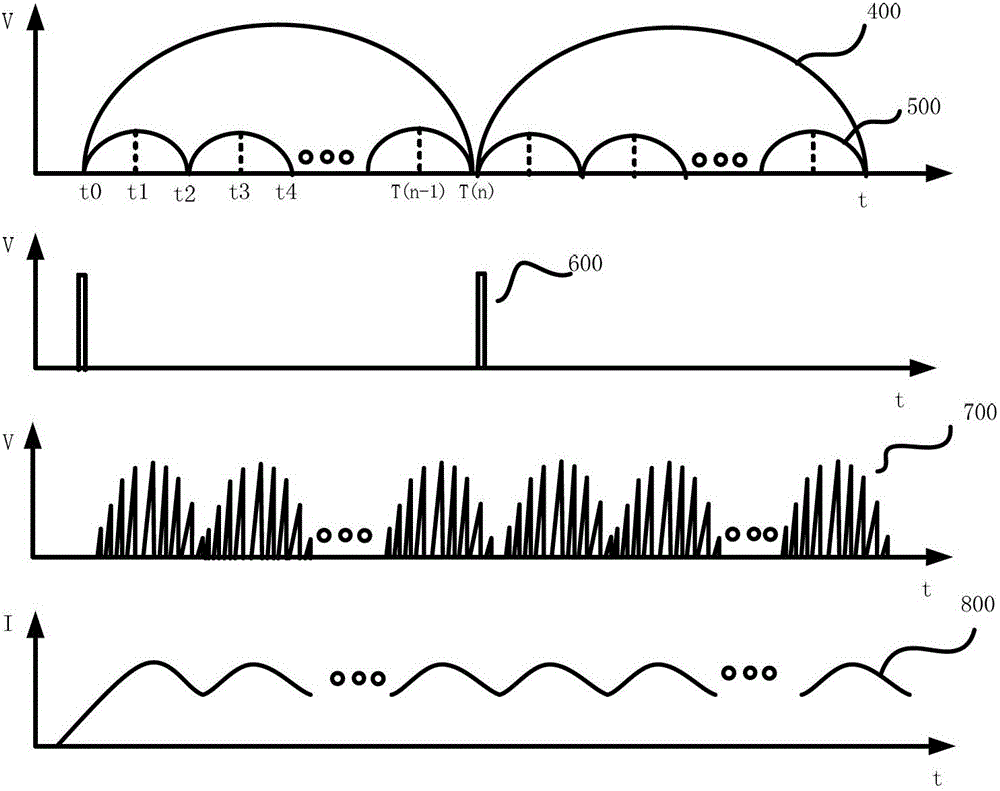

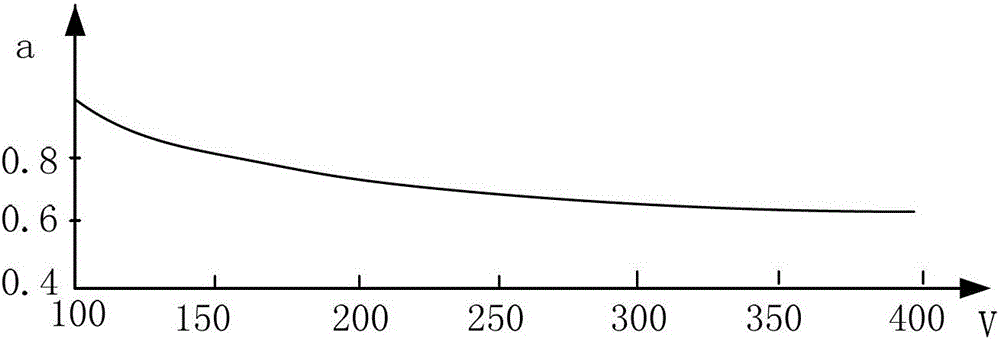

[0042] A sampling control module 210 that samples the peak value of the input AC voltage and outputs a current reference curve whose frequency is at least twice the frequency of the input AC;

[0043] Receiving the voltage value of the main-stage inductance series resistance of the peripheral drive circuit, receiving the current reference curve output by the sampling control module 210, comparing the voltage value of the main-stage inductance series resistance of the peripheral drive circuit with the corresponding voltage value on the current reference curve, and outputting the comparison result Comparator 220;

[0044] A logic control module 240 that receives the comparison result output by the comparator 220 and outputs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com