Method for preparing collagen modified regenerated cellulose composite material

A technology of regenerated cellulose and regenerated cellulose film, applied in medical science, absorbent pads, prostheses, etc., can solve problems such as weak bonding and unstable performance of composite materials, and achieve rapid healing, moisturizing and moisture permeability Good effect of promoting proliferation and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

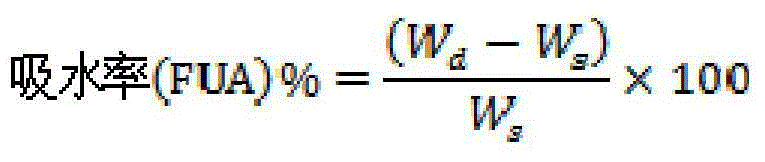

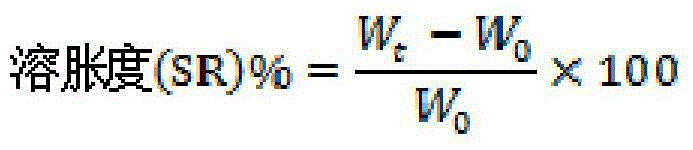

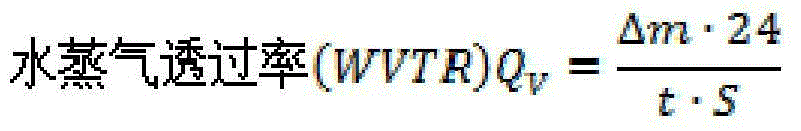

[0057] NaOH / urea / water (7wt% / 12wt% / 81wt%) solvent system was used to dissolve natural cellulose with a degree of polymerization of 500 to obtain a 4wt% cellulose solution, which was used to prepare a regenerated cellulose membrane. The regenerated cellulose membrane was washed several times with deionized water to remove residual inorganic salts and other impurities. Then soak the regenerated cellulose membrane in a sodium periodate aqueous solution with a concentration of 1wt%, adjust the pH to 1, and react at 15°C for 15 minutes. The water is washed repeatedly to obtain the regenerated cellulose membrane with C2 and C3 aldehydes. Then react the aldylated regenerated cellulose membrane with 0.05% collagen solution at 4°C for 30 minutes, take it out, wash off the residual collagen on the surface with deionized water, and freeze-dry to obtain the collagen-modified regenerated cellulose composite material . The properties of the prepared composite materials are shown in Table ...

Embodiment 2

[0059] The NaOH / urea / water (7wt% / 12wt% / 81wt%) solvent system was used, and the method was the same as in Example 1. The regenerated cellulose membrane was washed several times with deionized water to remove residual inorganic salts and other impurities. Then soak a certain amount of regenerated cellulose film in a sodium periodate aqueous solution with a concentration of 3wt%, adjust the pH to 2, and react at 20°C for 30 minutes. After the reaction is completed, soak in ethylene glycol to remove the residual sodium periodate, and then Repeated washing with deionized water to obtain the regenerated cellulose membrane with C2 and C3 aldehydes. Then react the aldylated regenerated cellulose membrane with 0.2% collagen solution at 10°C for 1 hour, take it out, wash off the remaining collagen on the surface with deionized water, and freeze-dry to obtain the collagen-modified regenerated cellulose composite material . The properties of the prepared composite materials are shown in...

Embodiment 3

[0061] The NaOH / urea / water (7wt% / 12wt% / 81wt%) solvent system was used, and the method was the same as in Example 1. The regenerated cellulose membrane was washed several times with deionized water to remove residual inorganic salts and other impurities. Then soak a certain amount of regenerated cellulose film in a sodium periodate aqueous solution with a concentration of 3wt%, adjust the pH to 3, and react at 25°C for 1 hour. After the reaction is completed, soak it in ethylene glycol to remove the residual sodium periodate, and then Repeated washing with deionized water to obtain the regenerated cellulose membrane with C2 and C3 aldehydes. Then react the aldylated regenerated cellulose membrane with 0.2% collagen solution at 15°C for 2 hours, take it out, wash off the remaining collagen on the surface with deionized water, and freeze-dry to obtain the collagen-modified regenerated cellulose composite material . The properties of the prepared composite materials are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com