Sludge extrusion dewatering testing machine and using method thereof

A technology of extrusion dehydration and testing machine, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of many influencing factors, large influence, and heavy labor, and achieve controllable influencing factors, increased number of tests, and high test efficiency. The effect of less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

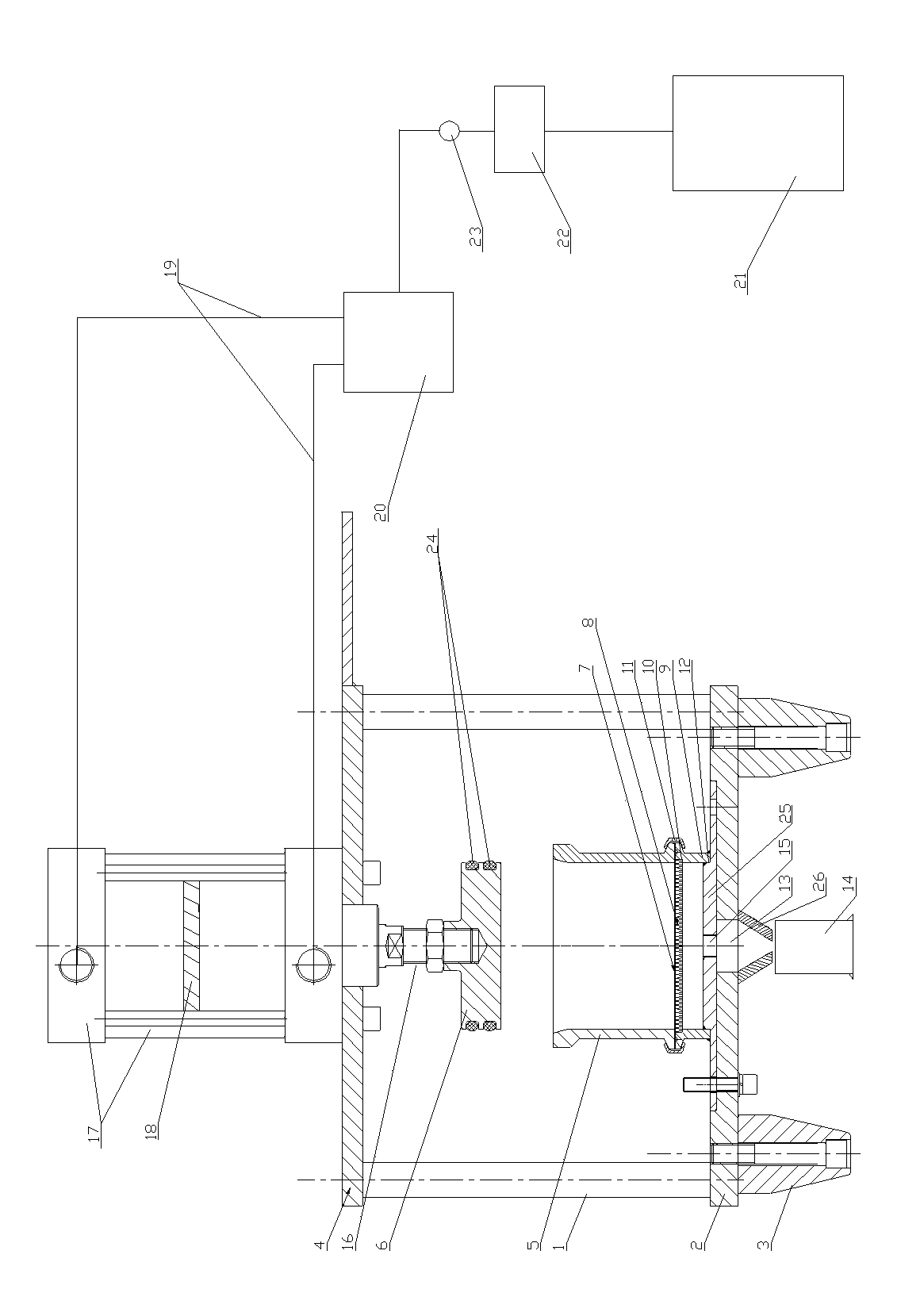

[0021] A sludge extrusion dehydration test machine, which includes a frame 1, a leg 3 is installed on the lower end surface of the bottom plate 2 of the frame 1, and a sludge cup 5 is arranged in the cavity between the upper plate 4 and the bottom plate 2 of the frame , the extrusion plate 6, the bottom of the sludge cup 5 is hollowed out, the bottom cover of the sludge cup 5 is equipped with a filter cloth 7, the filter cloth 7 is supported on the chassis 8, the chassis 8 is evenly distributed with micropores, and the outer ring part of the chassis 8 is installed In the annular mounting groove 10 of the bracket 9, the quick-connect flange 11 is fastened to connect the bottom end surface of the sludge cup 5 and the top surface of the bracket 9, and the bottom ring surface of the bracket 9 is positioned and connected to the positioning bayonet 12 on the upper end surface of the bottom plate 2 , the center of the bottom plate 2 is provided with a through hole 13, the through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com