Novel efficient dewatering bin and dewatering method

A dehydration silo, high-efficiency technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of clogging of dehydration silo, small dehydration area, low dehydration efficiency, etc., to achieve smooth drainage, prolong service life, and dehydration efficiency. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

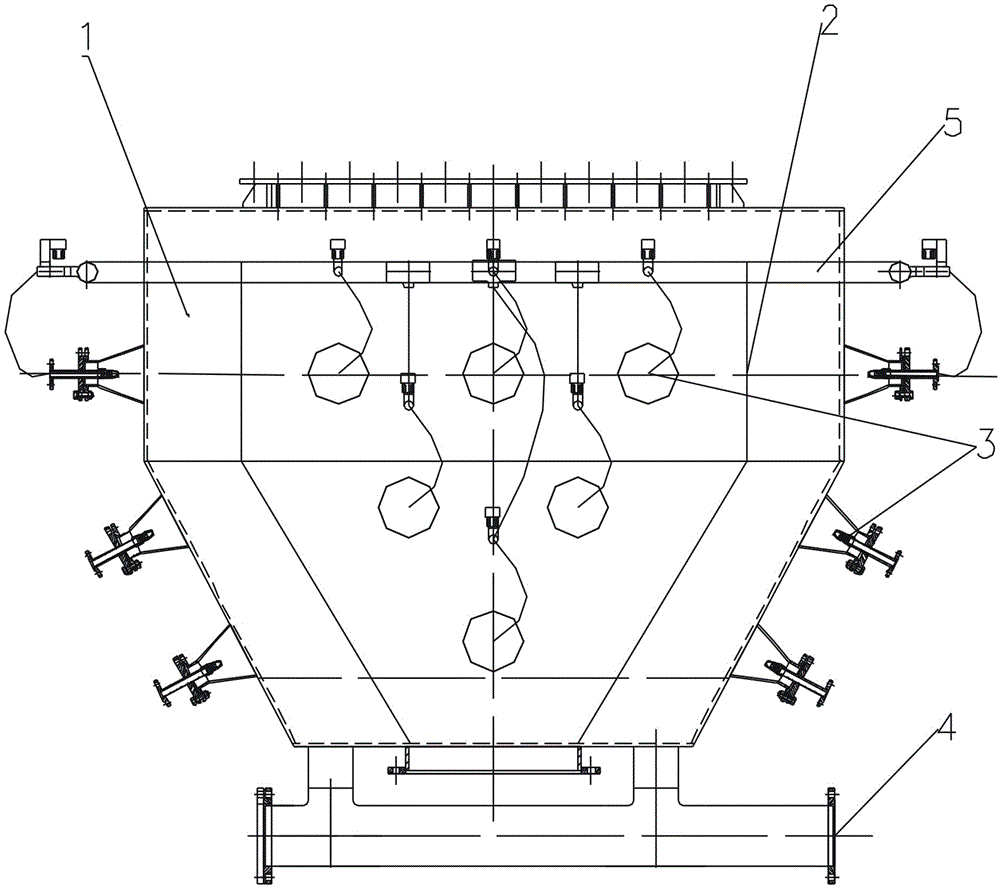

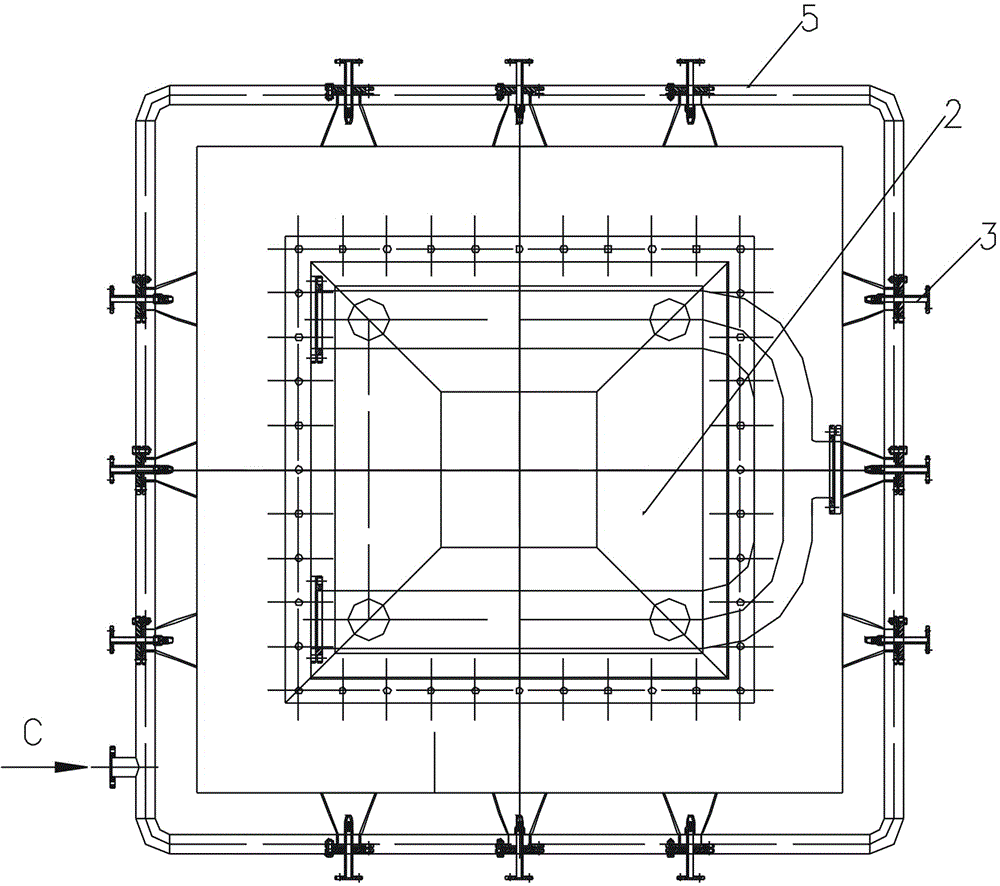

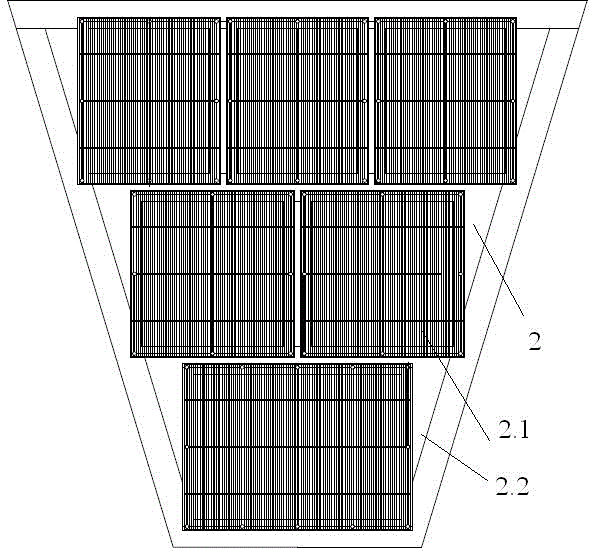

[0021] Such as Figure 1-3 The new high-efficiency dehydration chamber shown is characterized in that: the dehydration chamber is independently installed under the water slag chamber in a single chamber; it is mainly composed of a shell 1, a dehydration plate 2, a recoil cleaning valve 3, a drain pipe 4, and a water inlet pipe 5 The upper part of the shell 1 is a square cylinder, the lower part is connected from top to bottom to form a funnel-shaped tetrahedron, and the bottom is flat and provided with a bottom opening; the dehydration plate 2 has the same shape as the shell 1 and is placed in the shell 1 at intervals; The top and bottom openings of the shell 1 are provided with flanges, the top flange is connected to the interface of the upper water slag bin, and the bottom flange is connected to the slag discharge device; a plurality of recoil cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com