Polystyrene foam plastic board for thermal insulating layers of geothermal floors

A technology of foam plastic board and polystyrene, applied in the direction of insulation layer, building materials, etc., can solve the problems of poor heat transfer, achieve the effects of preventing local overheating, uniform heating, and increasing gas flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

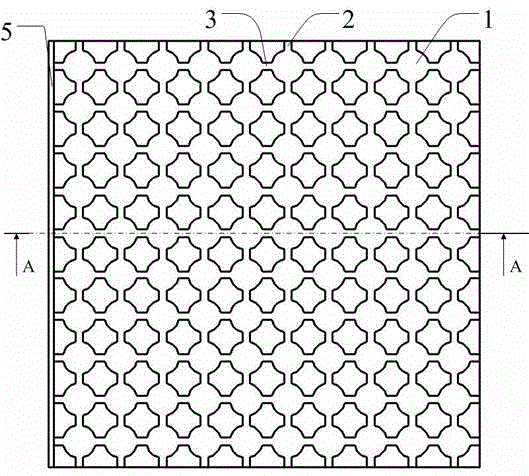

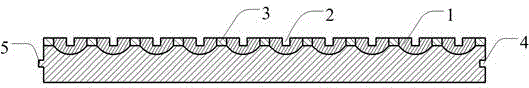

[0021] A polystyrene foam plastic board used for geothermal floor insulation, the thickness of the polystyrene foam plastic board is 4cm, and circular grooves with a diameter of 3cm are distributed on its upper surface in a square lattice of 4cm×4cm. The depth of the circular grooves is 1.2cm, and each circular groove is connected through the horizontal and vertical ventilation grooves perpendicular to each other. The width of the horizontal and vertical ventilation grooves is 0.8cm, and the depth is 0.7cm. A tenon is provided on one side of the plastic plate, and a corresponding tenon is provided on the opposite side.

Embodiment 2

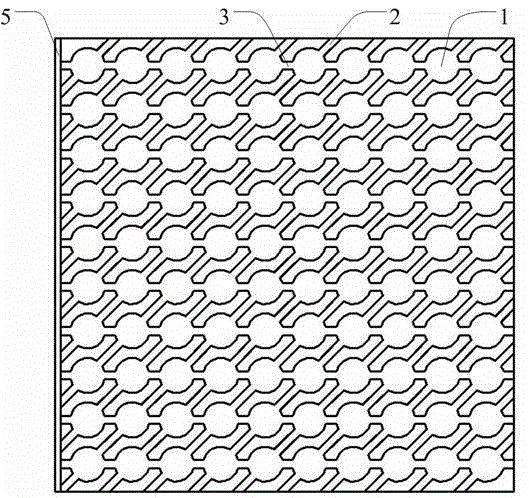

[0023] like image 3 As shown, a polystyrene foam plastic board used for geothermal floor insulation layer, the thickness of the polystyrene foam plastic board is 4cm, and the circular dots with a diameter of 3cm are distributed on the upper surface according to the square lattice of 5cm×5cm. Groove, the depth of the circular groove is 1.2cm, and each circular groove is connected to each other through the horizontal ventilation groove and the vertical ventilation groove. The included angle between the ventilation groove and the longitudinal ventilation groove is 45 degrees, a tenon is arranged on one side of the foam plastic plate, and a corresponding tenon is arranged on the other side opposite to it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com