Special grinding wheel for liquid crystal glass

A liquid crystal glass, grinding wheel technology, applied in abrasives, bonded grinding wheels, metal processing equipment, etc., to achieve the effect of improving electrical conductivity, reducing groove deformation, and reducing intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

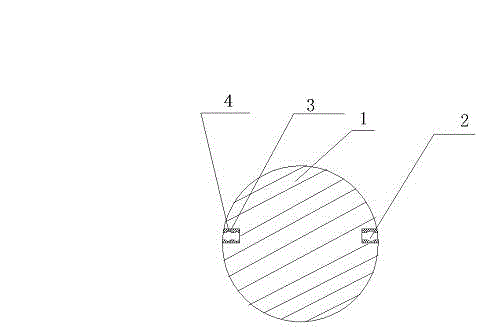

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in the figure, a special grinding wheel for liquid crystal glass includes a diamond edging wheel 1, the outer peripheral surface of the diamond edging wheel 1 is provided with a plurality of concave arc-shaped grinding grooves 2, and the groove wall of the grinding groove 2 is provided with There is a copper coating 3, the thickness of which is 25 μm, and a concave arc-shaped groove 4 is provided on the groove wall of the grinding groove 2.

[0015] During processing, firstly, design the groove shape, use a CNC lathe to carve out the corresponding groove shape on the tool electrode according to the design, and use a copper disc as the tool electrode to improve the conductivity and reduce the intermediate links of processing, thereby reducing the deformation of the groove shape ;Secondly, use the CNC EDM to process the special edging wheel for liquid cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com