Tableware rotation and soak cleaning method, and rotation dish washing machine

A dishwashing machine and tableware technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and washing machine parts, cleaning equipment, etc., can solve stubborn stains without cleaning ability, poor cleaning effect, low speed low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: Single cylinder and single frame

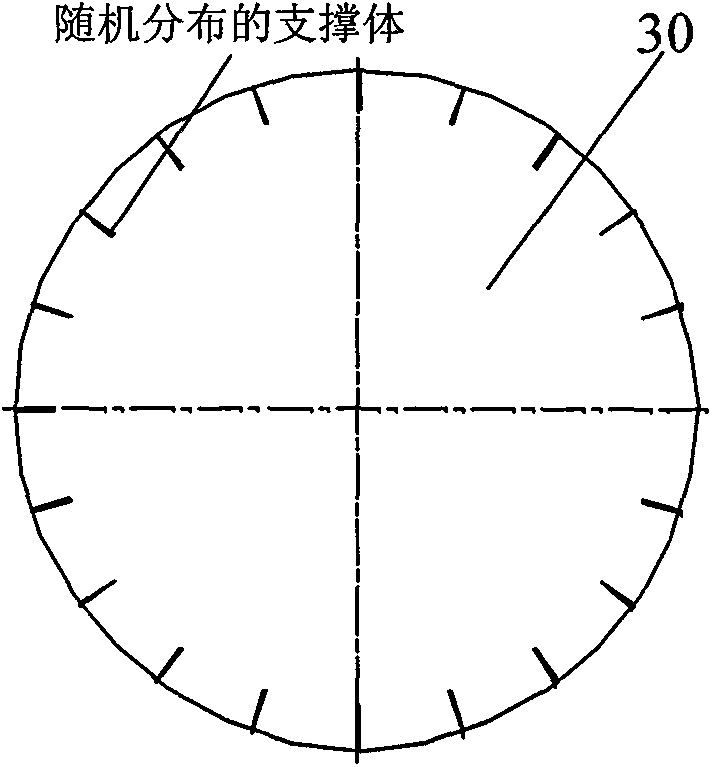

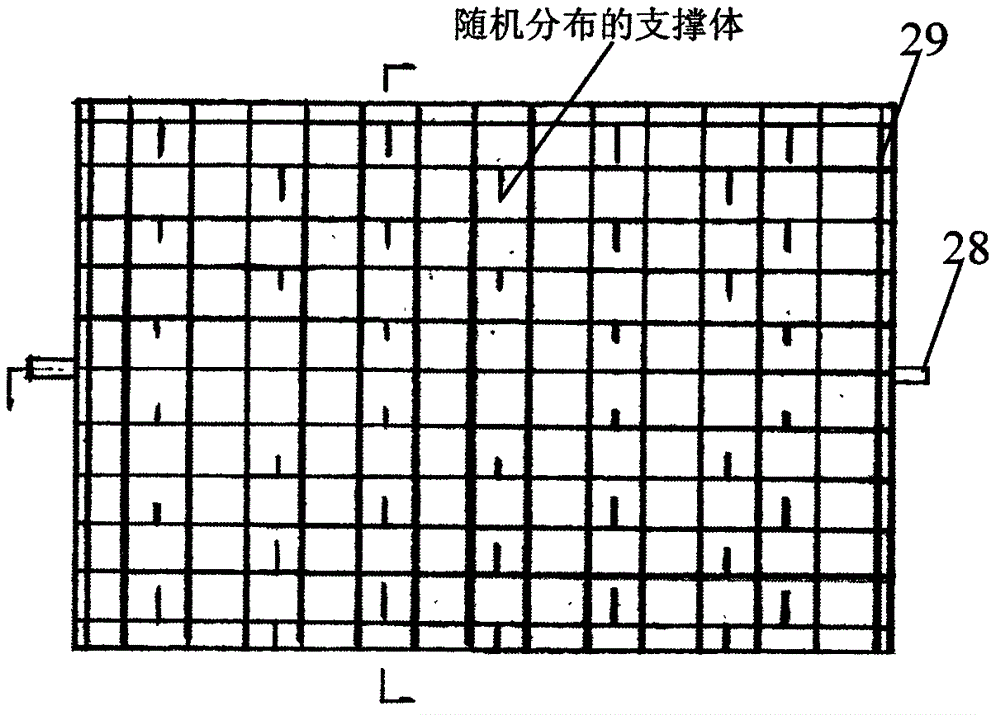

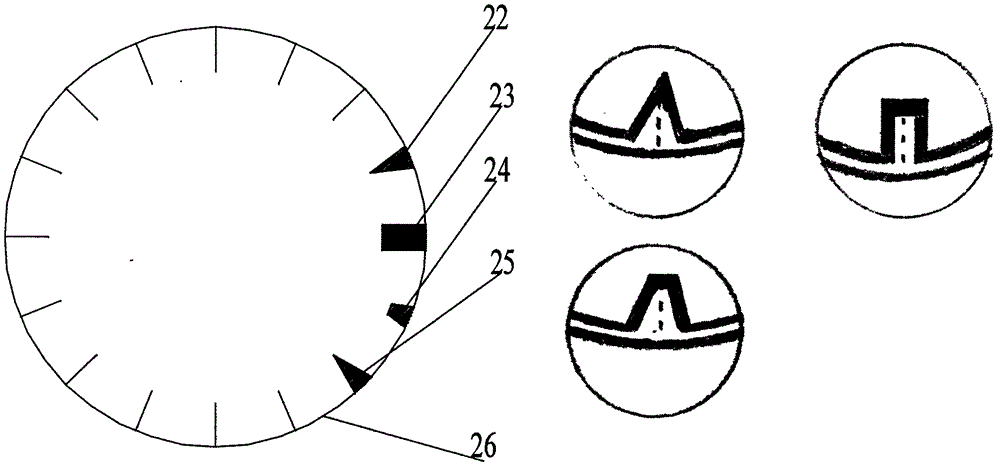

[0054] The dishwasher has a cylinder body, and there is a hanging frame inside the cylinder. The hanging frame is made of stainless steel wire braided, stamped, and welded. It is horizontally installed on the cylinder wall and driven to rotate by a motor and a reducer. Embedded computer control.

Embodiment 2

[0055] Example 2: Single cylinder with multiple frames

[0056] The dishwasher has a cylinder body, and there are two hanging frames in the cylinder body. The suspension frames are made of stainless steel wire weaving, stamping, and welding. They are installed horizontally and side by side on the cylinder wall, and are driven by a set of motors and reducers. , The dishwasher is controlled by an embedded computer, suitable for large-scale cleaning.

Embodiment 3

[0057] Embodiment 3: Double cylinder single frame

[0058] The dishwasher has two tanks, and each tank has a hanging frame, which is made of stainless steel wire weaving, stamping and welding, and is installed horizontally on the tank wall, driven by a set of motors and reducers Rotary, the dishwasher is controlled by an embedded computer, suitable for sorting washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com